A method for utilizing livestock and poultry slaughter waste

A waste, livestock and poultry technology, applied in the field of utilization of livestock and poultry slaughtering waste, to achieve the effect of prolonging the coagulation time, excellent cost performance, and enhanced flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

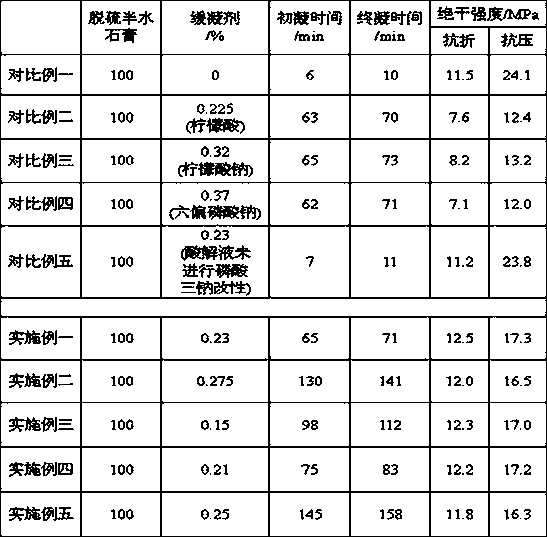

Examples

Embodiment 2

[0026] Example 2 Add 8 parts of pork bone, 40 parts of pork, 2 parts of pig fur, 45 parts of concentrated hydrochloric acid and 95 parts of water into the reactor, stir for acid hydrolysis, the hydrolysis temperature is 94°C, and the hydrolysis time is 7 hours. Cool down after the reaction , filtered to obtain the mixed solution; adding trisodium phosphate solution, modifying the pH of the mixed solution to 8, and obtaining a gypsum retarder.

[0027] The desulfurization hemihydrate gypsum was mixed with the retarder (in terms of solid content) prepared in this example, and the water-material ratio was 0.58, and the setting time and strength performance tests were carried out.

Embodiment 3

[0028] Example 3 Add 12 parts of sheep bone, 25 parts of mutton, 5 parts of sheep fur, 40 parts of concentrated hydrochloric acid and 100 parts of water into the reactor, stir for acid hydrolysis, the hydrolysis temperature is 90°C, and the hydrolysis time is 5 hours. Cool down after the reaction , and filtered to obtain the mixed solution; adding trisodium phosphate solution to modify the pH of the mixed solution to 9 to obtain a gypsum retarder.

[0029] The desulfurization hemihydrate gypsum was mixed with the retarder (in terms of solid content) prepared in this example, and the water-material ratio was 0.58, and the setting time and strength performance tests were carried out.

Embodiment 4

[0030] Example 4 Add 47 parts of chicken, 5 parts of chicken feathers, 47 parts of concentrated hydrochloric acid and 92 parts of water into the reactor, stir for acid hydrolysis, the hydrolysis temperature is 96°C, and the hydrolysis time is 6 hours. After the reaction is completed, cool and filter to obtain the mixed solution; Trisodium phosphate solution is added to modify the pH of the mixed solution to 7 to obtain a gypsum retarder.

[0031] The desulfurization hemihydrate gypsum was mixed with the retarder (in terms of solid content) prepared in this example, and the water-material ratio was 0.58, and the setting time and strength performance tests were carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com