Spinning machinery distribution box with concealed lifting and cooling mechanism

A heat dissipation mechanism and hidden technology, which is applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve the problems of dust entering the box, low heat dissipation efficiency, and reduced air output, etc., to achieve Effects of preventing dust ingress, improving heat dissipation, and improving dust resistance

Active Publication Date: 2017-02-22

盐城凌云驿站科技有限公司

View PDF4 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is: in order to solve the problems existing in the above-mentioned background technology, an improved textile machinery distribution box with a hidden lifting and cooling mechanism is provided to solve the problem that most of the current distribution boxes use filter screens to add heat dissipation. Although this method takes into account both dustproof and heat dissipation to a certain extent, dust will still enter the box when the power distribution box is low or not working, and in the case of high power and high heat , the filter screen will reduce the air volume, resulting in the problem of low cooling efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

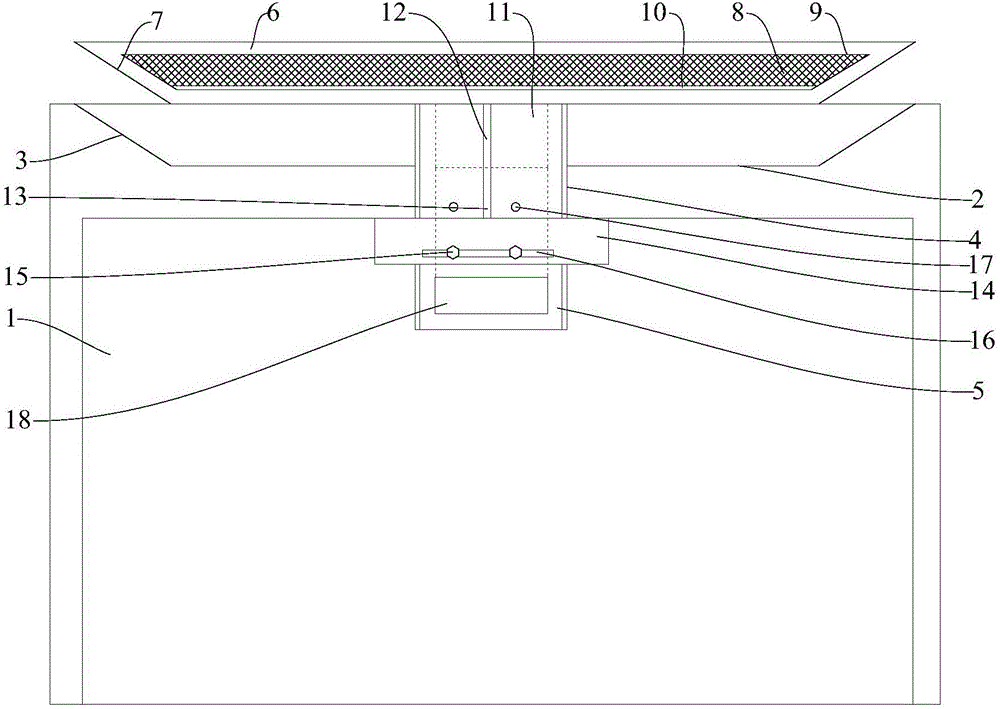

[0015] Embodiment: The small vacuum pump 11 is powered by the power supply inside the distribution box, connected in series with the internal power supply through the power connection line, and is turned on and off synchronously with the internal power supply.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

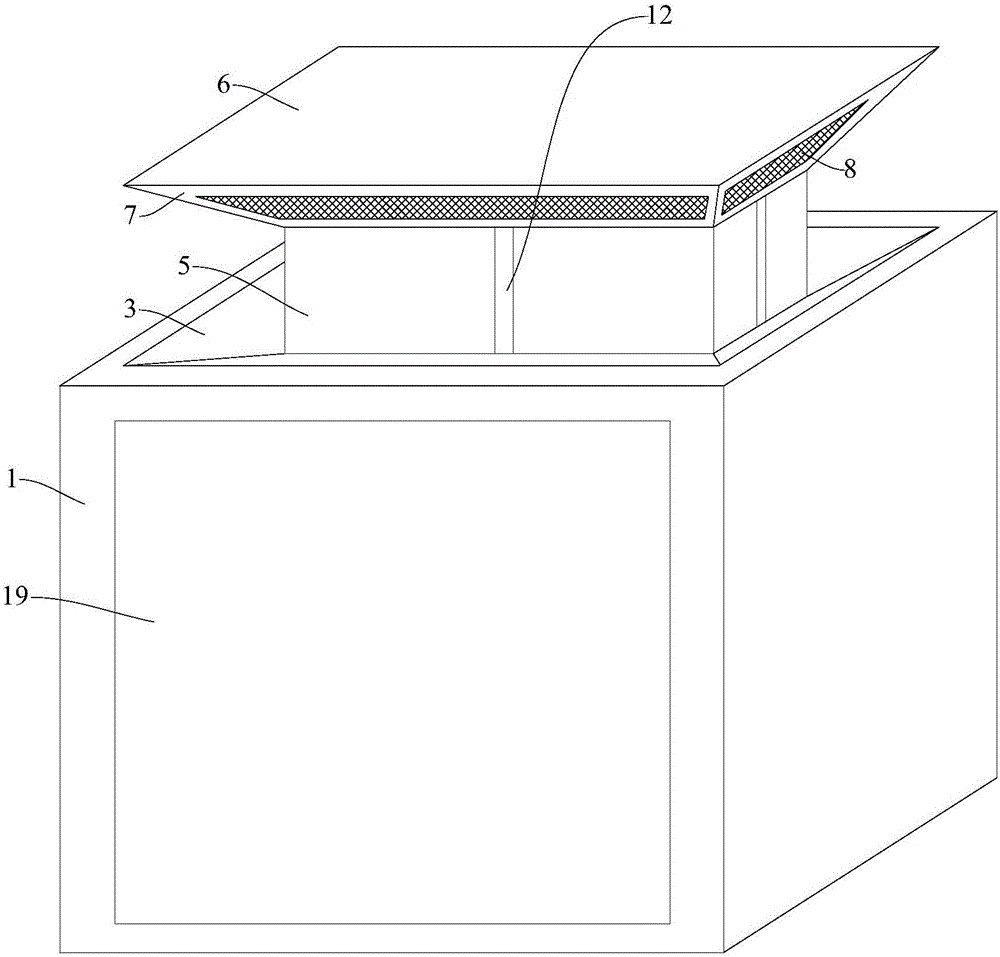

The invention relates to the technical field of textile machine auxiliary apparatuses, in particular to a textile machinery distribution box with a concealed lifting and cooling mechanism. The distribution box comprises a casing, and the upper surface of the casing is provided with a lifting accommodation groove. According to the textile machinery distribution box of the present invention, the lifting accommodation groove with a built-in lifting box is arranged on the top of the box body, and the height of the lifting pipe in the box body is adjusted as required by the fixing bolts on the built-in fixing plate. The air suction positions can be changed due to different heating amount, so that the internal heat radiation efficiency can be effectively improved. By means of the elastic rotary shaft, the metal filter screen is mounted in a heat radiation outlet, airflow at the heat radiation outlet can be increased at the state of high flow, so that the heat radiation can be increased, the lifting box body can descend into the lifting accommodation groove under the condition of low consumption or idle operation, the heat radiation outlet is totally sealed to prevent dust from entering the box body, and dustproof-ness can be greatly improved.

Description

technical field [0001] The invention relates to the technical field of textile machinery auxiliary equipment, in particular to a textile machinery power distribution box with a hidden lifting and cooling mechanism. Background technique [0002] In the current textile industry, a large number of textile machines need to be used. In order to improve the working stability and safety of all textile machines and facilitate later inspection and maintenance, it is necessary to set up a special distribution box. As a result, a large amount of heat energy is generated inside the distribution box, and there will be a large amount of dust floating objects in the environment where the distribution box is located. The heat dissipation method of the radiator, although this method takes into account the dust resistance and heat dissipation to a certain extent, but the dust will still enter the inside of the box when the power distribution box is low or not working, and in the case of high ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02B1/56H02B1/28H02B1/46

CPCH02B1/28H02B1/46H02B1/56

Inventor 顾光旭李家荣陈前进

Owner 盐城凌云驿站科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com