Knapsack-type electric atomizing sprayer for plant protection

A knapsack and mist misting machine technology, which is applied to the application, device for capturing or killing insects, animal husbandry, etc., can solve the problems of low processing precision, large amount of spraying liquid, and low operating efficiency, and achieve a high degree of automation , low labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

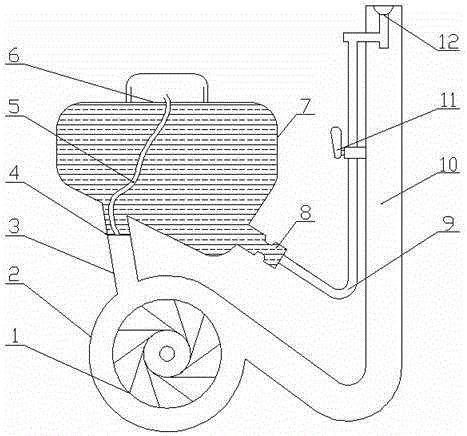

[0016] Such as figure 1 As shown, a backpack electric mist machine for plant protection includes an impeller 1, a liquid medicine tank 7 and a nozzle 12, and the fan housing 2 is provided with an impeller 1, which generates a high-speed airflow through its own high-speed rotation. An air outlet pipe 3 is arranged on the fan housing 2, and the air outlet pipe 3 is used to transport the high-speed airflow generated by the impeller. An air inlet plug 4 is arranged inside the air outlet pipe 3, and a liquid medicine tank 7 is arranged above the air outlet pipe 3. Liquid medicine tank 7 is used for storing liquid medicine, and liquid medicine box 7 is provided with filter screen 6, and filter screen 6 is used for filtering the impurity in the airflow, is connected with intake pipe 5 between air inlet plug 4 and filter screen 6, and liquid medicine A liquid outlet plug 8 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com