Positive and negative pressure-relief battery core

A technology of positive and negative electrodes and battery cells, which is applied in the field of positive and negative electrode discharge cores, can solve the problems of affecting the battery cells, the explosion of the battery cells, the bursting of the battery cells, etc., and achieves the effects of reasonable design, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

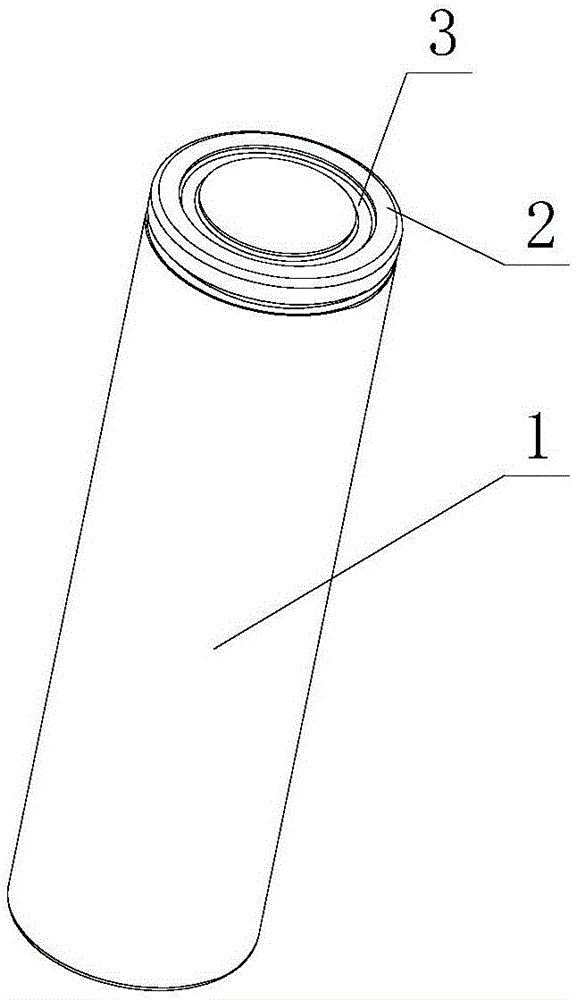

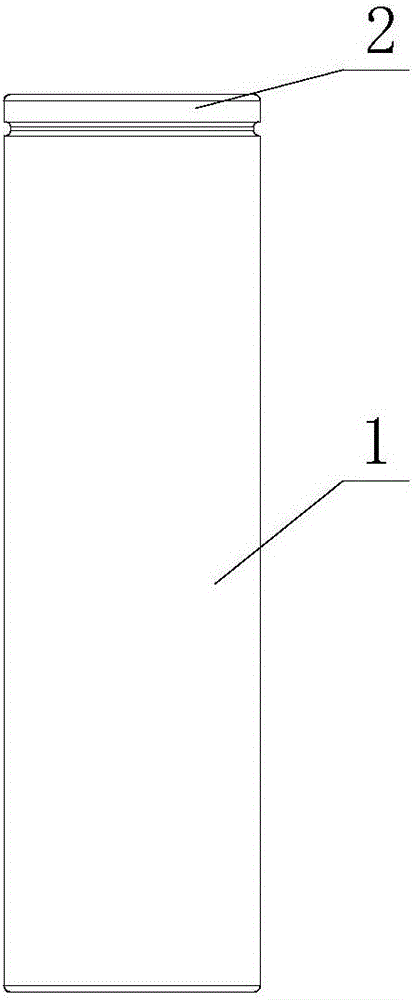

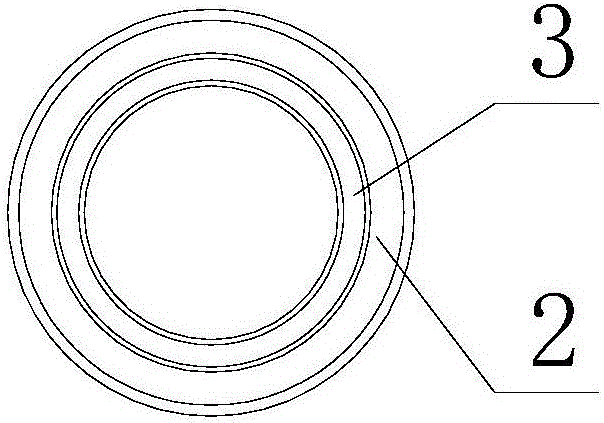

[0022] like figure 1 , figure 2 , image 3 , Figure 4 The shown positive and negative pressure relief cells include a cell body 1, one end of the cell body 1 is provided with a positive end face 2, the other end of the cell body 1 is provided with a negative end face 4, and the positive end face 2 is provided with a positive groove 3. The negative electrode surface 4 is provided with a negative electrode groove 5 engraved by a laser. The depth of the negative electrode groove 5 is 0.08-0.15 mm, preferably 0.1 mm. The negative electrode groove 5 is C-shaped.

Embodiment 2

[0024] like figure 1 , figure 2 , image 3 , Figure 5 and Image 6 The shown positive and negative pressure relief cells include a cell body 1, one end of the cell body 1 is provided with a positive end face 2, the other end of the cell body 1 is provided with a negative end face 4, and the positive end face 2 is provided with a positive groove 3. The negative electrode surface 4 is provided with a negative electrode groove 5 engraved by a laser. The depth of the negative electrode groove 5 is 0.15 mm, and the negative electrode groove 5 is a combination of a C shape and a straight line.

Embodiment 3

[0026] like figure 1 , figure 2 , image 3 , Figure 7 The shown positive and negative pressure relief cells include a cell body 1, one end of the cell body 1 is provided with a positive end face 2, the other end of the cell body 1 is provided with a negative end face 4, and the positive end face 2 is provided with a positive groove 3. The negative electrode surface 4 is provided with a negative electrode groove 5 engraved by a laser. The depth of the negative electrode groove 5 is 0.08mm, and the negative electrode groove 5 is Y-shaped.

[0027] The present invention is simple in structure, reasonable in design, and easy to operate. Because the thickness of the negative groove of the cell is smaller than that of its periphery, it is easy to burst the negative groove when the battery explodes; similarly, the thickness ratio of the positive groove is The thickness of its periphery is small, and when the cell explodes, it is easy to burst the positive groove, so the heat can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap