Glue injection clamp element used in window frame manufacturing process

A production process and window frame technology, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of labor-consuming, affecting the appearance, uneven glue application, etc., to improve strength, improve production efficiency, and solve rainwater leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

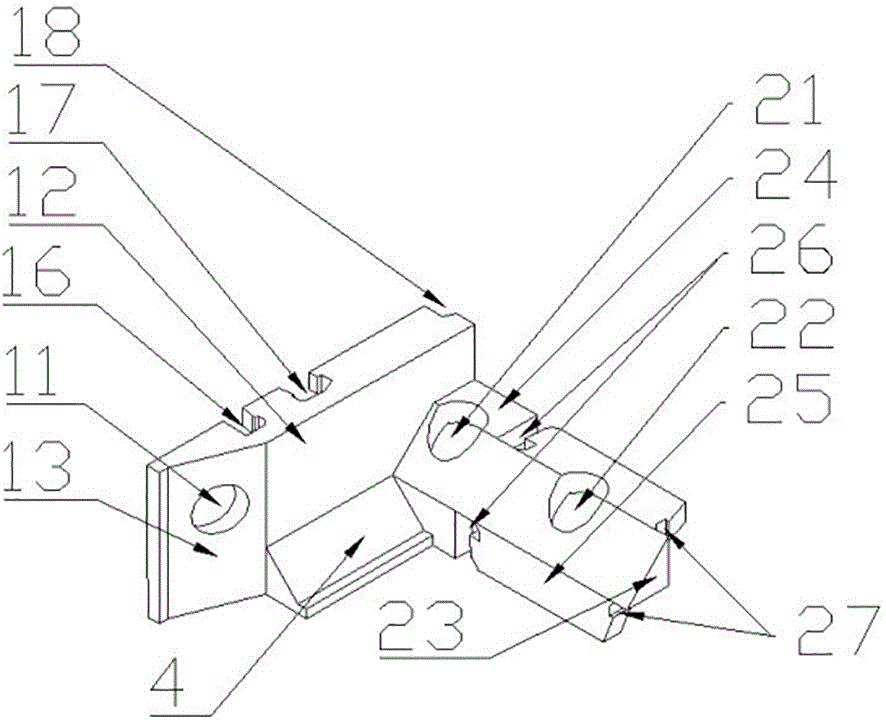

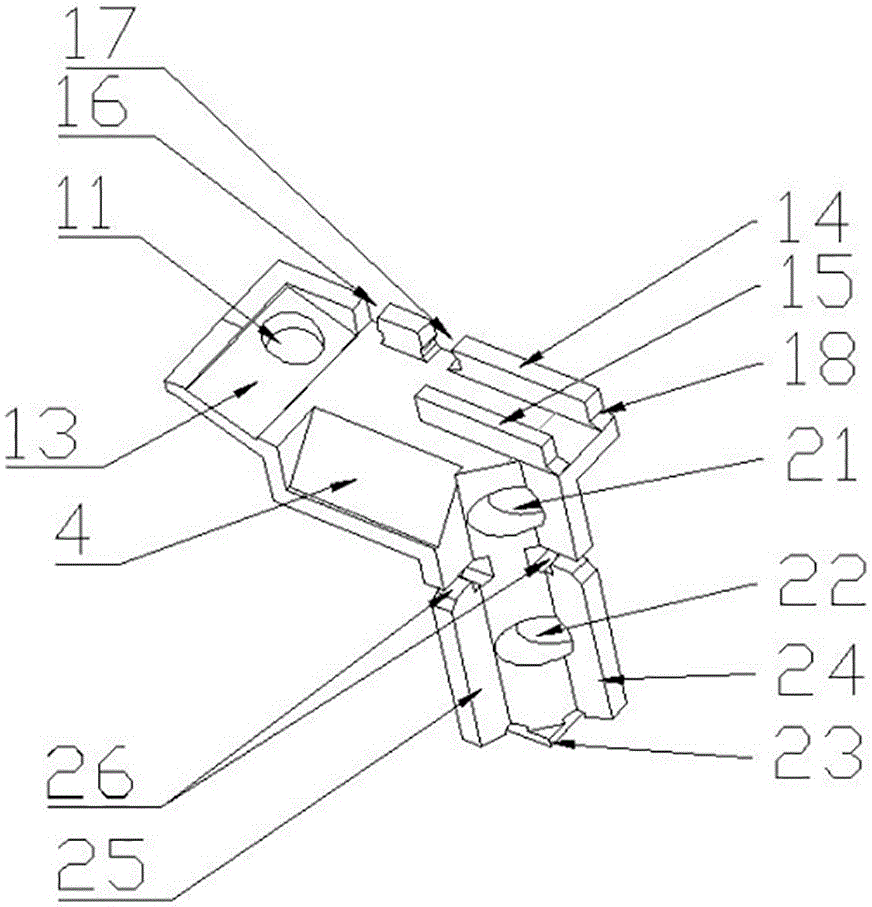

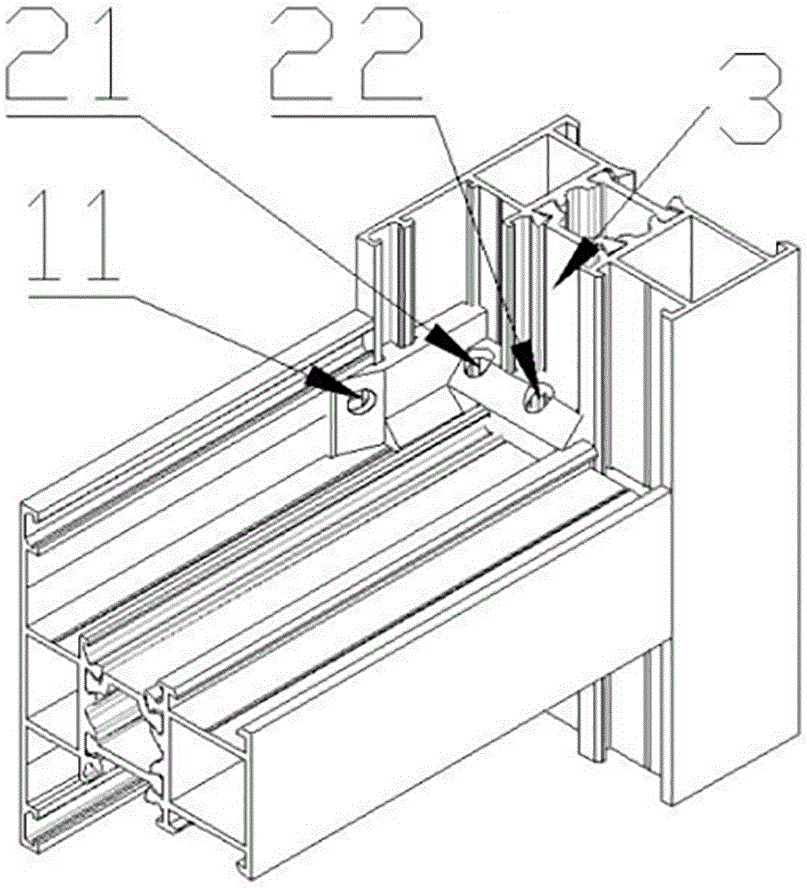

[0014] Such as figure 1 and figure 2 As shown, in order to facilitate the fitting of the clip with the window frame profile and at the same time play the role of a super strong clip, the glue injection clip according to the present invention includes a first base, and one end of the first base is vertically fixedly connected with a The second pedestal, the lower part of the first pedestal is provided with a reinforcement 4 to connect the first pedestal and the second pedestal.

[0015] Such as figure 1 and figure 2 As shown, in order to directly form the first sealed cavity between the back of the first base and the window frame profile 3, the neutral silicon-copper sealant is injected into the first sealed cavity through the first glue injection hole 11, so that the neutral silicon-copper sealant is Under the action of the extrusion force of the first sealing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com