A blast furnace taphole top suction dust removal device

A dust removal device and blast furnace iron tapping technology, applied in dust collectors and other directions, can solve problems such as weak collection capacity and poor working environment in the casthouse, and achieve super large collection capacity, little impact on equipment maintenance, and good maintenance convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

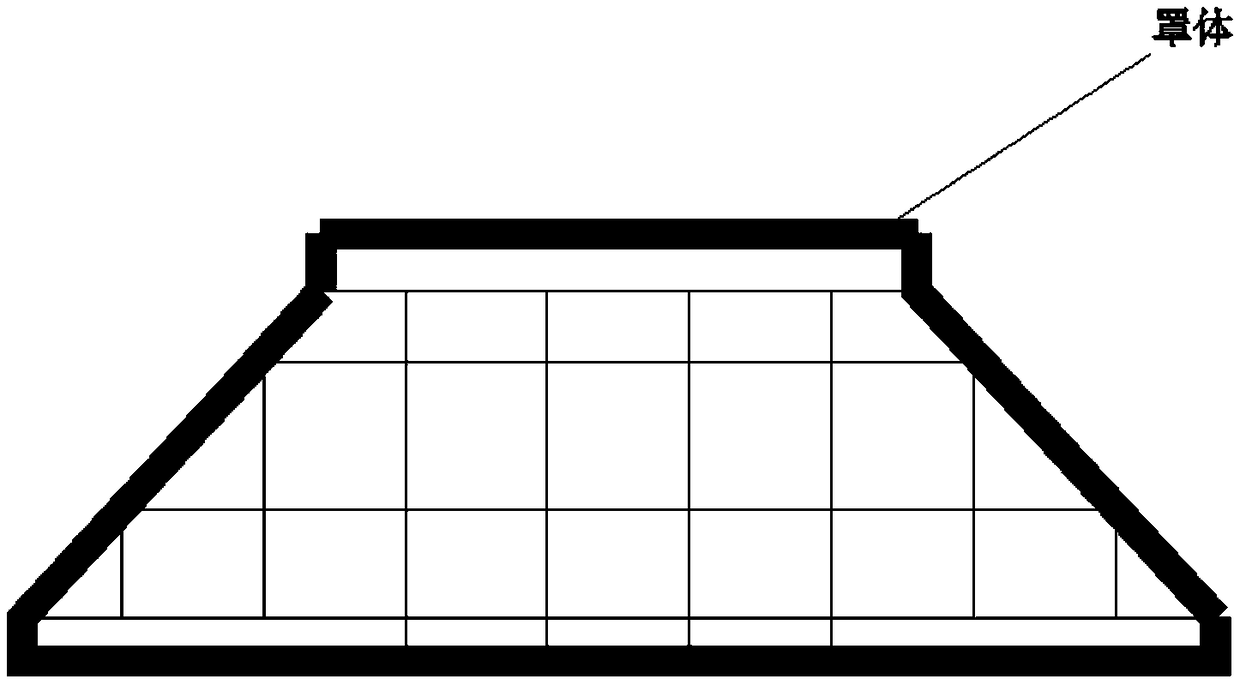

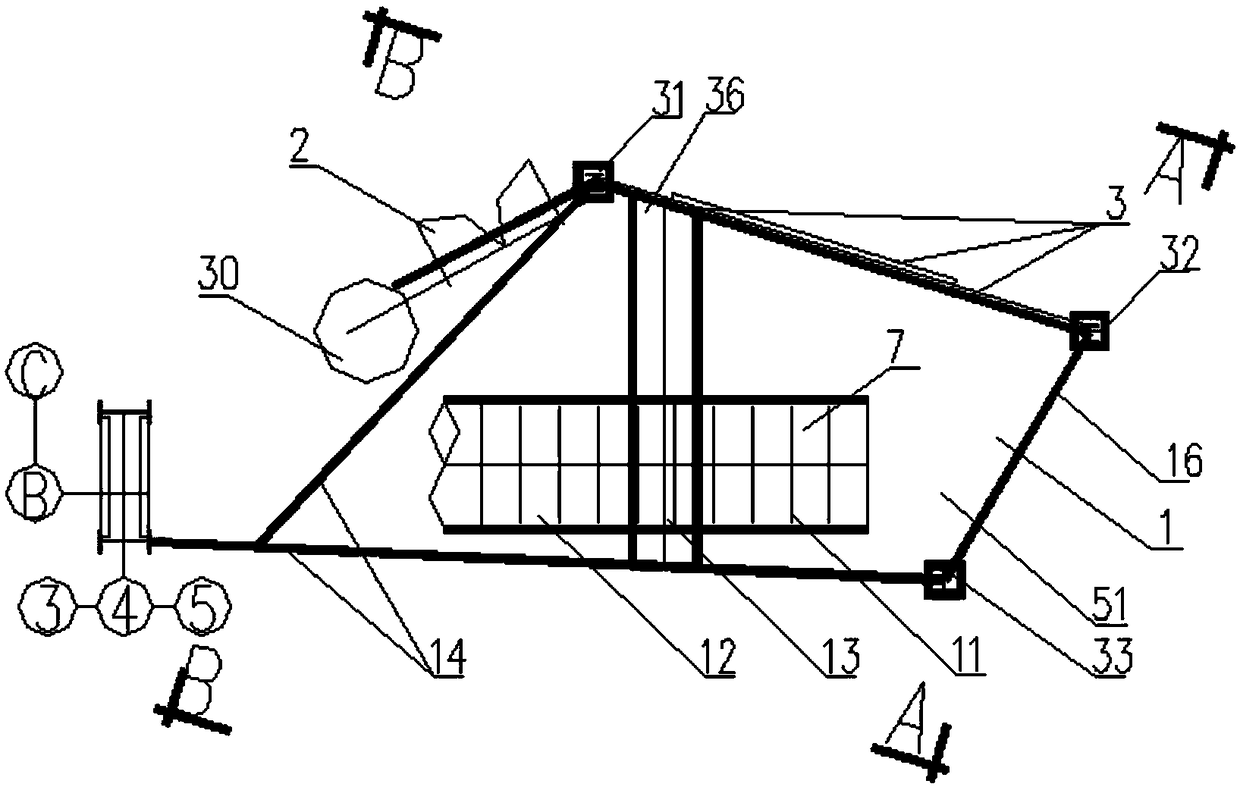

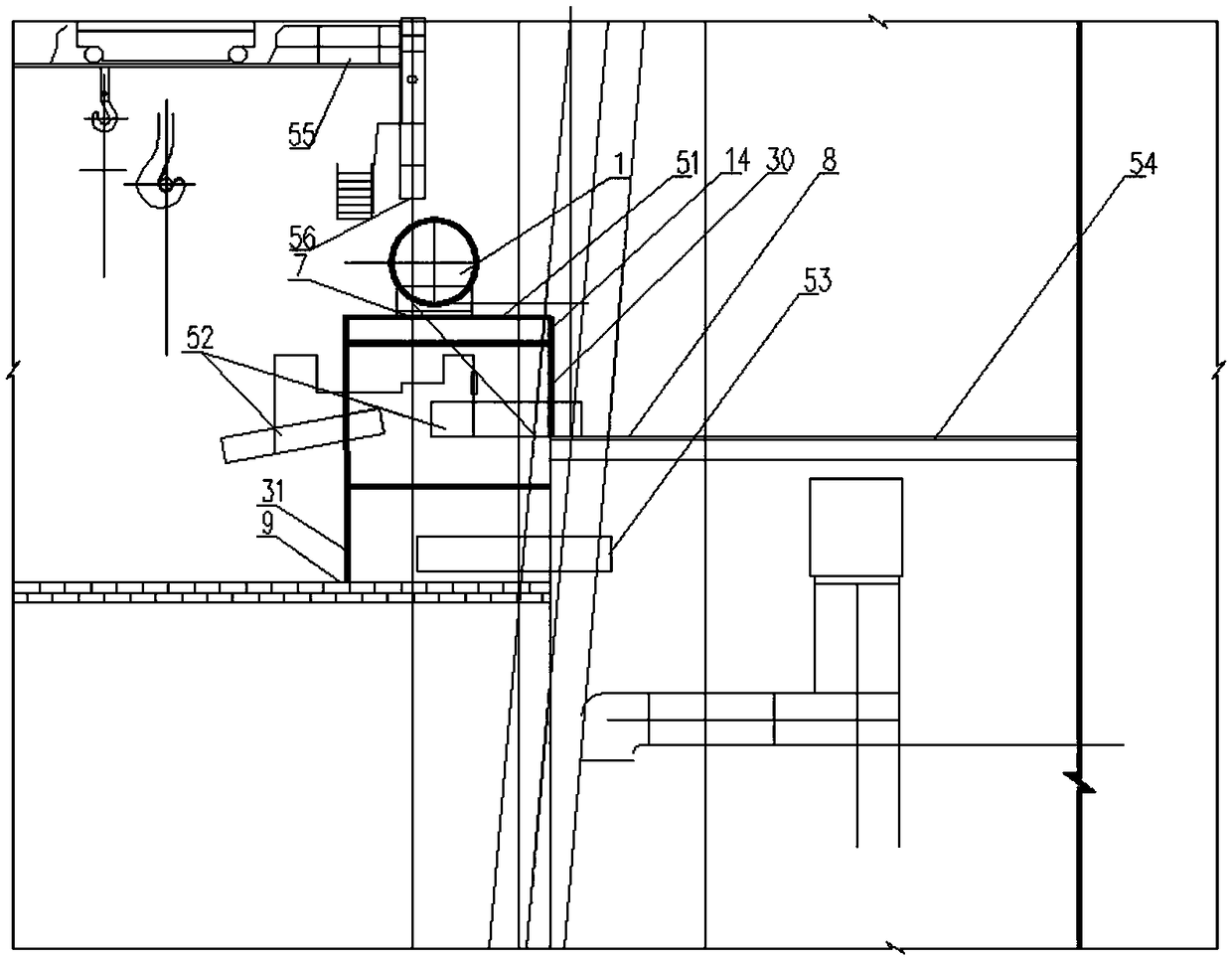

[0066] In this embodiment, if figure 2 As shown, above the high tuyere platform 8 is provided with a blast furnace mud operation door 2 between the blast furnace frame column 30 and the high tuyere platform column 31, the high tuyere platform is provided with an additional iron ditch above the tuyere operation door 3, and the low position The casthouse platform is provided with a low-level casthouse platform column 33 and its transverse wind retaining wall 16, and the top suction and dust removal device on the elevated opening machine 52 side. Double doors, the structure of the double doors is as follows:

[0067] Including door frame, door handle, side-by-side double doors, door latches and door hinges, wherein: side-by-side double doors are symmetrically fixed on both sides of the door frame with one left and one right; The high position tuyere platform 8 is a steel structure platform covered with refractory bricks. The low casthouse platform 9 is a reinforced concrete st...

Embodiment 2

[0074] The scheme of this embodiment is as follows: the whole device also includes a high-position tuyere platform above which is provided with a tuyere operation door 3 above the iron ditch, and the tuyere operation door 3 is a double-track three-leaf rectangular door; the tuyere operation door 2 includes a door frame, a door handle, an upper The suspension mechanism, the lower pulley and the upper convex track; the two pulleys are fixedly connected through the wheel shaft to form an integrated tuyere operation door; the upper convex track is fixed on the bottom beam above the high-level tuyere platform.

[0075]When the tuyere of the blast furnace is blocked near the operation door 3 of the tuyere, safety measures should be strictly followed. First, wear protective masks, earplugs and other labor protection supplies, and use a gas alarm to measure the gas in the area around the tuyere to meet the allowable gas concentration. After the conditions are met, use the door handle t...

Embodiment 3

[0078] Its basic structure is the same as that of Embodiment 1, and the improvement is that: redesign the air suction port 7 on the top of the flat cover, and under the condition that the large-area three-section pipe cover ring beam 14 remains unchanged, it can be lifted for the mud gun machine and its support. Reserve the movable cover plate 36 on the top of the mud gun machine and its supporting maintenance channel, and split the air suction port 7 on the top of the flat cover and the upper three-section dust collection cover 1 into three sections; that is, the mud gun machine and its supporting maintenance channel end section There are three parts: pipe cover 11, mud gun machine and its support and maintenance channel front section pipe cover 12 and mud gun machine and its support and maintenance channel pipe cover 13. The mud gun machine and its support and maintenance channel pipe cover 13 are detachable. All are supplemented with external ribs to meet the rigidity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com