Floating type constant-pressure tool apron device

A constant pressure, floating technology, applied in grinding drive device, automatic grinding control device, control of workpiece feed movement, etc., can solve the problems of inability to carry out grinding, poor control accuracy, inability to adjust the height of the tool seat, etc. To achieve the effect of easy installation and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

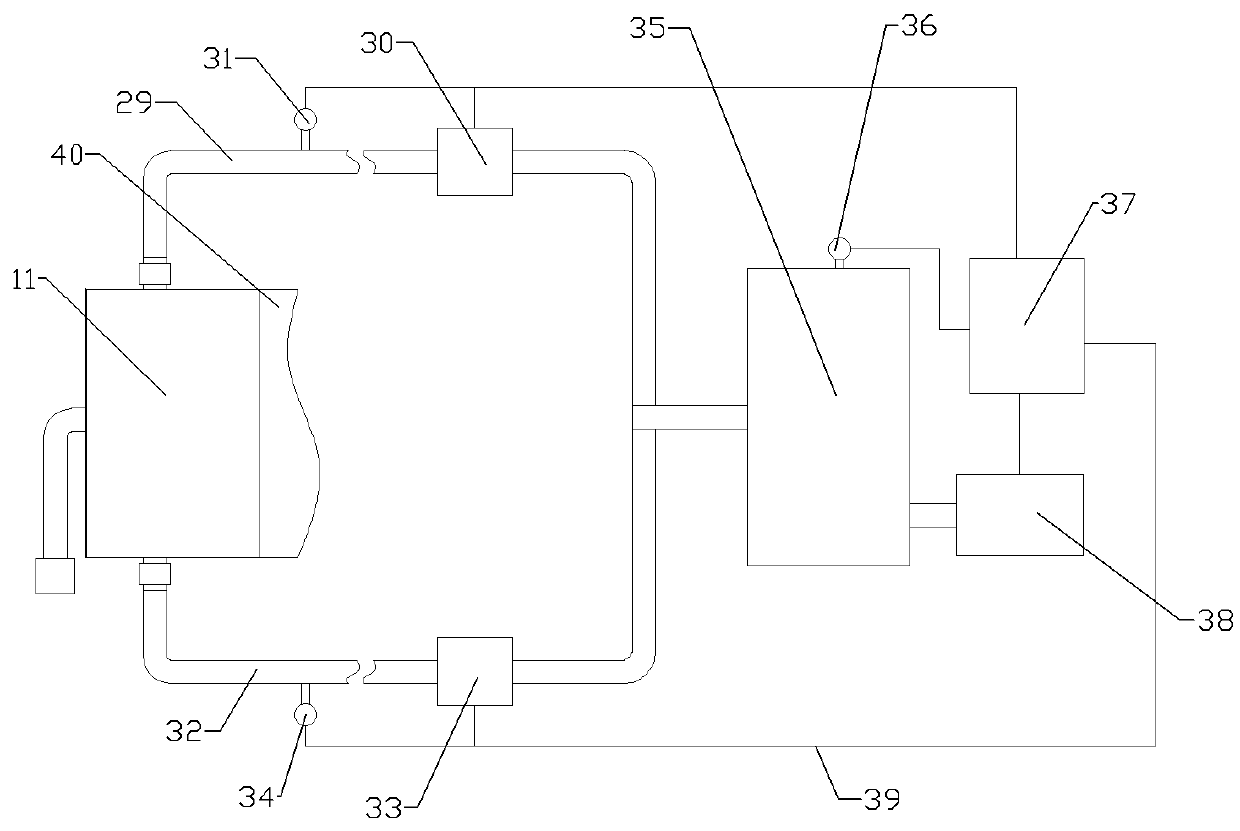

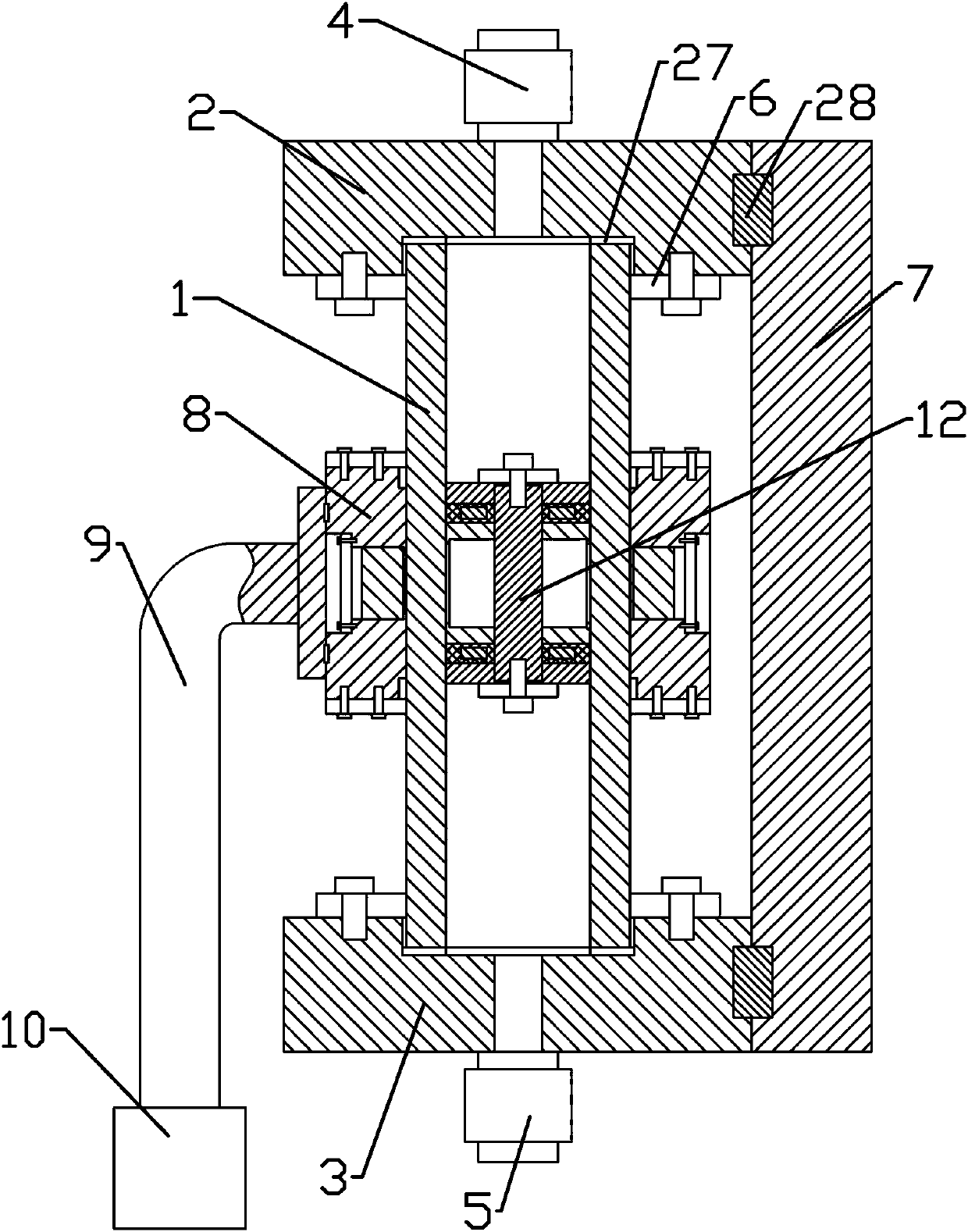

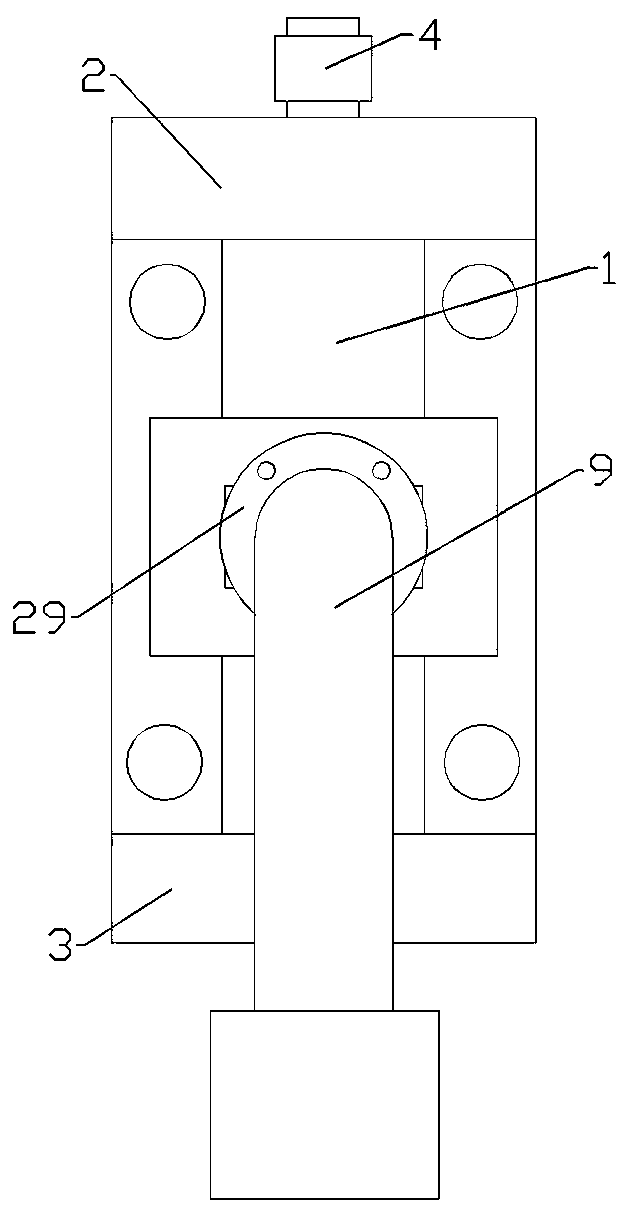

[0022] like Figure 1-5 As shown, a floating constant pressure tool seat device includes a moving seat 40 that can move along a horizontal plane. The moving seat is a gantry seat that can move along the X-axis and Y-axis. Seat 11, comprises hard trachea 1, and trachea is copper pipe or stainless steel pipe, and trachea is prismatic, and in the present embodiment, trachea is stainless steel square steel pipe, thermoplastic molding, upper end of trachea is equipped with upper seat plate 2, and trachea lower end is installed with The lower seat plate 3, the upper seat plate and the lower seat plate are all aluminum alloy plates, which are light in weight, high in structural strength, and easy to process. The air pipes are respectively sealed and connected with the upper seat plate and the lower seat plate. The lower end is sealed and communicated with a lower air pipe joint 5, specifically, through holes are processed on the upper seat plate and the lower seat plate, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com