Ultra-low humidity and low temperature wind inlet smashing equipment

A crushing equipment and low-temperature technology, which is applied in the field of ultra-low humidity and low-temperature air-inlet crushing equipment, can solve problems such as local temperature rise, material changes, and adhesion, and achieve the effects of reducing heat-sensitive material denaturation, reducing working pressure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

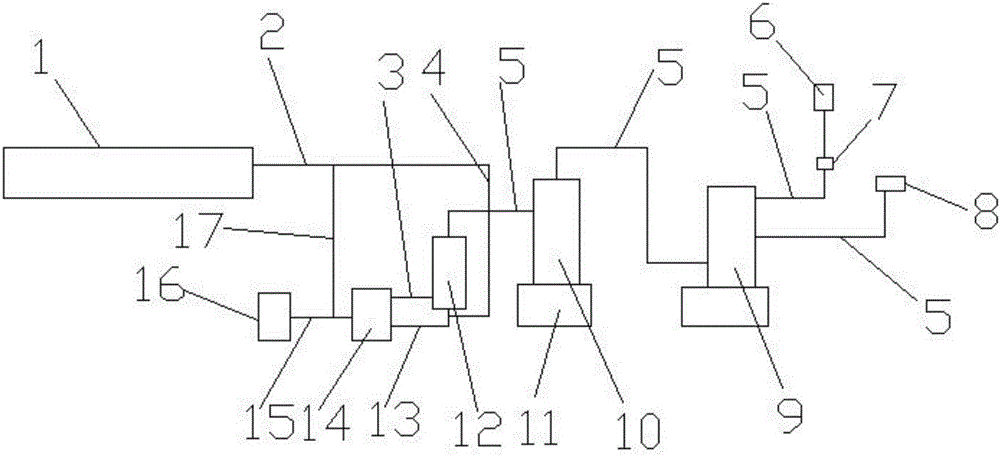

[0019] Embodiment 1. An ultra-low humidity and low-temperature air inlet crushing equipment, comprising: an air treatment system 1, a first air guide pipe 2, a first material pipe 3, a second air guide pipe 4, a second material pipe 5, a muffler 6, an air guide Fan 7, oil-free air compressor 8, isolation collector 9, cyclone collector 10, receiving barrel 11, classifier 12, third material pipe 13, general-purpose pulverizer 14, fourth material pipe 15, feeding system 16. The third air duct 17; wherein: one end of the air handling system 1 is provided with a first air duct 2; one side of the first air duct 2 is connected to the fourth material pipe 15 through the third air duct 17; the first air duct One side of 2 is connected to the third material pipe 13 through the second air guide pipe 4; the feeding system 16 is connected to the general-purpose pulverizer 14 through the fourth material pipe 15; the general-purpose pulverizer 14 is connected to the classifier through the fir...

Embodiment 2

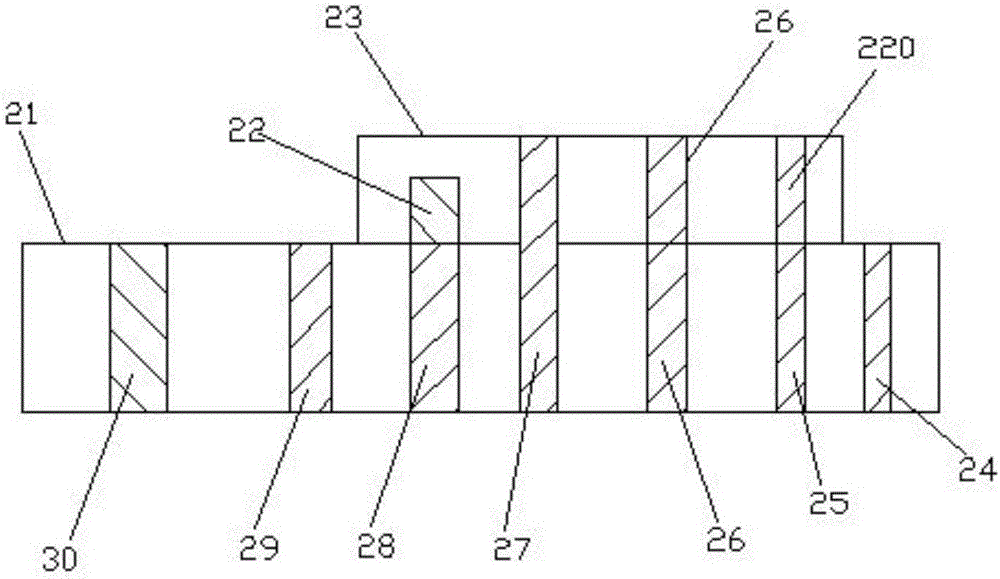

[0020] Embodiment 2. An ultra-low humidity and low temperature air intake crushing equipment, wherein: the air treatment system 1 is composed of a first ventilation duct 21, an exhaust fan 22, a second ventilation duct 23, an air supply fan 24, a high-efficiency filter section 25, and a heating section 26. The runner dehumidification section 27, the surface cooling section 28, the medium-efficiency filter section 29, the primary-effect filter section 30, and the primary and medium-efficiency filter section 220; the upper end surface of the first ventilation pipe 21 is placed with a second ventilation pipe 23;

[0021] The inside of the first ventilation duct 21 is provided with a blower fan 24, a high-efficiency filter section 25, a heating section 26, a runner dehumidification section 27, a surface cooling section 28, a medium-efficiency filter section 29, and an initial-effect filter section 30 from right to left. The inside of the second ventilation duct 23 is provided with ...

Embodiment 3

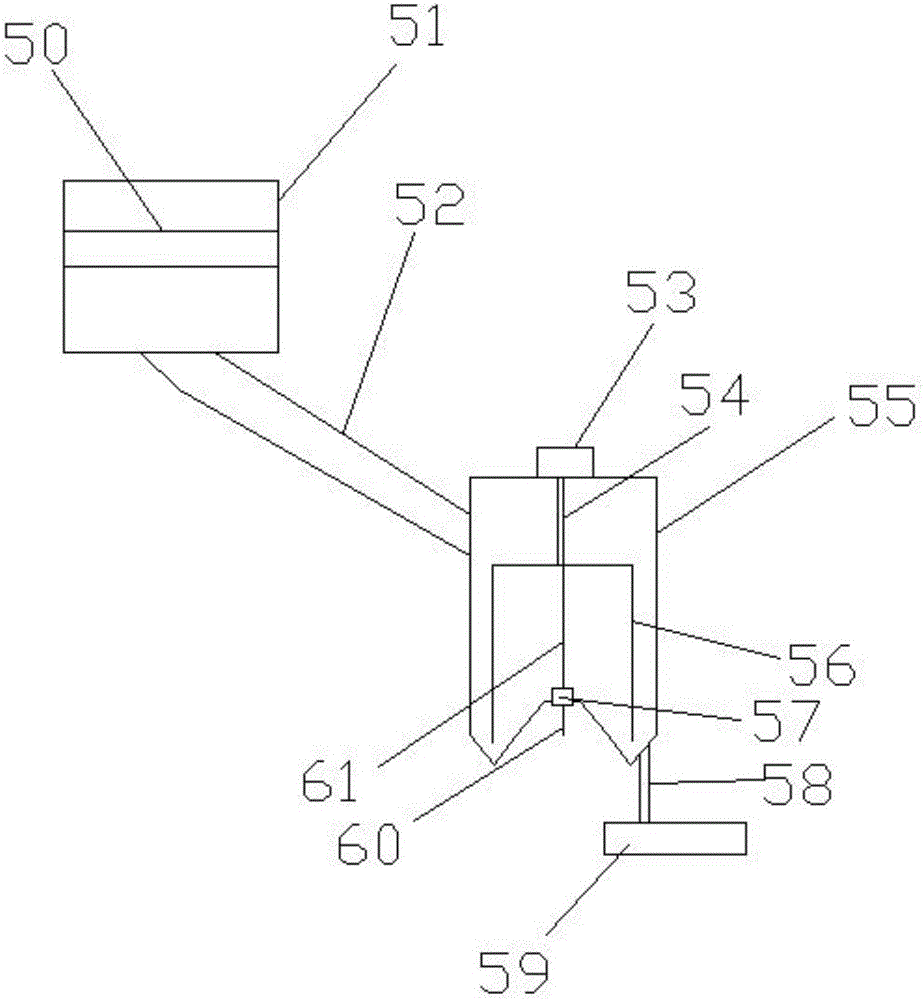

[0022] Embodiment 3, an ultra-low humidity and low temperature air intake crushing equipment, wherein: the feeding system 16 is composed of a primary pulverizer 50, a feeding hopper 51, a mixer 55, and a feeding machine 59; the feeding hopper 51 passes through the feed pipe 52 and The stirrer 55 communicates; the outside of the stirrer 55 is provided with a stirring motor 53; one end of the stirring shaft 54 is placed in the stirring machine 55 and is connected with the stirring fin 56; the other end of the stirring shaft 54 passes through the shell of the stirring machine 55 and links to each other with the stirring motor 53; The inside of the stirring fin 56 is hollow, and the outer wall is provided with evenly distributed through holes; one end of the air guiding steel pipe 61 is connected to the stirring fin 56; The bottom of mixer 55 links to each other with feeder 59 by connecting pipe 58; Feed hopper 51 inside is provided with pulverizer 50 for the first time; A sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com