Clutch disk comprising a centrifugal pendulum

A technology of clutch disc and centrifugal force pendulum, which is applied in clutches, friction clutches, mechanically driven clutches, etc., and can solve problems such as residual vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

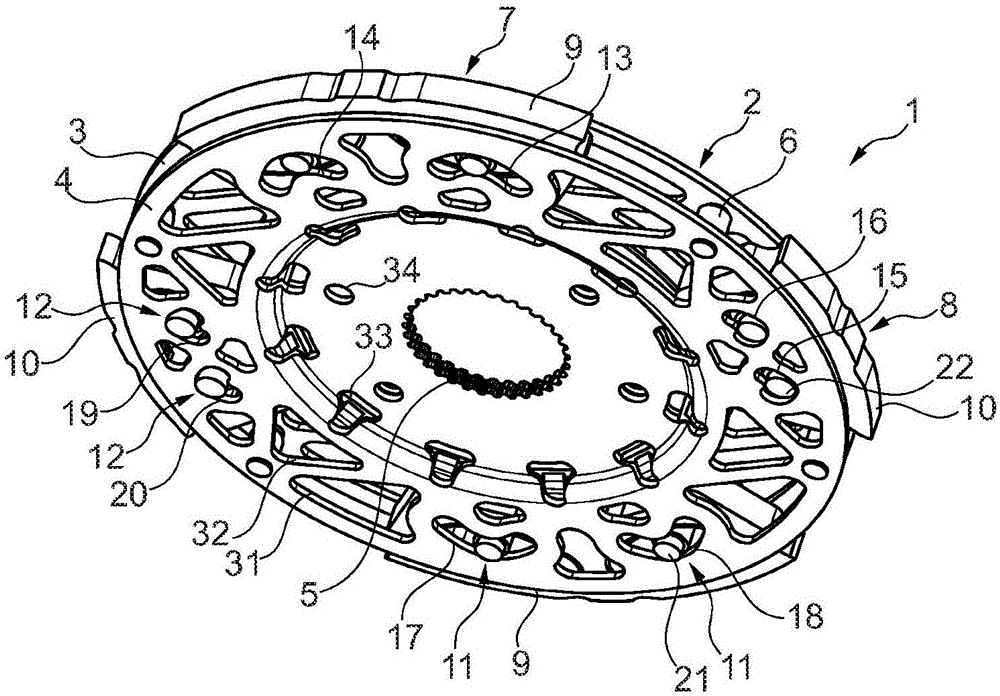

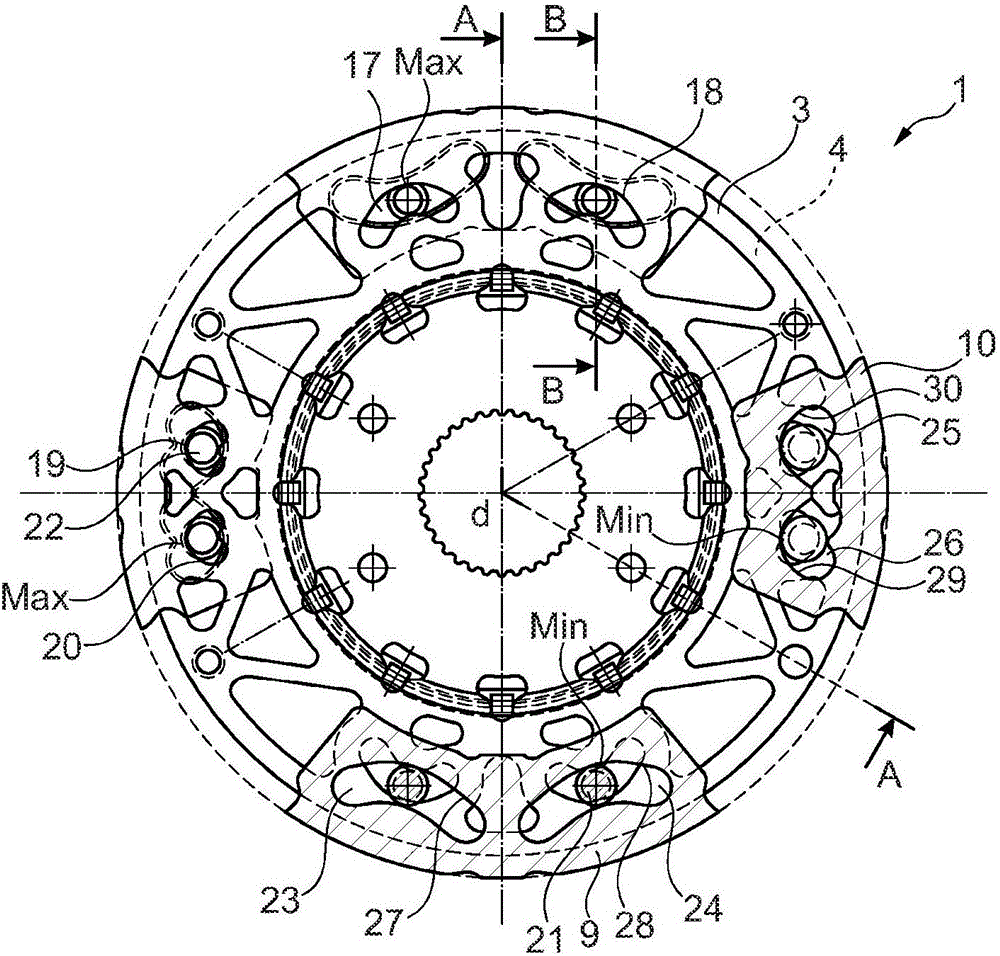

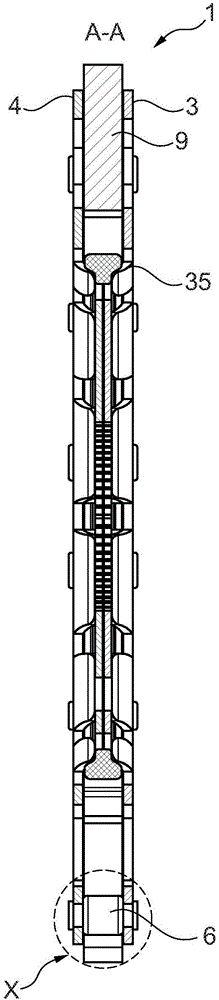

[0020] figure 1 The centrifugal pendulum 1 is shown in a perspective view and is held in a rotationally fixed manner on the hub of a clutch disk (not shown). The rest of the design of the clutch disk is known and can be obtained, for example, from the cited prior art. Centrifugal pendulum 1 comprises a support 2 formed from two disk parts 3 , 4 which are preferably designed as identical parts. The centrifugal pendulum 1 is held on the hub in a rotationally fixed manner by means of the inner toothing 5 of the disk parts 3 , 4 and is fixed in the axial direction, for example by caulking. The disk parts bear against each other radially on the inside and widen in the axial direction on the radial outside and are connected to one another at a distance in the axial direction by means of spacer pins 6 . In the axial direction, two pendulum groups 7 , 8 are accommodated between the two disk parts 3 , 4 . The pendulums 9 , 10 of the two pendulum groups 7 , 8 are each arranged diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com