A light alloy and composite material high-efficiency heterogeneous joint and its preparation method

A light alloy and composite material technology, applied in the direction of chemical instruments and methods, metal layered products, synthetic resin layered products, etc., can solve the problems of environmental pollution, expensive, performance damage of connectors, etc., to achieve short construction period, Low cost and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

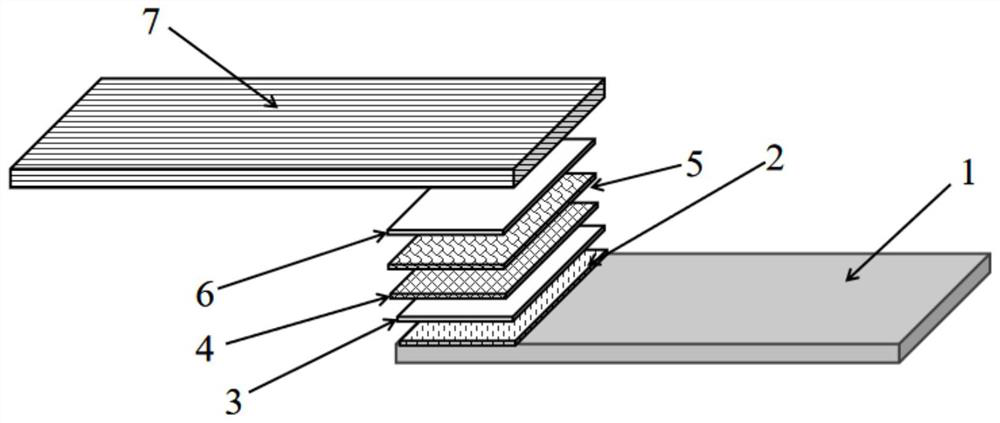

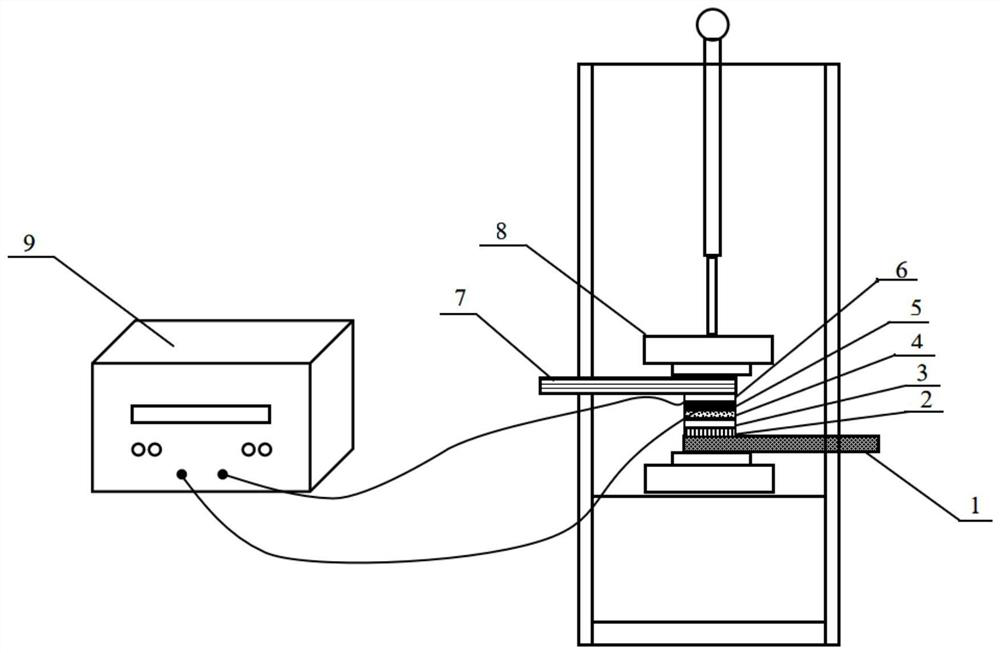

[0037] A method for preparing a light alloy and composite material high-efficiency heterogeneous joint, comprising the following steps:

[0038] Step 1: Light alloy surface pretreatment

[0039] The titanium alloy sample is polished with 400 mesh sandpaper to obtain the pretreated titanium alloy;

[0040] Step 2: Preparation of CNT layer by flame method

[0041] A nickel nitrate solution with a substance concentration of 1 mol / L is evenly sprayed on the surface of the polished titanium alloy through a spray gun, and dried to obtain a catalyst-loaded titanium alloy;

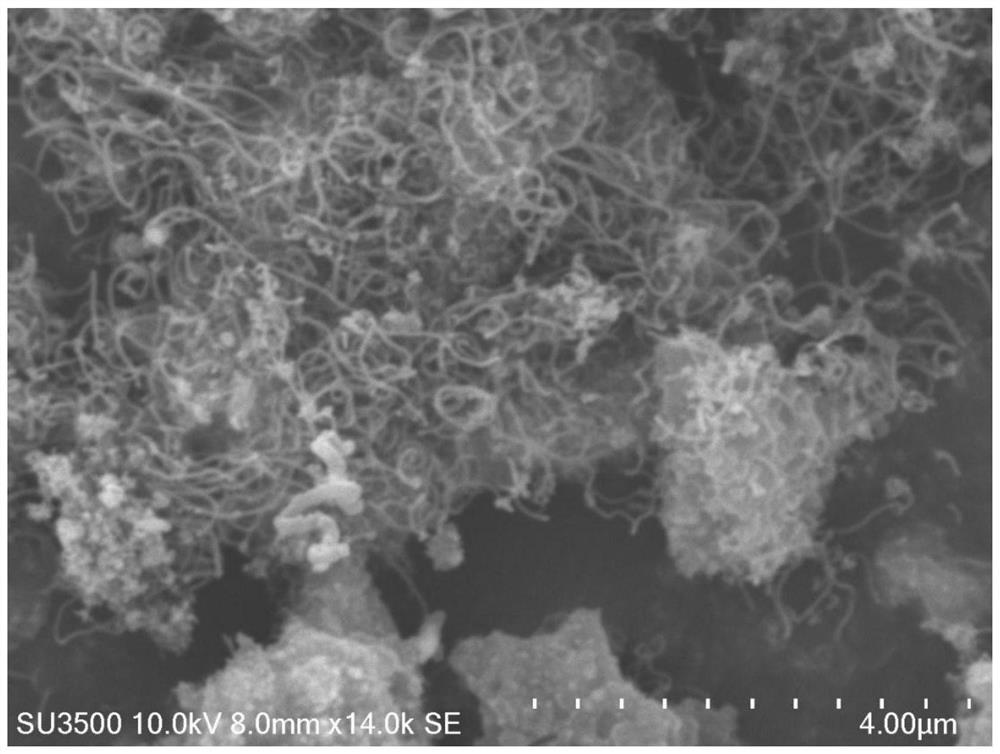

[0042] Put the catalyst-loaded titanium alloy to be welded at the position where the temperature of the alcohol flame is 1000 ° C, stay for 10 minutes, and generate an intertwined CNT layer on the surface of the titanium alloy to be bonded, and prepare a titanium alloy with a CNT layer; for the preparation The loaded CNT layer titanium alloy was subjected to SEM scanning analysis, and the SEM image of the CNT la...

Embodiment 2

[0047] A method for preparing a light alloy and composite material high-efficiency heterogeneous joint, comprising the following steps:

[0048] Step 1: Light alloy surface pretreatment

[0049] Polish the aluminum alloy sample with 400 mesh sandpaper to obtain the pretreated aluminum alloy;

[0050] Step 2: Preparation of CNT layer by flame method

[0051] A nickel nitrate solution with a substance concentration of 1 mol / L is evenly sprayed on the surface of the polished aluminum alloy through a spray gun, and dried to obtain a catalyst-loaded aluminum alloy;

[0052] Put the catalyst-loaded aluminum alloy to be welded at the position where the temperature of the alcohol flame is 800 ° C, stay for 10 minutes, and generate intertwined CNT layers on the surface of the aluminum alloy to be bonded, and prepare the CNT-loaded aluminum alloy.

[0053] Step 3: Preparation of efficient heterogeneous joints in lightweight alloys and composites

[0054] Place the first PEI film, sta...

Embodiment 3

[0057] A method for preparing a light alloy and composite material high-efficiency heterogeneous joint, comprising the following steps:

[0058] Step 1: Light alloy surface pretreatment

[0059] The titanium alloy sample is polished with 400 mesh sandpaper to obtain the pretreated titanium alloy;

[0060] Step 2: Preparation of CNT layer by flame method

[0061] A nickel nitrate solution with a substance concentration of 1 mol / L is evenly sprayed on the surface of the polished titanium alloy through a spray gun, and dried to obtain a catalyst-loaded titanium alloy;

[0062] Put the catalyst-loaded titanium alloy to be welded at a position where the temperature of the alcohol flame is 1000 ° C, and stay for 20 minutes, and generate intertwined CNT layers on the surface of the titanium alloy to be bonded, and prepare a titanium alloy with a CNT layer.

[0063] Step 3: Preparation of efficient heterogeneous joints in lightweight alloys and composites

[0064] Place the first P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com