Buffering semi-package structural body for household oil press equipment transportation

A technology of oil press and structure, which is applied in the field of cushioning semi-package structure for household oil press equipment transportation, which can solve the problems of single function, single form, damage, etc., to improve stability, facilitate die-cutting production, improve The effect of buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

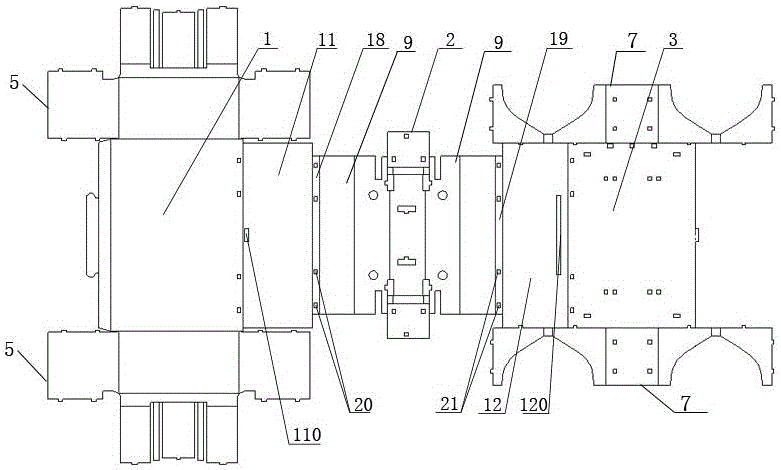

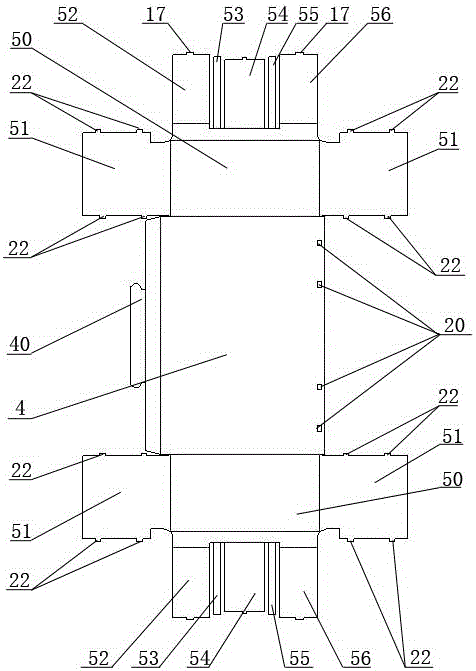

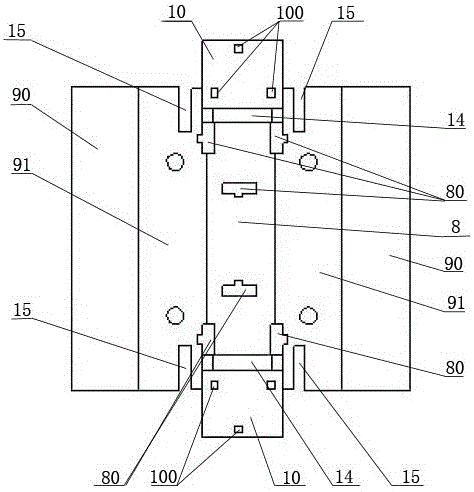

[0022] A buffer half-pack structure for household oil press equipment transportation. The buffer half-pack structure is folded from a piece of corrugated paper. It has a compact structure and is convenient for die-cutting production. occupancy of space. Its structure is as Figure 13 Shown; its expansion schematic diagram is shown in figure 1 As shown, the present invention includes an outer box body 1 , an inner liner body 2 and a support body 3 .

[0023] Such as figure 1 with figure 2 As shown, the outer box body 1 includes an outer plate 4 arranged at the bottom and two outer plates 5 symmetrically arranged on opposite sides of the outer plate 4. The first connection plate 11 is provided with a socket I1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com