Rotary table type conveyor for motor assembling

A transfer device and turntable technology, which is applied in the field of turntable transfer devices for motor assembly, can solve the problems of manual assembly and inconvenience, and achieve the effects of convenient operation, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

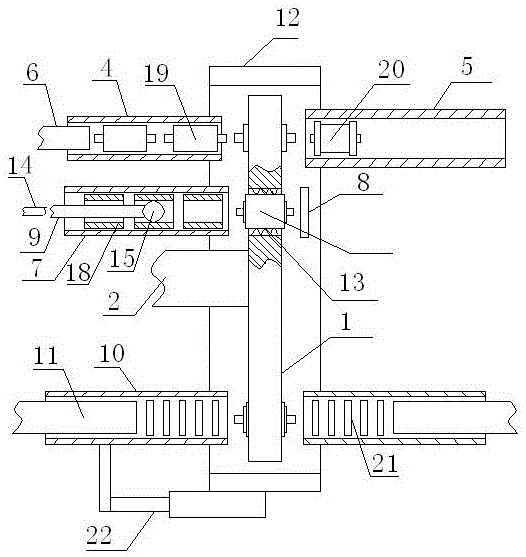

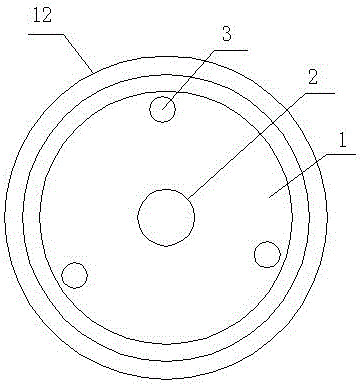

[0018] Such as figure 1 As shown, a turntable conveying device for motor assembly, including a turntable 1, the turntable axis 2 is in a horizontal state, driven by a motor to rotate. On the turntable, through holes 3 are distributed along the circumference of the turntable. Corresponding to the holes on the turntable, there are motor rotor feeding devices, motor stator feeding devices, and motor end cover feeding devices arranged on the side of the turntable. The motor rotor feeding device includes a motor rotor feeding tube 4 and a motor lowering tube 5 respectively arranged on both sides of the turntable, and a rotor push rod 6 that pushes the motor rotor forward along the feeding tube is arranged in the motor feeding tube. The motor stator feeding device includes a motor stator feeding tube 7 arranged on one side of the turntable and a motor rotor stopper 8 arranged on the turntable, and a motor stator 18 with an expansion end is provided in the motor stator feeding tube....

Embodiment 2

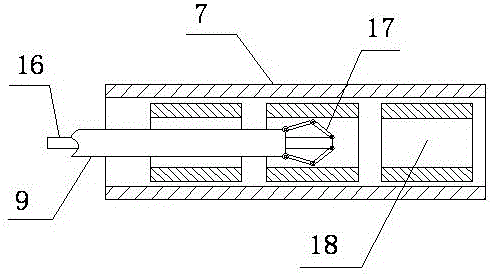

[0022] As shown in the figure, the difference from Embodiment 1 is that the motor stator push rod is a pipe body, and a telescopic rod 16 opposite to the pipe body is inserted in the pipe body, and the end of the pipe body and the end of the telescopic rod are connected by two Connecting rod 17, the connecting rod on the pipe body is hingedly connected with two connecting rods on the telescopic rod. When the telescopic rod moves relative to the push rod tube, the connecting rod expands or contracts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com