LED patch bracket

A technology of LED patch and LED chip, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of light loss, affecting brightness, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

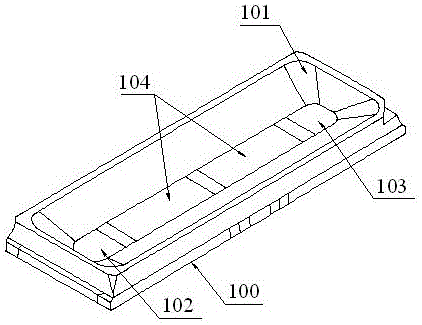

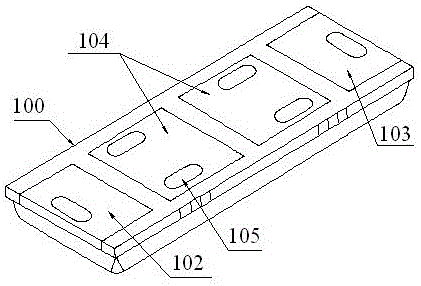

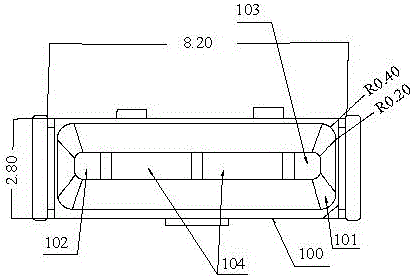

[0020] refer to Figure 1 to Figure 5 , an embodiment of an LED patch bracket of the present invention is proposed, which includes a bracket body 100 with a bowl inside, and a number of LED chips can be installed on the bottom of the bowl of the bracket body 100, and installed in the bowl behind the LED chip Can be filled with fluorescent glue.

[0021] The inner surface of the cup of the bracket body 100 has an inverted trapezoidal structure. The corners of the inverted trapezoidal structure are set as arc-shaped corners 101 which are beneficial to improve light efficiency and luminous uniformity. The corners of the bowls of the LED patch brackets on the market are generally in the form of straight lines and flat angles, resulting in a large loss of brightness at the corners, reducing light efficiency, and the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com