Automatic cutting and winding device and working method thereof

A coiling device and automatic cutting technology, applied in the direction of coiling strips, transportation and packaging, thin material processing, etc., can solve the problems of continuous coiling, strip falling off, low efficiency, etc., to avoid folding and deformation, avoid Falling off, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

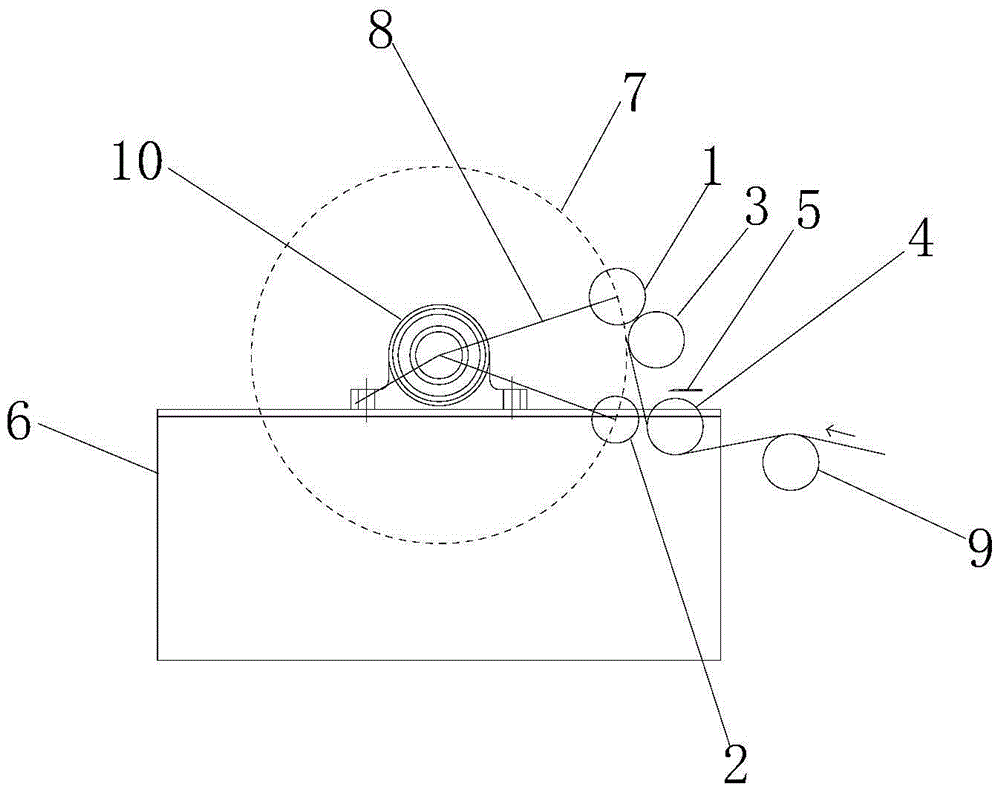

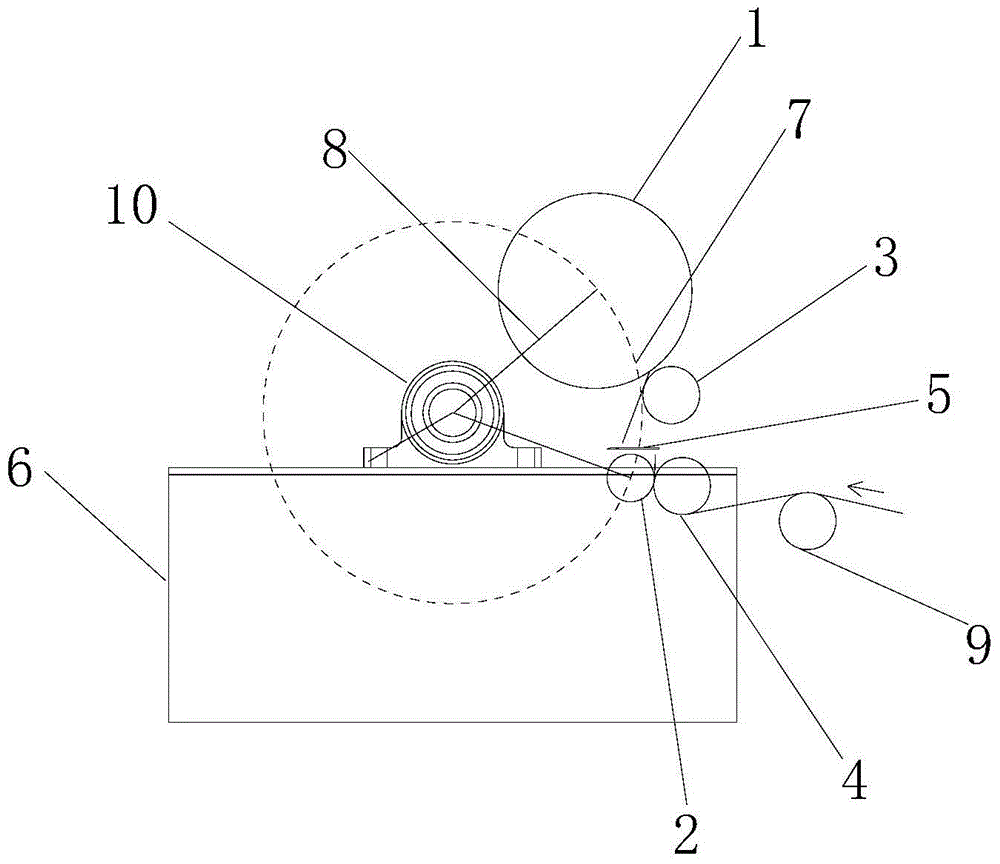

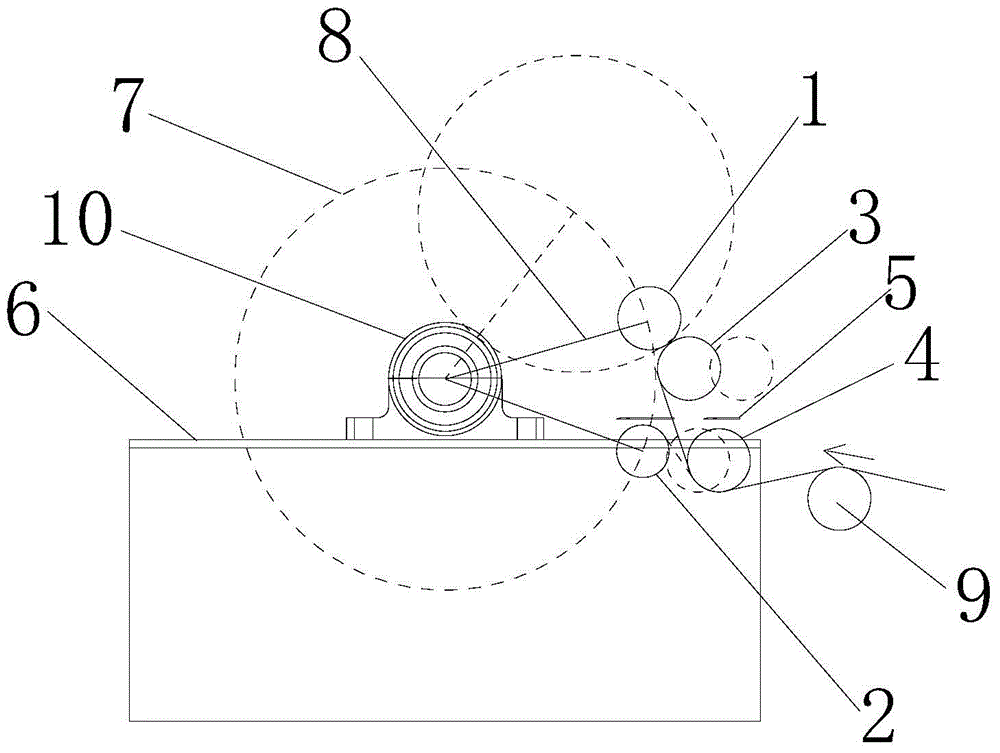

[0027] Example 1 as Figure 1-3 , the automatic cutting coiling device of the present embodiment includes a first coiling shaft 1, a second coiling shaft 2, a first pressing roller 3, a second pressing roller 4, a cutter 5 and a workbench 6.

[0028] The first take-up shaft 1 and the second take-up shaft 2 with the same structure are rotated by the take-up motor and revolve around the same circle 7 .

[0029] Each of the two ends of the first coiling shaft 1 and the second coiling shaft 2 is movably connected with a connecting rod 8, and the bottom end of each connecting rod 8 is fixed on the rotating bracket 10 on the workbench 6, and the rotating bracket 10 is provided with a drive The first winding shaft 1 and the second winding shaft 2 are rotated along the circumference 7 by the turning motor, which is convenient for turning over the positions of the first winding shaft and the second winding shaft. Limit switches for controlling the revolution positions of the first win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com