Water and air discharging non-return valve

A non-return valve and non-return technology, applied in the direction of valve details, control valves, safety valves, etc., can solve problems such as endangering the ecological environment and sanitation, and achieve the effects of no loss of protection, convenient installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

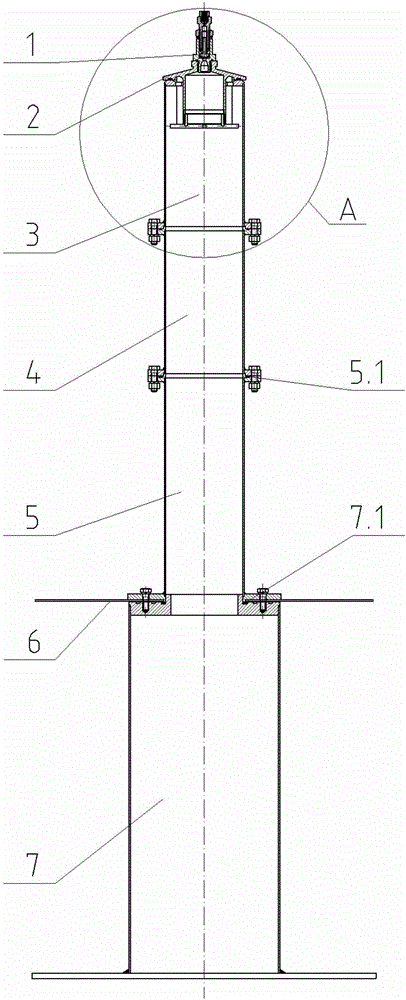

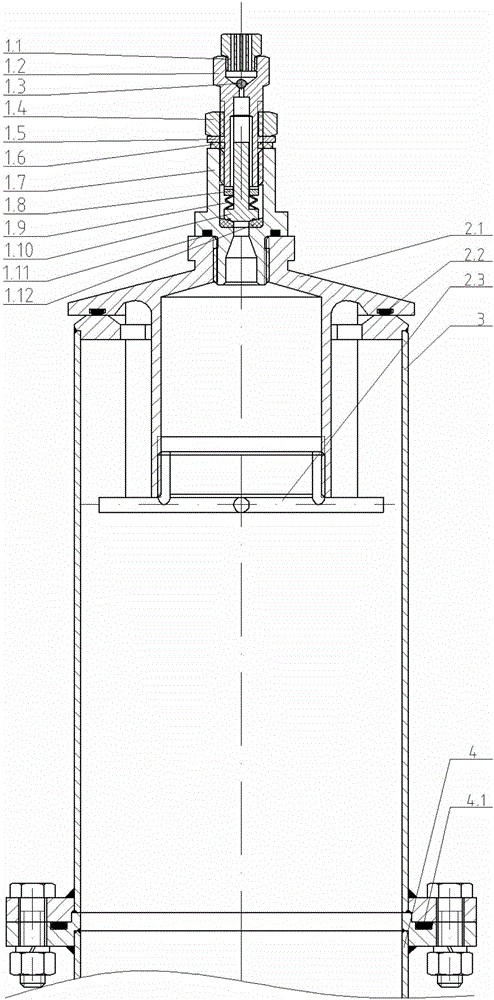

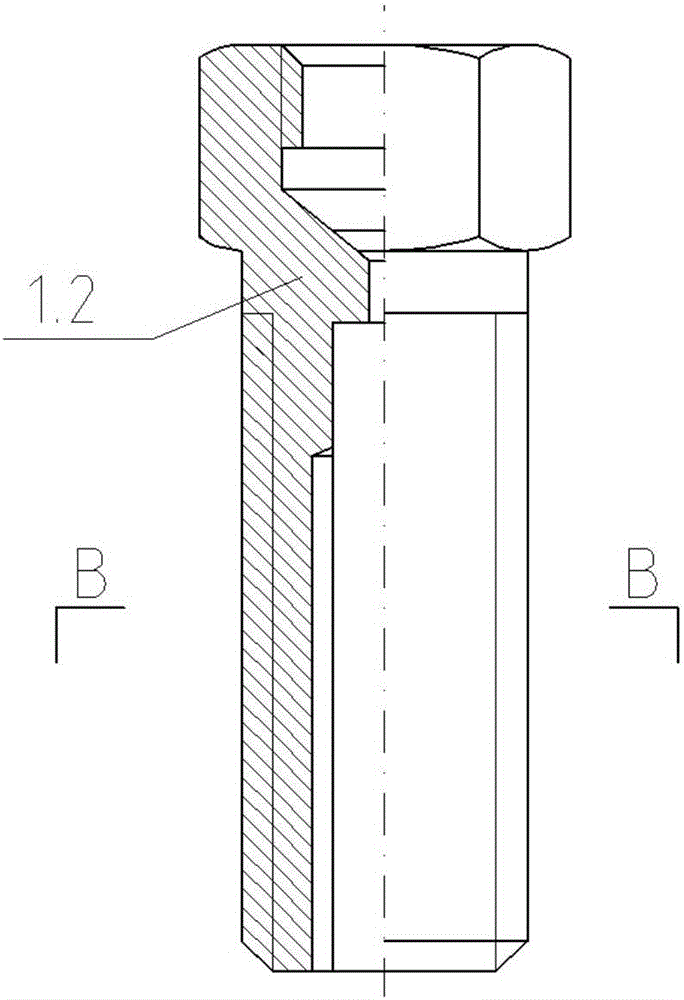

[0029] like Figure 1-19 As shown in the figure, the drain and exhaust check valve is composed of a check valve 1, a check valve 1, a check cover 2, an upper cylinder 3, a heightened cylinder 4, a middle cylinder 5, an isolation layer 6 and a lower cylinder 7. The isolation layer 6 is the anti-penetration geomembrane, the lower part of the anti-breathing and permeable valve 1 is sleeved with an O-type sealing ring I, and the lower thread of the anti-breathing and permeable valve 1 is connected with the upper end thread of the anti-water permeable cover 2, wherein the O-type sealing ring 1 is to prevent external The water penetrates into the reverse water permeable cover 2. The lower end of the reverse water permeable cover 2 is equally divided into four guide strips which are inserted into the grooves at the upper end of the upper cylinder 3 and can slide up and down with clearance fit. Ring 2.2, in which the T-shaped sealing ring 2.2 is used to prevent external water from inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com