Test method for front-sounding loudspeaker and system of test method

A test method and test system technology, applied in the direction of electrical components, can solve problems such as unsatisfactory results, waste of time and materials, and high investment costs, so as to improve research and development efficiency, reduce research and development costs, and improve customer experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

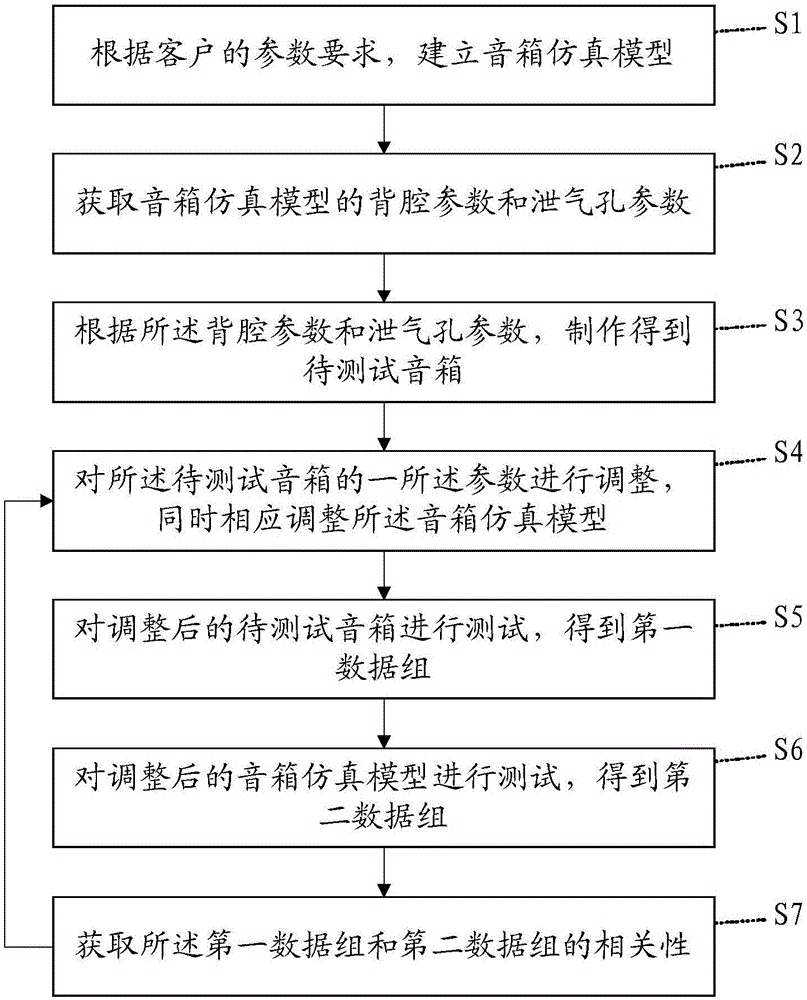

[0076] Please refer to figure 1 , Embodiment one of the present invention is: a kind of testing method of loud speaker, comprises the following steps:

[0077] S1: Establish a speaker simulation model according to the customer's parameter requirements; further, according to the external dimensions and functional requirements of the speaker product provided by the customer, such as the acoustic parameter requirements, the simulation engineer performs simulation calculations to establish a speaker simulation model, but due to the differences between the simulation data and There will be some differences in the real data, therefore, the establishment of the simulation model is to provide the production direction of the actual product.

[0078] S2: Obtain back cavity parameters and vent hole parameters of the sound box simulation model, the back cavity parameters include the total volume of the back cavity and the volume ratio and shape of each back cavity, and the vent hole param...

Embodiment 2

[0088] This embodiment is a specific application scenario of the foregoing embodiments.

[0089] Suppose the customer's requirement for THD is:

[0090] Test signal: sweep 100Hz~20kHz, 1 / 12 multiplier, sine wave calculation method between rated power: IEC standard, 2nd to 5th harmonic distortion.

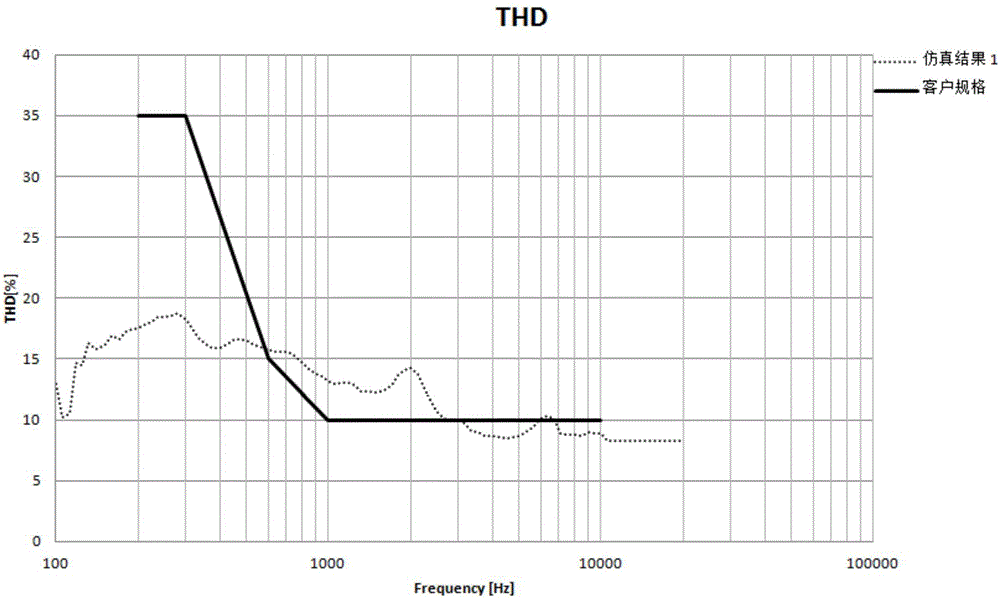

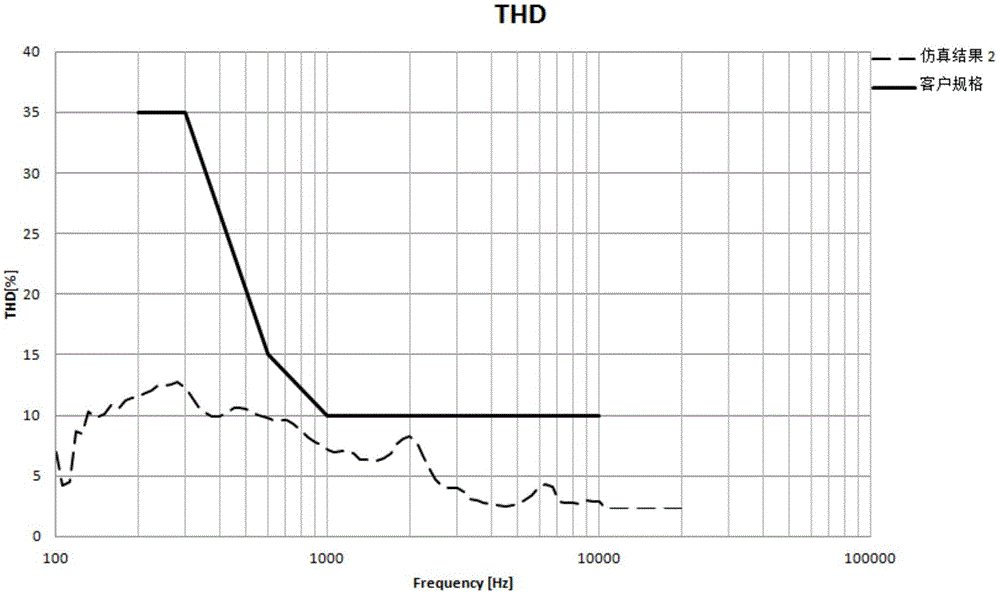

[0091] Carry out the first simulation completely according to the internal back cavity parameters given by the customer. The test results are as follows: figure 2 As shown, the solid line is the upper limit of the customer's requirement. It can be seen that most of the THD of the product exceeds the upper limit of the customer's requirement after 450HZ. This may be due to the wrong selection of the internal monomer of the speaker, or the internal cavity of the product. Adjust division, after eliminating the former possibility by verification, adjust the number of cavities (increase or decrease) and channel shape size (channel length and depth); for example, in this embodiment, it ...

Embodiment 3

[0093] Please refer to Figure 9 , this embodiment is a test system corresponding to the above-mentioned embodiment, which is a positive speaker, including:

[0094] Establish module 1, which is used to establish a speaker simulation model according to the customer's parameter requirements;

[0095] The first acquisition module 2 is used to obtain the back cavity parameters and vent parameters of the sound box simulation model, the back cavity parameters include the total volume of the back cavity and the volume ratio and shape of each back cavity, and the vent hole parameters include deflation The location and shape of the holes;

[0096] The production module 3 is used to produce the speaker to be tested according to the parameters of the back cavity and the parameters of the vent hole;

[0097] An adjustment module 4, configured to adjust a parameter of the speaker to be tested, and adjust the simulation model of the speaker accordingly;

[0098] The first test module 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com