The impact test device and method of the falling mechanism of the front subframe of the automobile

A technology of front subframe and impact test, which is applied in the direction of vehicle impact test, machine/structural component test, impact test, etc. It can solve the problems of inconvenient operation and inability to truly and effectively simulate the working conditions of automobiles, so as to achieve convenient operation, The effect of reliable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

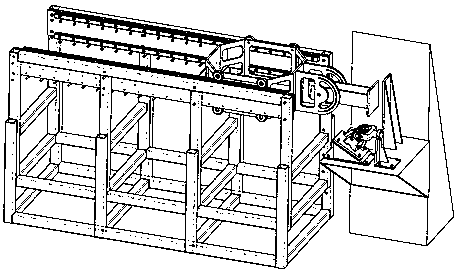

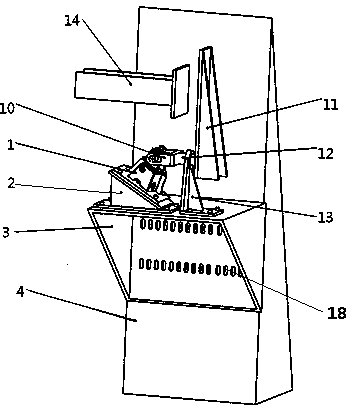

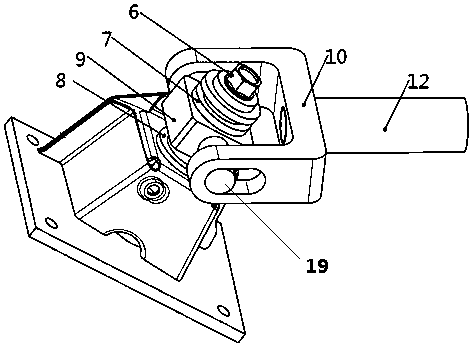

[0033] like figure 1 As shown, the impact test device of the present invention consists of two parts: a clamp device and a driving device. like Figure 5 , figure 2 As shown, the driving device has an impact head 14 , and the clamping device is provided with an impact block 11 matched with the impact head 14 . like figure 2 , image 3 As shown, the outer side of the front sub-frame sample 1 is provided with a shaft sleeve 8 and a pull-off device body 9, such as Figure 4 As shown, the inside of the front sub-frame sample is provided with a fixing nut 5, and the fixing nut 5 is a projection welding nut. like figure 2 , image 3 As shown, the long bolt 6 passes through the pull-off device body 9, the axle sleeve 8, and is fixed with the fixing nut 5 in turn; when the long bolt 6 is connected with the fixing nut 5, it passes through the bolt hole 20 on the front sub-frame sample, as shown in FIG. Image 6 The bolt holes are notched as shown. A certain twist is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com