High-speed rotating cooling machine with structure for quickly disassembling and assembling target piece

A high-speed rotating and cooling machine technology, applied in cooling/ventilation/heating transformation, DC voltage accelerators, targets for generating nuclear reactions, etc., can solve the problems that plague designers, avoid radiation hazards, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For ease of understanding, here in conjunction with accompanying drawing, to the concrete implementation structure of the present invention, be further described as follows:

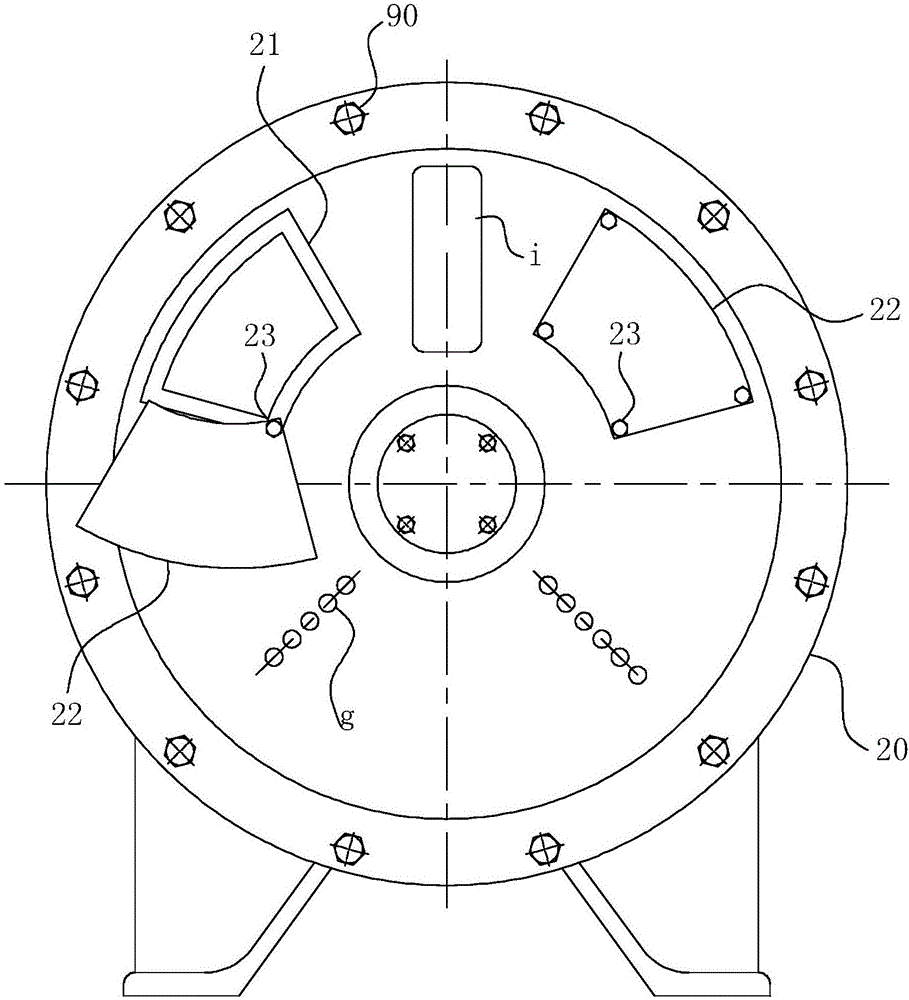

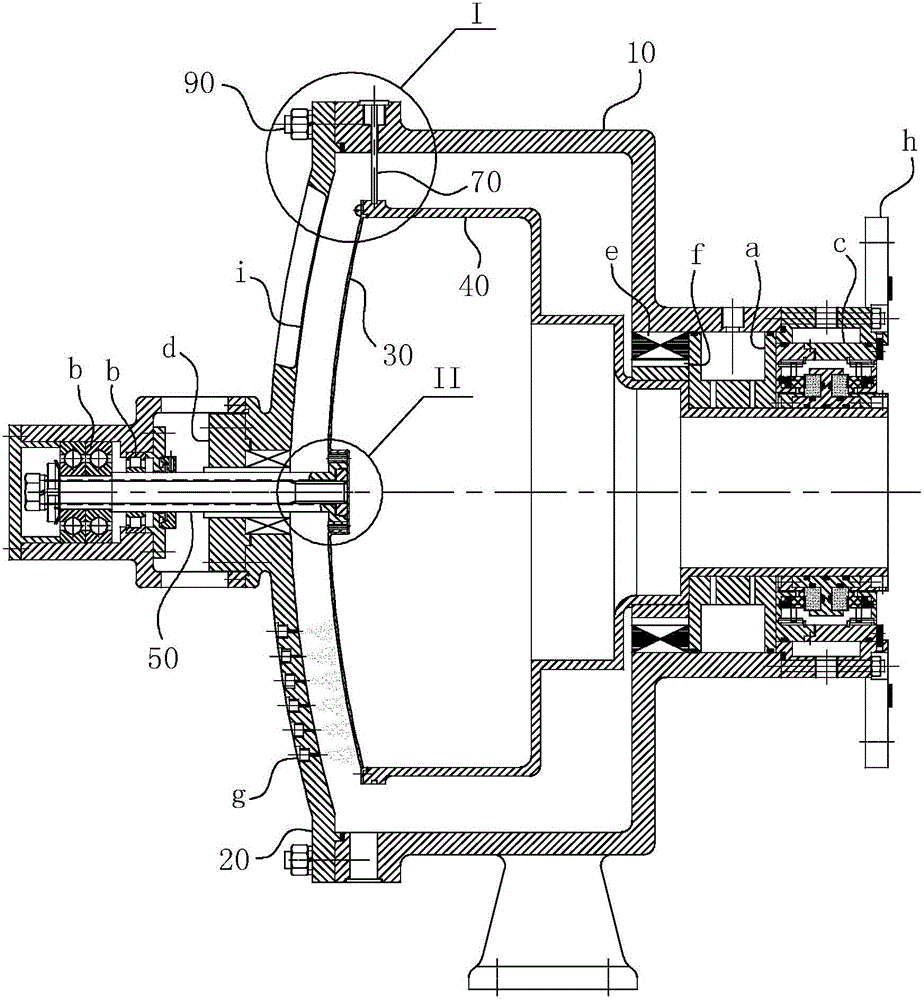

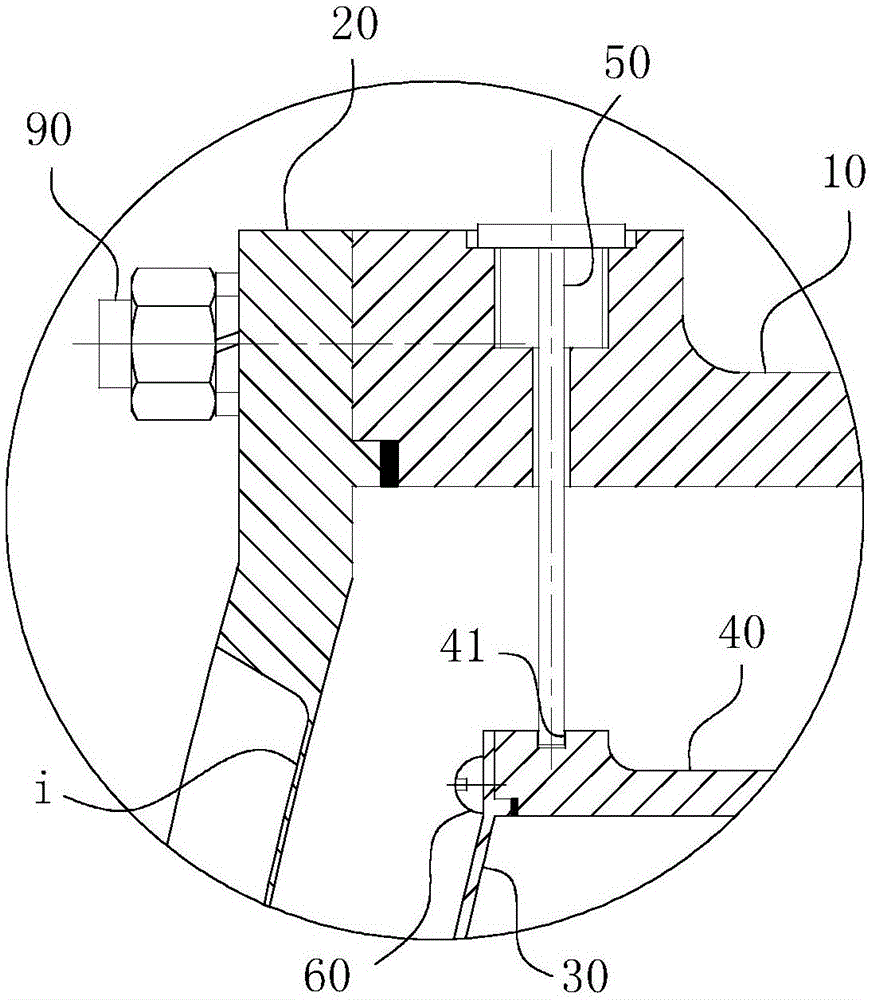

[0031] Concrete structure of the present invention, as Figure 1-4 As shown, its overall structure is a support structure at both ends, mainly composed of air bearing a, rolling bearing b, dry gas seal c, contact mechanical seal d, stator e, rotor f, rotating cavity (that is, sleeve-shaped bracket 40 ), the cooling machine shell (that is, the outer shell 10), the shell cover 20, the nozzle g, the target piece 30 and the connecting flange h and so on.

[0032] Among them, such as figure 1 As shown, the power unit of the device is mainly composed of a stator e and a rotor f. The rotor f is directly hooped on the sleeve-shaped bracket 40, which ensures the reliability and compactness of the driving structure. The radial support of this device is provided by the figure 2 The air bearing a on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com