Dynamic testing method for elevator's horizontally sliding door closing force

A horizontal sliding and dynamic testing technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of inaccuracy, low precision, unstable test data, etc., and achieve the effect of high test data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the invention will be further described below in conjunction with the accompanying drawings and examples.

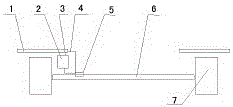

[0017] exist Figure 1 In the embodiment, the force receiver 4 is placed in the running track of the elevator door 1. During the door closing process, the elevator door will pass the closing pressure to the information processor through the pressure sensor 3, and the force receiver will also pass the speed through the speed sensor. 5 Pass the speed information to the information processor. The signal processor 2 calculates the required data through conversion.

[0018] The speed calculation value is calculated according to the following formula.

[0019] F(i)=15kF i v i (N)-----(1).

[0020] In the formula, F(i)----calculated value of door closing resistance (N).

[0021] f i ----Test regulation pressure (N), read directly from the sensor by the test.

[0022] v i ----The elevator door closing speed in the test (m / s).

[0023] v i =dl / dt(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com