A method for performance evaluation of catalysts for propane dehydrogenation to propylene

A propane dehydrogenation and catalyst technology is applied in the field of chemical experiments, which can solve the problems that the catalytic reaction cannot be continuous, affect the experimental efficiency and results, and affect the reaction results, etc., so as to achieve good use effect, save test time, and improve activity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

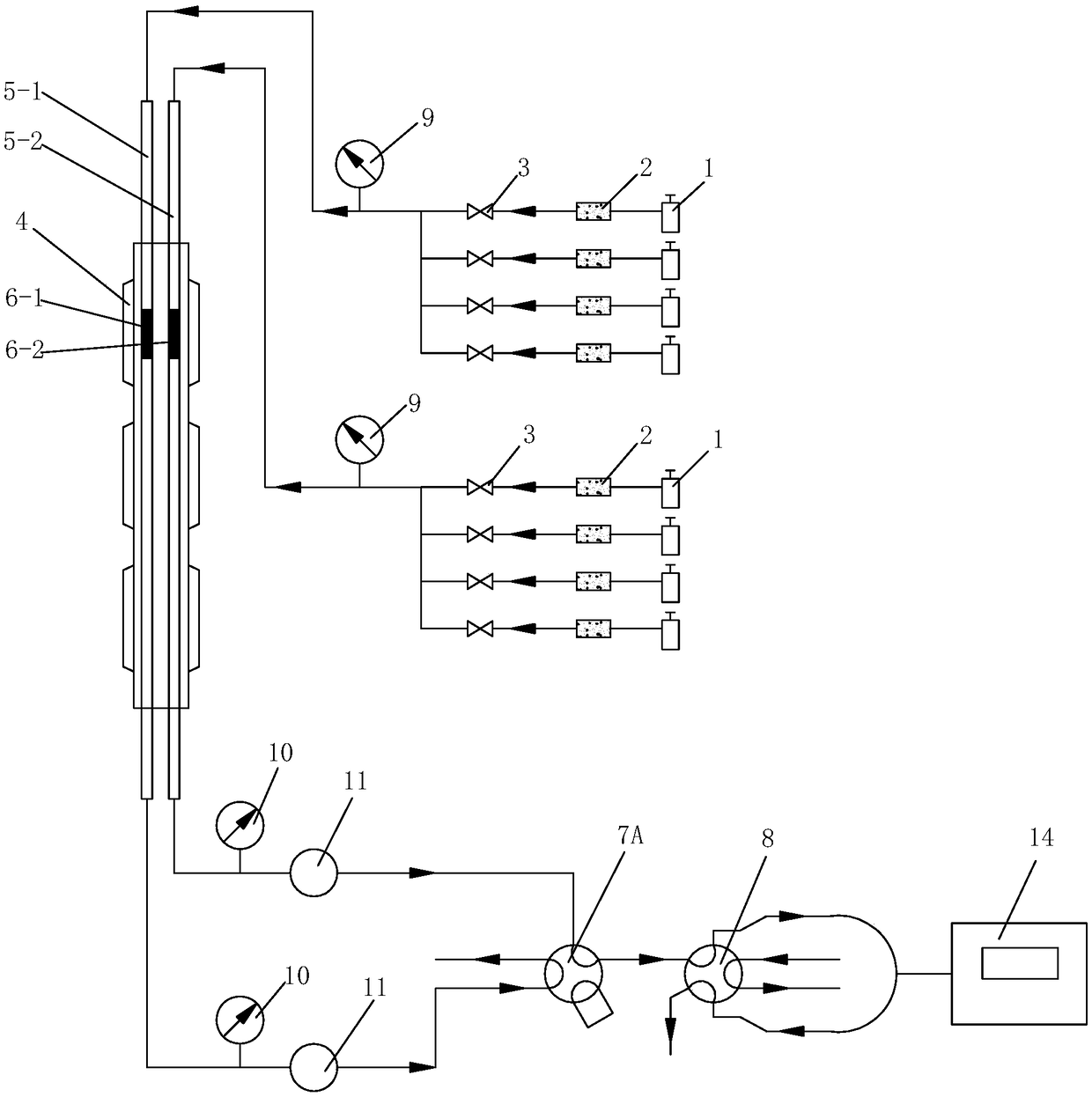

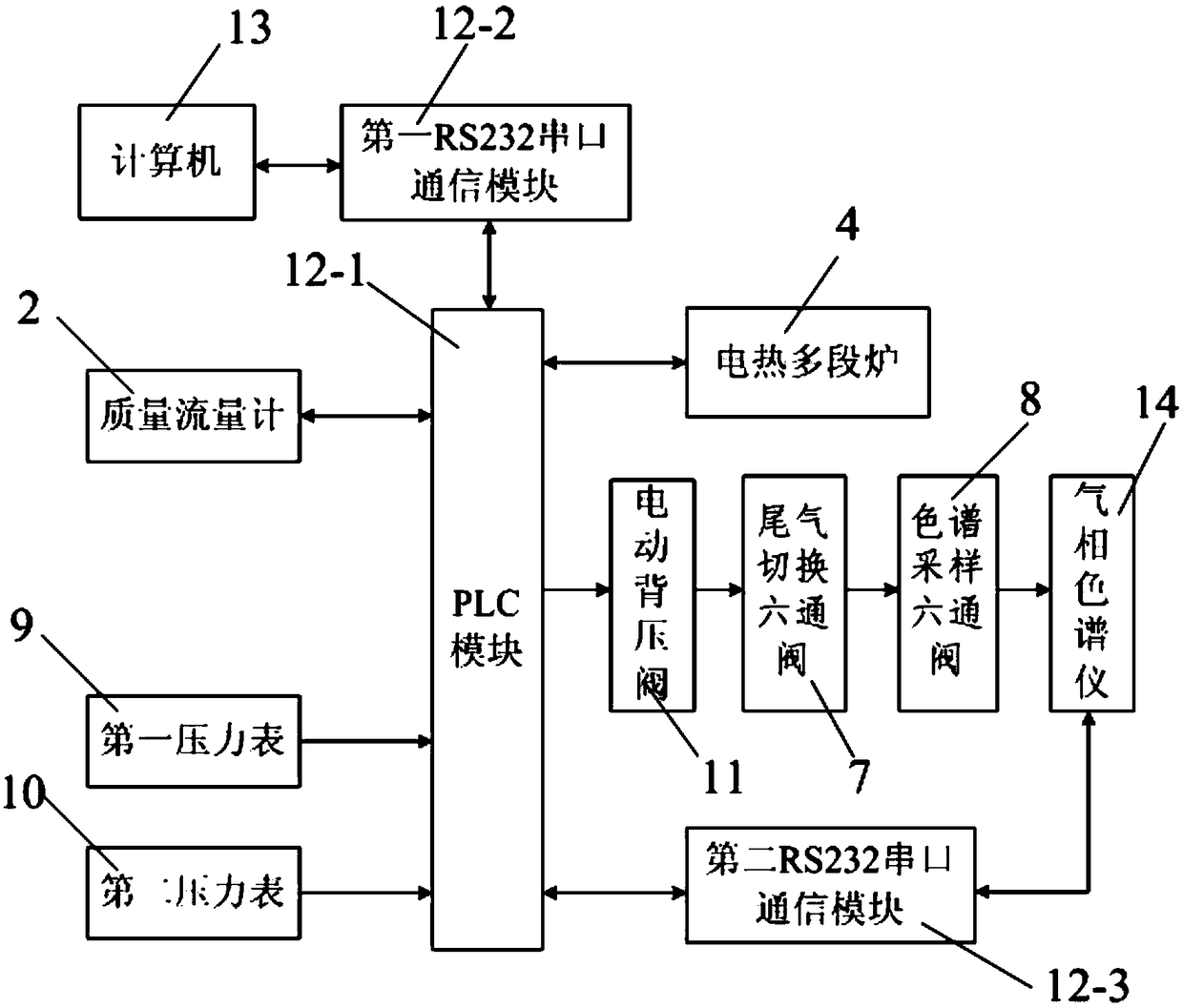

[0055] like figure 1 and image 3 As shown, the performance evaluation device of the catalyst for propane dehydrogenation to propylene in this embodiment includes: a computer control part, a gas path part, a reaction part connected to the gas path part, and an analysis and detection part connected to the reaction part;

[0056] The gas circuit part includes four gas pipelines connected in parallel, the four gas pipelines are nitrogen pipeline, propane pipeline, hydrogen pipeline and air pipeline respectively, and each gas pipeline is provided with a gas pipeline connected in series. Bottle 1, mass flow meter 2 and check valve 3;

[0057] The reaction part includes an electrothermal multi-stage furnace 4 with a high temperature section, a medium temperature section and a low temperature section. A reaction tube is inserted through the electrothermal multi-stage furnace 4, and an inlet pressure gauge 9 is arranged at the entrance of the reaction tube. , the outlet of the react...

Embodiment 2

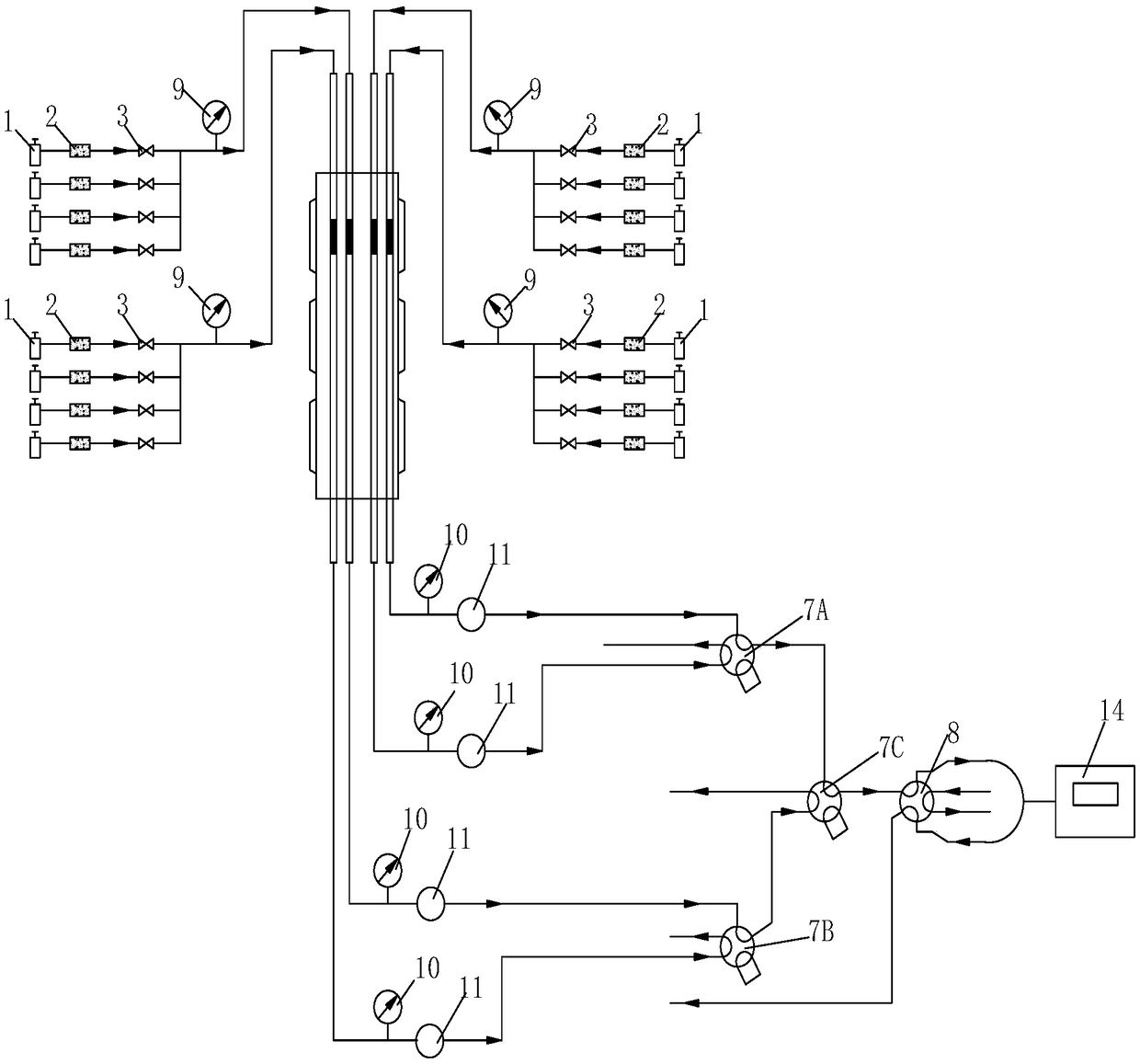

[0065] like figure 2 and image 3 As shown, the performance evaluation device of the catalyst for propane dehydrogenation to propylene in this embodiment includes: a computer control part, a gas path part, a reaction part connected to the gas path part, and an analysis and detection part connected to the reaction part;

[0066] The gas circuit part includes four gas pipelines connected in parallel, the four gas pipelines are nitrogen pipeline, propane pipeline, hydrogen pipeline and air pipeline respectively, and each gas pipeline is provided with a gas pipeline connected in series. Bottle 1, mass flow meter 2 and check valve 3;

[0067] The reaction part includes an electrothermal multi-stage furnace 4 with a high temperature section, a medium temperature section and a low temperature section. A reaction tube is inserted through the electrothermal multi-stage furnace 4, and an inlet pressure gauge 9 is arranged at the entrance of the reaction tube. , the outlet of the reac...

Embodiment 3

[0076] The present embodiment utilizes the method for evaluating the performance of the catalyst for propane dehydrogenation to propylene using the device described in Example 1 to include two stages, the first stage is to evaluate the performance of the active catalyst (i.e. method I); the second stage is When the activity of the active catalyst is reduced or deactivated due to long-term use, carbon deposition and other factors, the catalyst is regenerated, and the performance of the regenerated catalyst is evaluated (ie method II). combine figure 1 and image 3 , the present embodiment catalyst performance evaluation method specifically comprises the following steps:

[0077] The first stage is to evaluate the performance of the active catalyst. The specific process is:

[0078] Step 1. Pretreatment: Fill the reaction tube with an active catalyst for propane dehydrogenation to propylene, then insert the reaction tube into the electric heating multi-stage furnace 4, and place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com