Single gas type hydraulic automobile bumper

A car bumper, a single-air technology, applied in the direction of the bumper, can solve the problems of car body and personnel damage, complex structure, long response time of impact force, etc., to slow down the instantaneous impact force, broad application prospects, and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

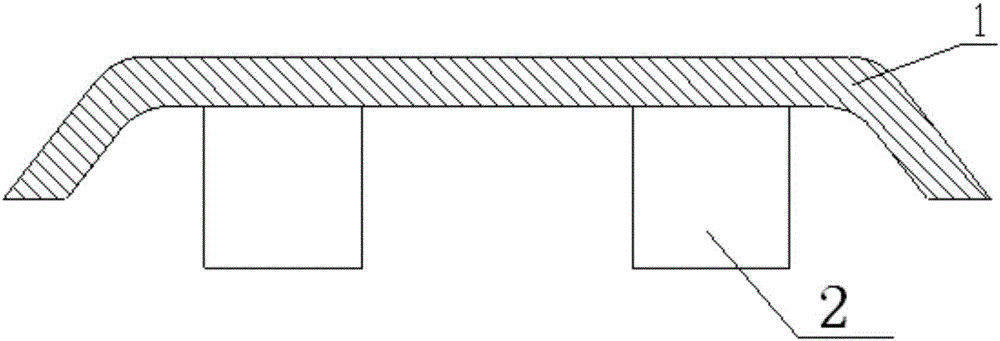

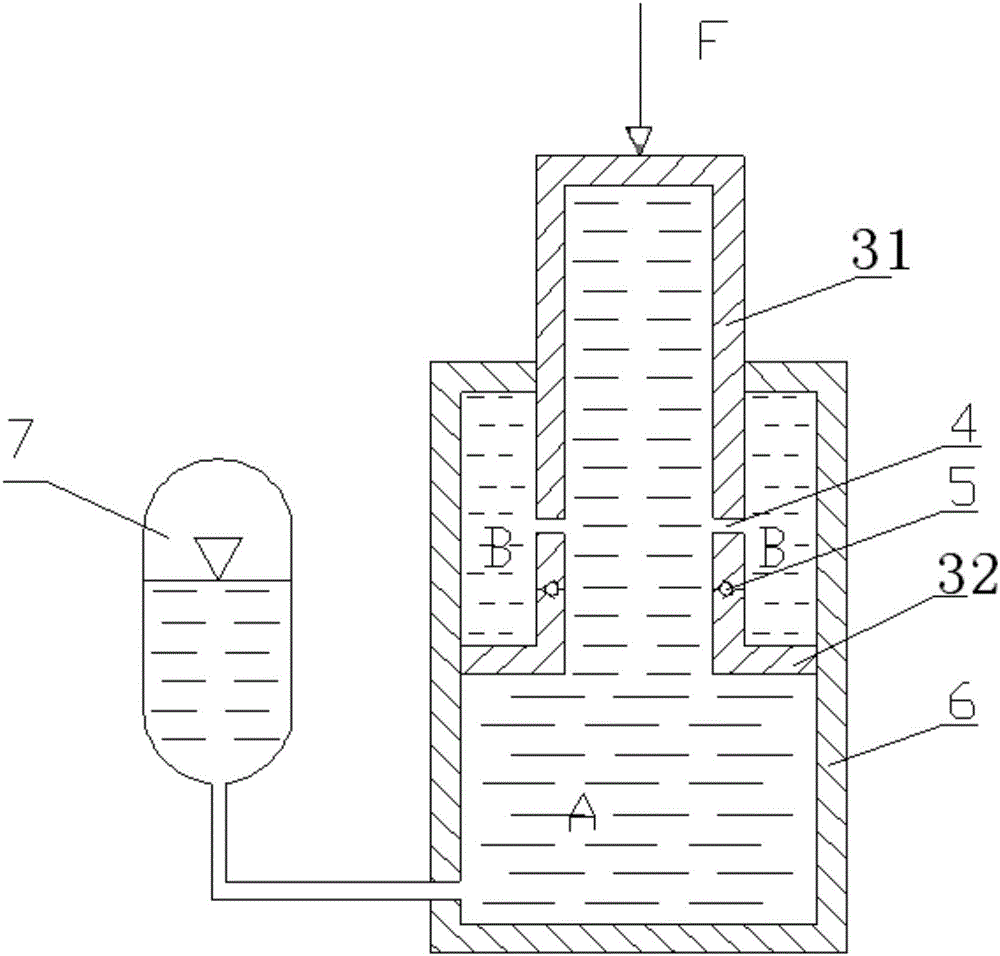

[0017] refer to figure 1 and figure 2 , the single-air hydraulic automobile bumper of the present invention comprises a bumper outer panel 1 and several single-air hydraulic buffer devices 2, and the single-air hydraulic buffer device 2 includes a piston 32, a piston rod 31, a cylinder 6 and The accumulator 7, the piston 32 is located in the cylinder 6, one end of the piston rod 31 is connected with the bumper outer panel 1, the other end of the piston rod 31 passes through the end of the cylinder 6 and is connected with the piston 32, the accumulator The oil port at the bottom of 7 communicates with the oil port at the bottom side of the cylinder 6 , the accumulator 7 and the cylinder 6 are filled with hydraulic oil, and the accumulator 7 is also filled with gas.

[0018] The piston 32 is an annular structure, the outer end surface of the piston 32 is in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com