Combustor provided with integral fire cover

A kind of burner, integrated technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problem of weak flame heating, etc., achieve the effect of uniform combustion temperature field, enlarged heating range, and strong impact of viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

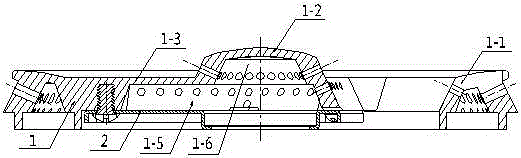

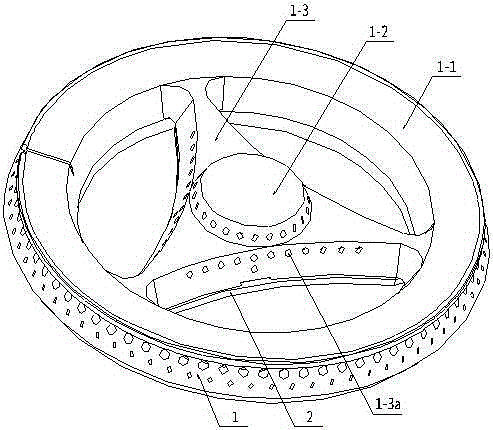

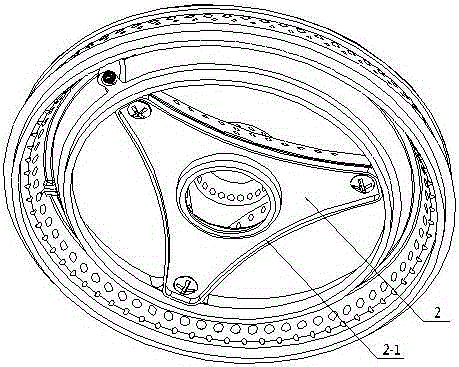

[0029] A burner equipped with an integral fire cover at least includes a burner main body and a large and small fire cover. The integral fire cover at least includes a fire cover main body 1 and a fire cover seat 2. The fire cover main body includes Between the large fire cover 1-1 and the small fire cover 1-2, there are three spokes 1-3, which connect the large and small fire covers as a whole. -6 connected cavities 1-5, the spokes are provided with several fire holes 1-3a to communicate with the cavity; the main body of the fire cover is provided with a fire cover seat mounting surface 1-4, and 3 threaded mounting surfaces are provided. Hole 1-4a, the central part of the fire cover seat is provided with an opening, and the periphery is provided with 3 mounting holes, and the fire cover seat and the fire cover body are connected as a whole through a threaded connection structure;

[0030] The spokes on the main body of the fire cover in this embodiment have a small outer end ...

Embodiment 2

[0033] Such as Figure 7-8 As shown, the only difference between this embodiment and Embodiment 1 is that the top surface of the spokes on the main body of the fire cover is flush with the top surface of the fire cover.

Embodiment 3

[0035] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the outer end of the spokes on the main body of the fire cover is placed on the top surface of the large fire cover, the top of the small fire cover is arc-shaped, and the installation surface of the fire cover seat on the fire cover main body is in line with the implementation The shape of example 1 is somewhat different, and the shape of the fire cover seat also changes thereupon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com