Dust backpressure explosive-proof valve

A back pressure, explosion-proof technology, applied in the direction of control valve, safety valve, balance valve, etc., can solve problems such as power explosion, and achieve the effect of increasing safety, improving effect, and reducing sealing prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

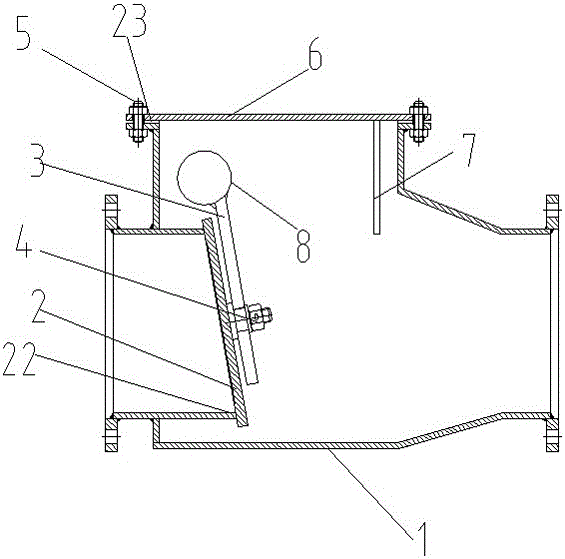

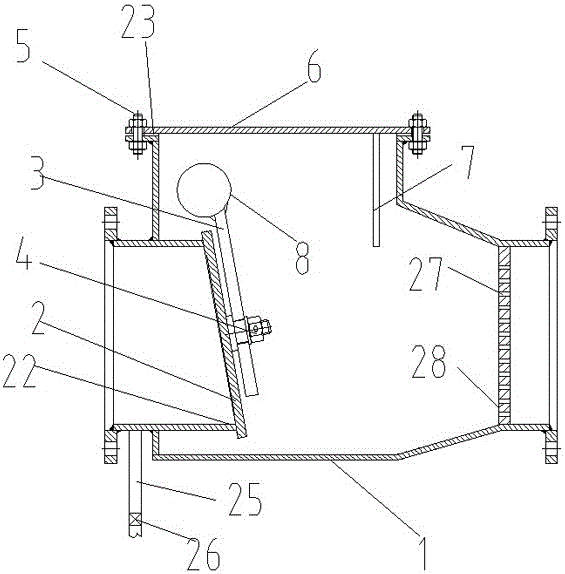

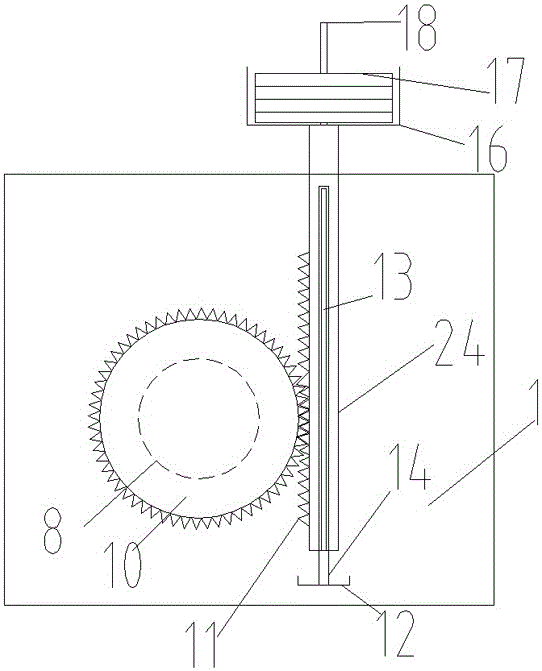

[0016] Such as figure 1 , 3 1. A dust back pressure explosion-proof valve shown in 4 includes a valve body 1 and a valve disc 2. The valve body 1 is integrally fixed with an inclined end face 22. The integral fixation has a better flameproof effect than other fixing methods. The valve disc 2 Matched with the inclined end surface 22, the valve disc 2 can cover the inclined end surface 22. The valve disc 2 is fixedly connected with the valve disc rocker 3 through the first bolt 4. The upper end of the valve disc rocker 3 is fixed with a positioning shaft 8, and the positioning shaft 8 By rotating the rocker 3 to control the rotation of the disc rocker, at least one end of the positioning shaft 8 can be rotatably installed on the side of the valve body. After the contact end is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com