Sandstone conveying apparatus

A conveying device, sand and gravel technology, applied in the field of construction machinery, can solve the problems of simple structure, single function, sand and gravel agglomeration, etc., to achieve the effect of reasonable structure, strong practicability and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

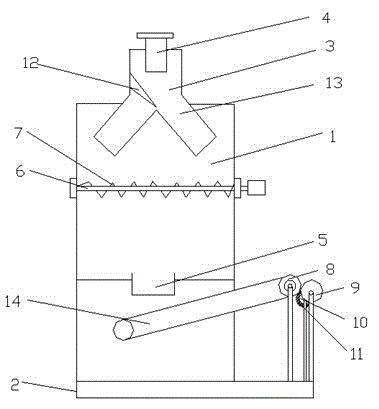

[0012] A sand and gravel conveying device of the present invention includes a hopper 1, a frame 2 supporting the hopper 1, and a crushing mechanism arranged in the frame 2. The hopper 1 is fixedly installed on the frame 2, and the upper part of the hopper 1 is provided with a distributor 3, and the lower part A discharge port 4 is provided. The top of the distributor 3 is provided with a feed port 5. The crushing mechanism includes a plurality of crushers arranged side by side inside the hopper 1. The crusher includes a rotating shaft 6 which penetrates through the two side walls of the hopper , The surface of the rotating shaft 6 is provided with a stirring blade 7, one end of the rotating shaft 7 is provided with a driving device, and a conveyor belt 14 is provided under the discharge port 4. The conveyor belt 14 surrounds the roller 8, and the roller 8 is driven by the friction transmission wheel 9. A cleaning device is provided between the friction transmission wheel 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com