A multi-station assembly screwing device for a smoke alarm

A smoke alarm and multi-station technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems that manual screwing cannot ensure accurate pressure, increase product manufacturing costs, and unstable product quality. Ingenious, reduced labor costs, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

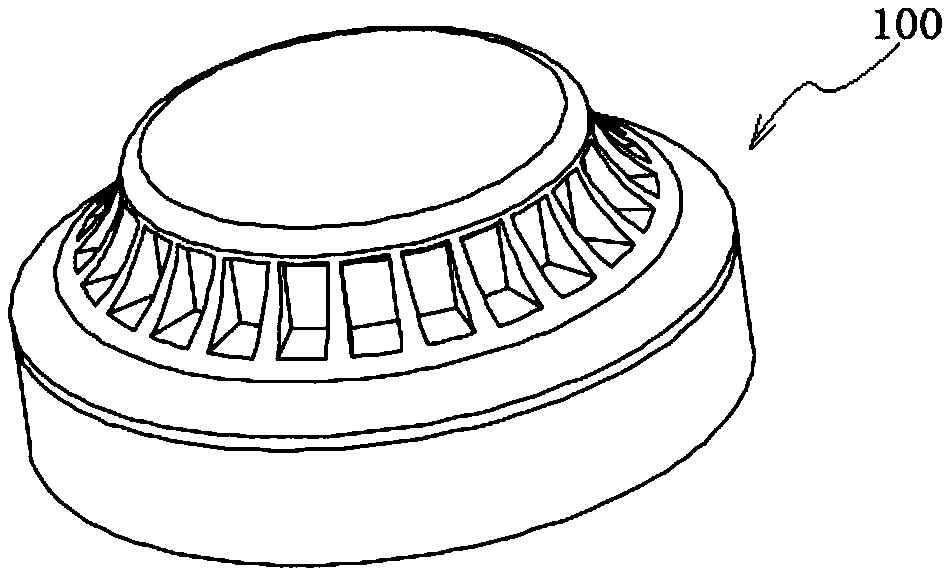

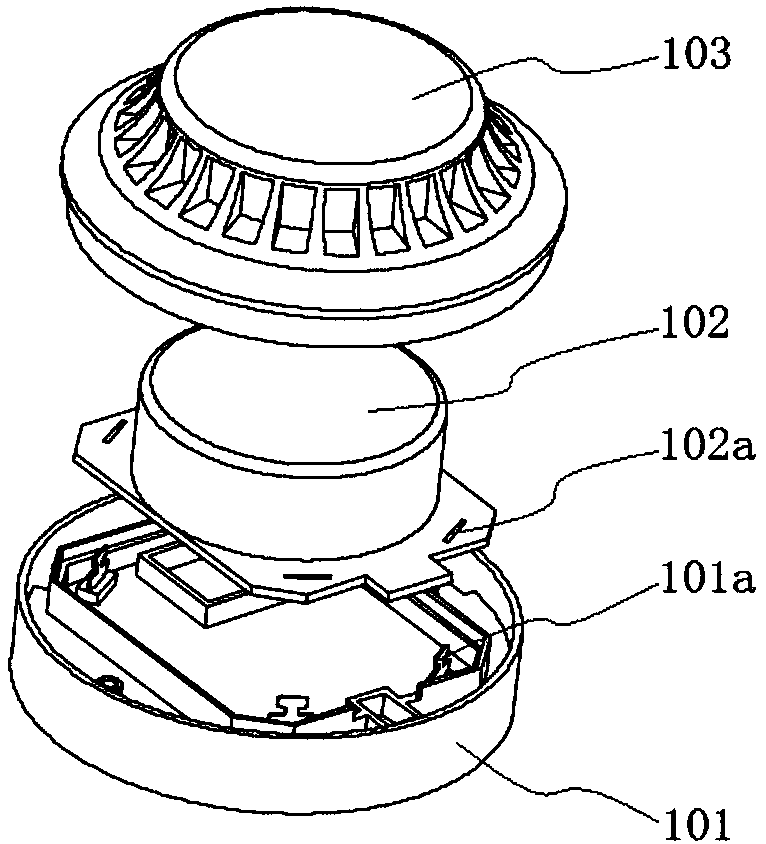

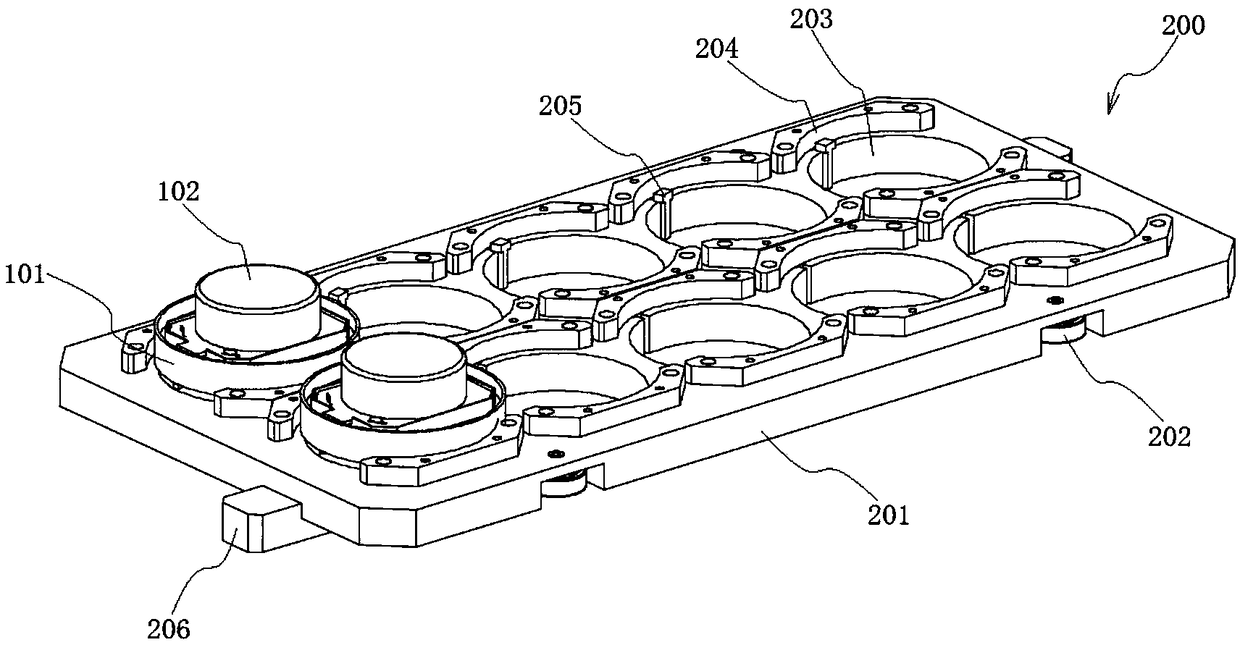

[0046] combine Figure 4 with Figure 5 As shown, a smoke alarm multi-station assembly screwing device of this embodiment includes a frame 1, a jacking mechanism 2 arranged at the bottom of the frame 1 and a foot screwing mechanism 3 arranged at the top of the frame 1. The foot screwing device can be used in conjunction with the smoke alarm assembly production line, and the assembled base 101 and integrated circuit element 102 are arranged in such as image 3 The positioning pallet 200 shown is transported to the top of the jacking mechanism 2 by the conveying mechanism. The positioning pallet 200 includes a pallet body 201, and rollers 202 are provided on both sides of the pallet body 201 to facilitate the movement of the positioning pallet 200. , the pallet body 201 is provided with a number of through holes 203, and a contour positioning block 204 is arranged around each through hole 203 for positioning the base 101 of the smoke alarm, and an angle is provided on the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com