Position fine-tuning structure of hall component of brushless DC motor

A brushless DC motor and component technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as unusable, alignment, and motor failure to achieve optimal performance, so as to improve the pass rate and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

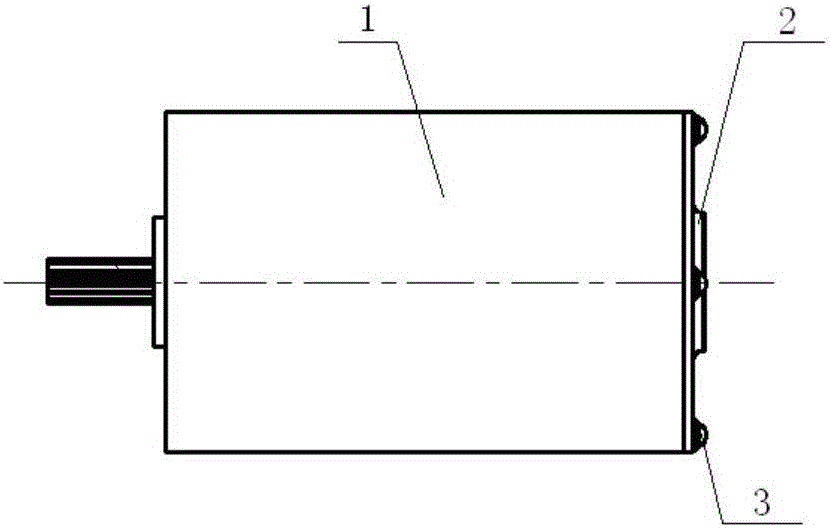

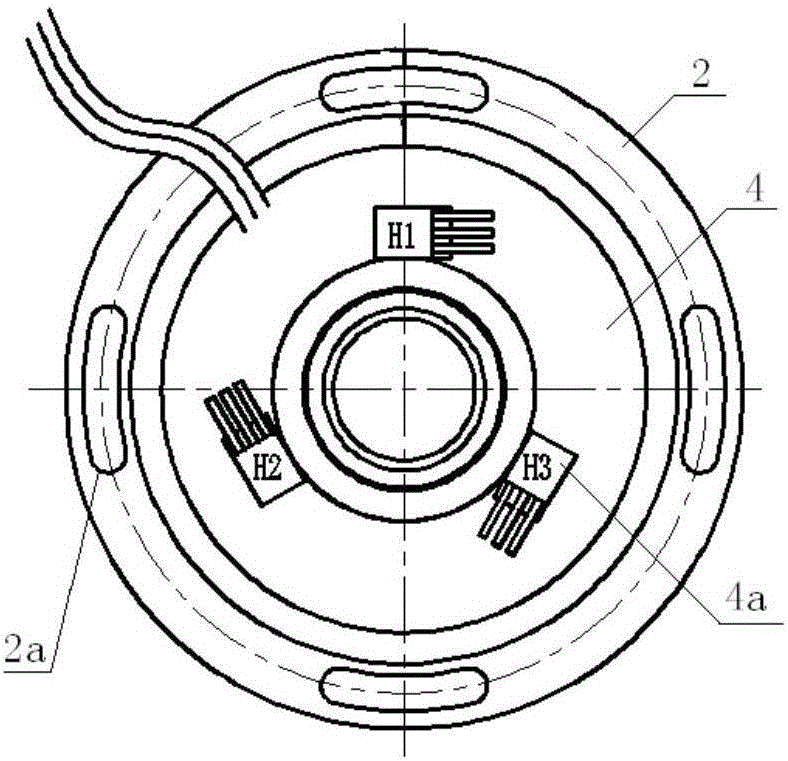

[0009] The present invention will be described in further detail below. see Figure 1 to Figure 3 , a fine-tuning structure for the position of the DC brushless motor Hall component, including a motor housing 1, a rear end cover 2 and a screw 3, and there are four screw holes evenly distributed along the circumference at the position of the rear end cover 2 close to the outer circumference , the rear end cover 2 is fixed on the rear end surface of the motor housing 1 by four screws 3, the Hall circuit board 4 is fixed on the inner surface of the rear end cover 2, and there are three on the Hall circuit board 4 Hall element 4a; characterized in that: the screw hole is an arc-shaped oblong hole 2a.

[0010] The working principle of the present invention is: use the motor power supply test box to supply power to the motor, the motor casing is basically aligned with the engraved line of the rear cover, measure the motor current, and then slightly rotate the rear end cover 2 to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com