High conductance valve for fluids and vapors

A fluid and fluid volume technology, used in lift valves, multi-way valves, valve devices, etc., to solve problems such as internal pollution sources on the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The invention is not limited in its application to the details of construction and arrangement of parts set forth in the following description and illustrated in the drawings. The invention is applicable to other embodiments and of being practiced or carried out in various ways. Also, the phraseology and terminology employed herein are for the purpose of description and should not be regarded as limiting. As used herein, "comprises," "including," or "having," "comprising," "involving," and variations thereof are intended to cover the items listed thereafter and equivalents thereof as well as additional items. The directional adjectives "inner", "outer", "upper", "lower" and similar terms are intended to aid in the understanding of relative relationships among design elements and should not be construed as indicating absolute directions in space or viewed as limiting of.

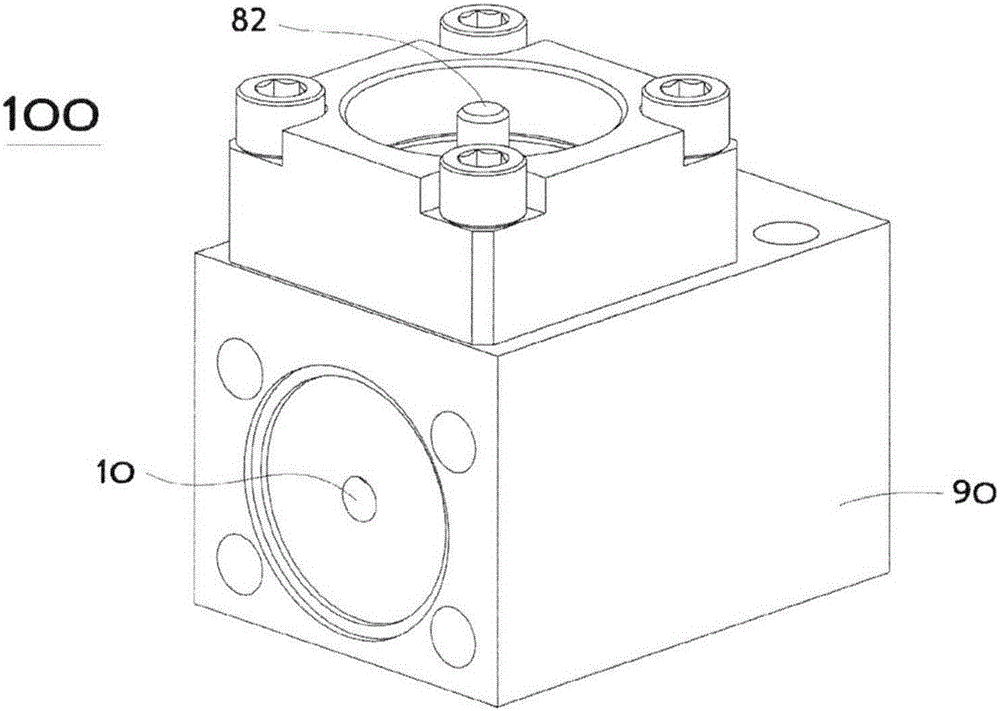

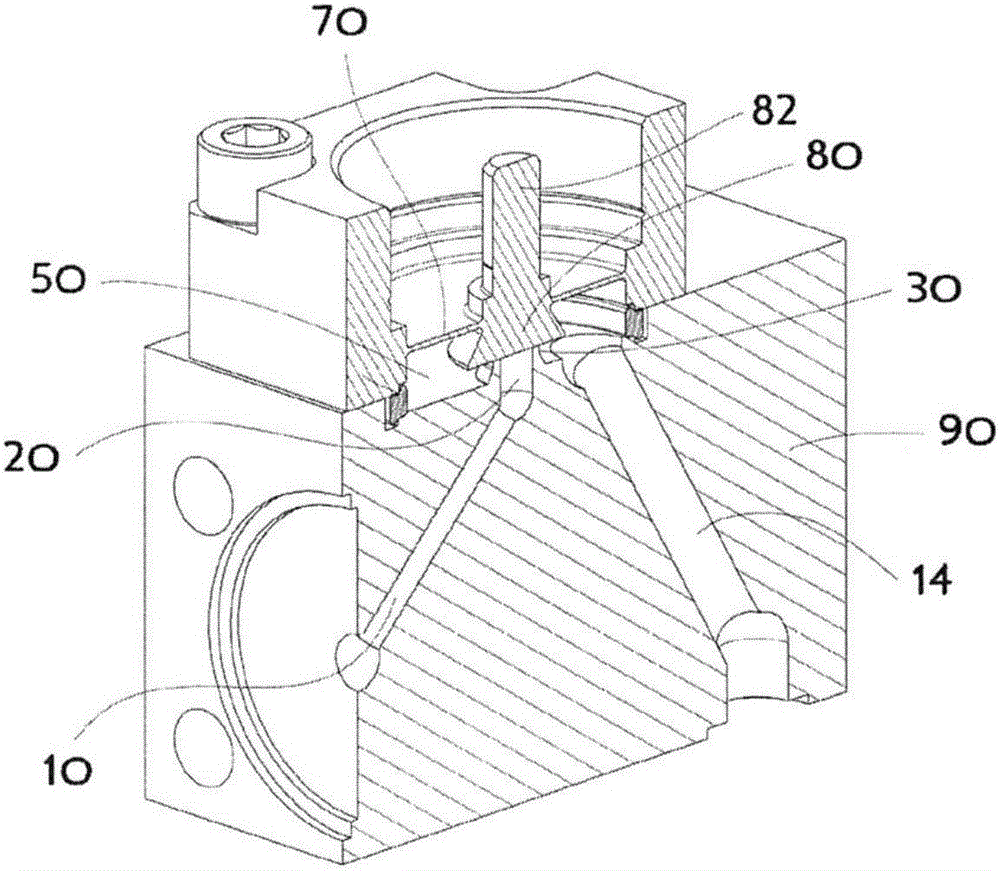

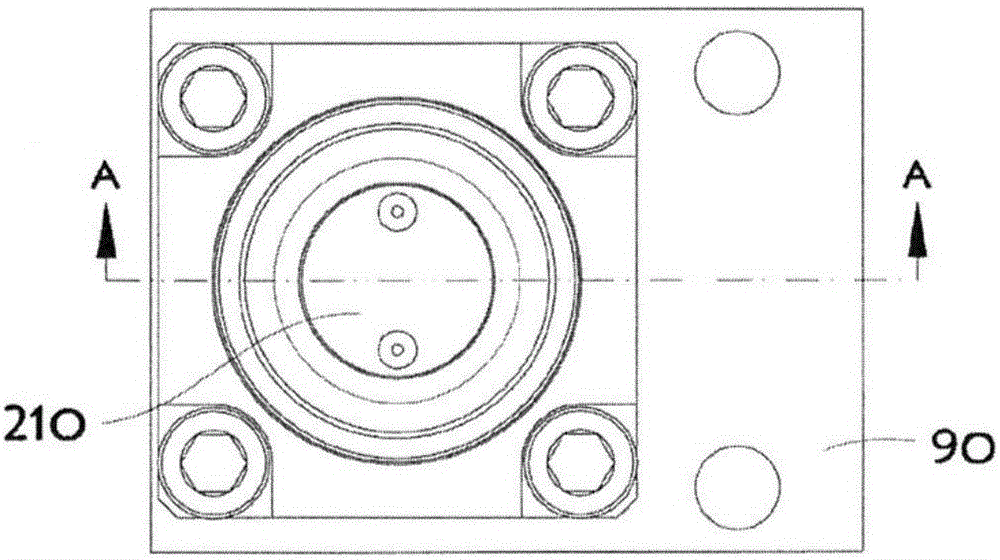

[0073] figure 1 and Figure 1A A representative example of a typical commonly used design valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com