Reel tool special for marine cable pre-cutting and slitting

A technology for marine cables and trays, which is applied in the field of special trays for pre-cutting and cutting marine cables. Long life ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

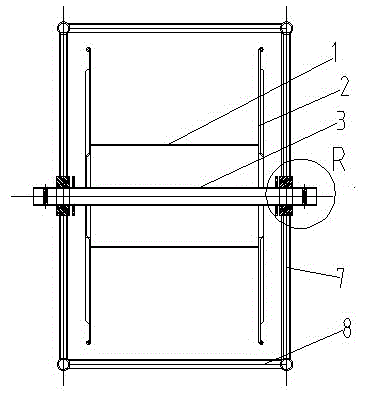

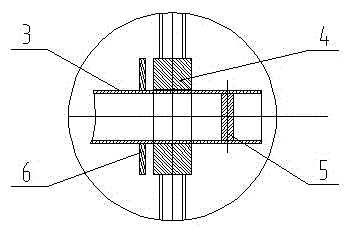

[0009] A special tray for pre-cutting and cutting of marine cables, the tray includes a cylinder body 1, a side plate 2, an outer retaining ring 7 and a crosspiece 8, and the side panels 2 are arranged on both sides of the cylinder body 1 to form an inner tray , the outer retaining ring 7 is arranged on both sides of the crosspiece 8 to form an outer disk, the inner disk and the outer disk are coaxially arranged, and the center axis of the inner disk and the outer disk is provided with a disk shaft 3, and the disk shaft 3 and the inner disk Fixedly connected, the center of the outer disk is provided with a support seat supporting the disk shaft 3, and the disk shaft 3 is provided with a plurality of baffles 6 to prevent the axial movement of the inner disk, and the baffles 6 are arranged on Between the outer retaining ring 7 and the side plate 2 , both ends of the dish shaft 3 protrude from the outer retaining ring 7 and are provided with pins 5 , and the pins 5 are perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com