Online detection method for the spatial position of roller axis based on machine vision

A technology of roll axis and spatial position, applied in instruments, measuring devices, optical devices, etc., can solve the problems of difficult roll space position equipment and product quality, and achieve the effect of solving equipment and product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

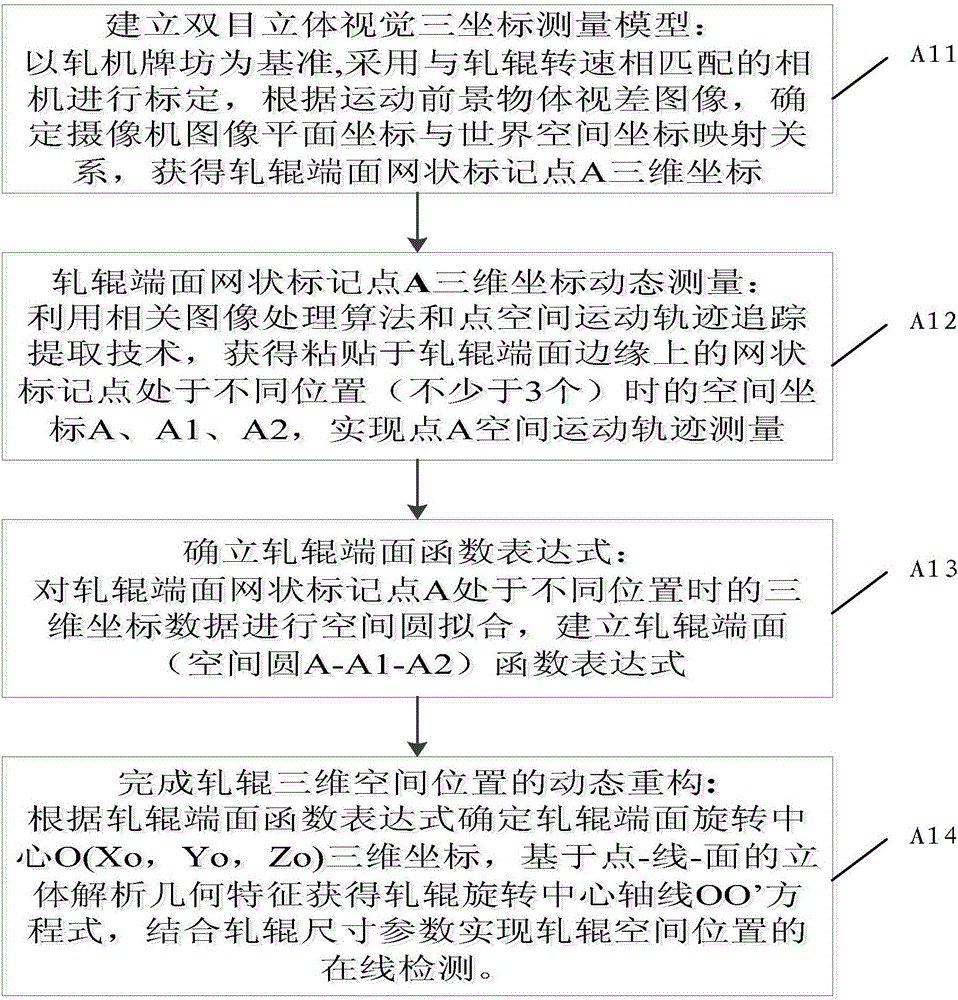

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0041] The present invention aims at the existing equipment and product quality problems caused by the difficulty in online detection of the spatial position of the roll, and provides an online detection method of the spatial position of the roll axis based on machine vision.

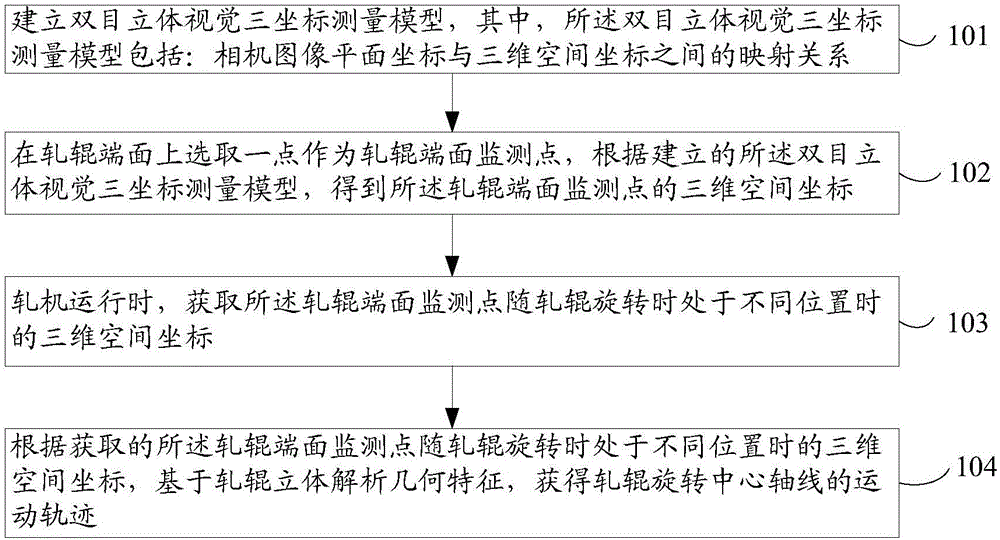

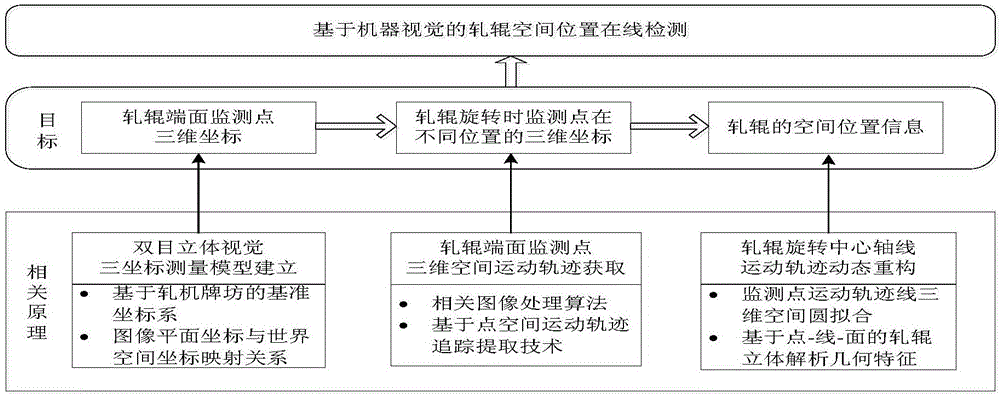

[0042] Such as figure 1 As shown, the machine vision-based online detection method for the spatial position of the roll axis provided by the embodiment of the present invention includes:

[0043] S101. Establish a binocular stereo vision three-coordinate measurement model, wherein the binocular stereo vision three-coordinate measurement model includes: a mapping relationship between camera image plane coordinates and three-dimensional space coordinates;

[0044] S102, selecting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com