Probe scanning tool suitable for detecting weld seams of different structures

A technology of structural welds and tools, which is applied in the design field of probe scanning tools, can solve the problems of continuous radiation of staff, affecting the continuity of detection signals, etc., and achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

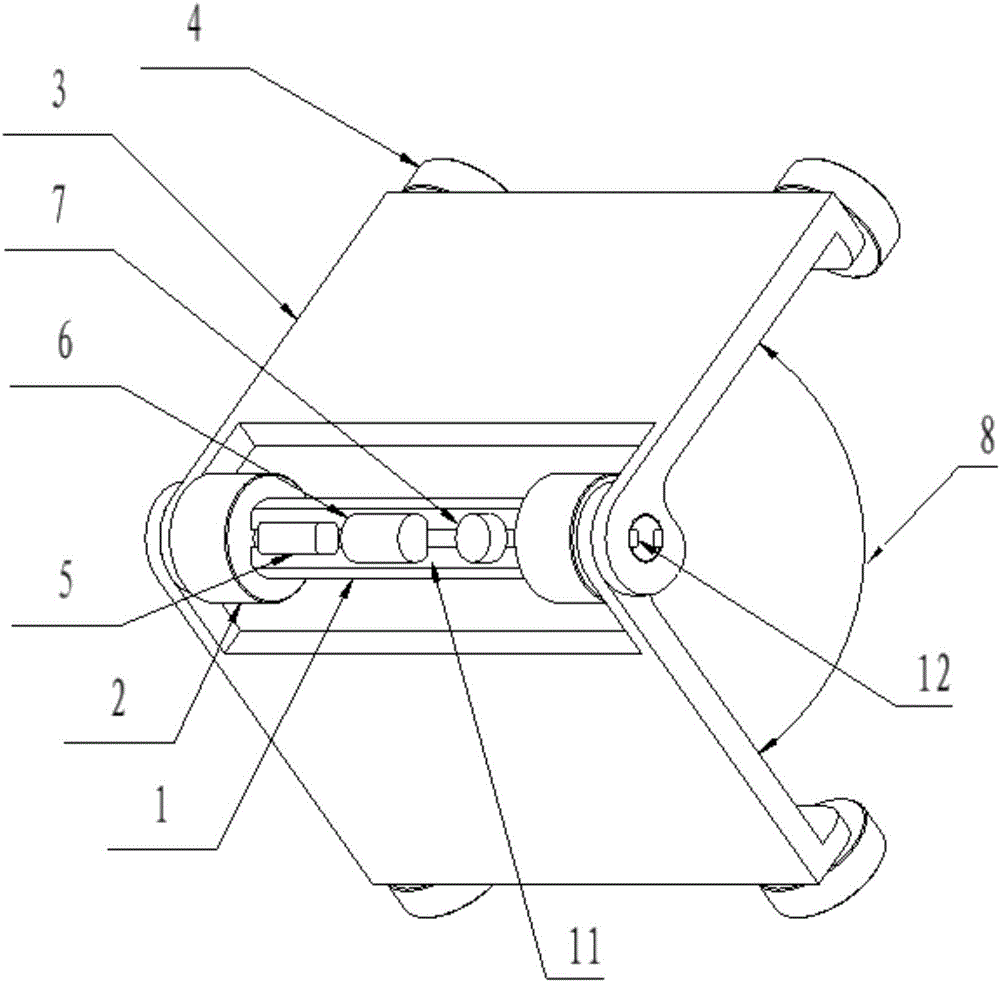

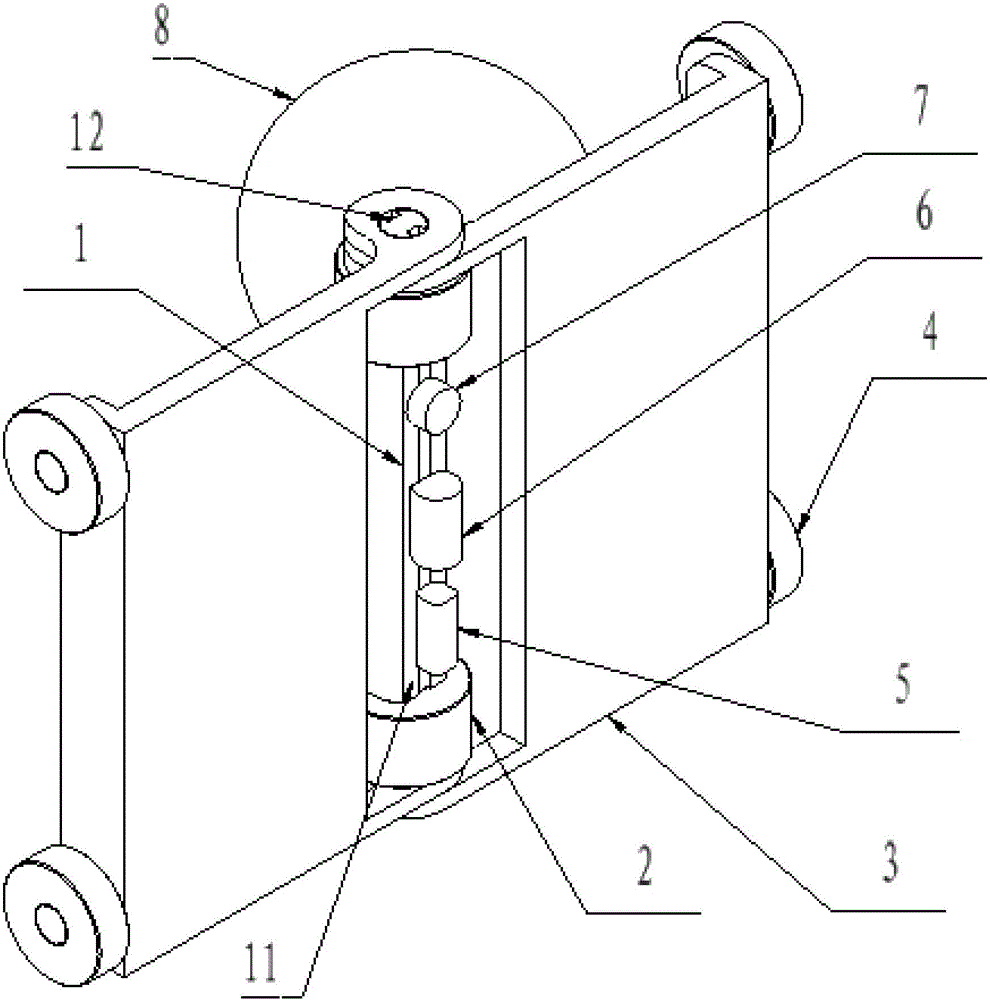

[0029] Such as figure 1 , figure 2 As shown, the present invention provides a probe scanning tool suitable for inspection of welds with different structures, including a mandrel 1, a roller 2, an auxiliary support plate 3, a roller 4, and a sensor, and the mandrel 1 is provided with a mandrel sensor installed The plane 11, the mandrel wiring groove 12, the angle between the two auxiliary support plates 3 is the support plate angle 8, and the sensors include A sensor 5, B sensor 6, and C sensor 7.

[0030] Two auxiliary support plates 3 are installed on the mandrel 1 through the roller 2 in the form of hinges. The two auxiliary support plates 3 can rotate around the mandrel 1 and can be stably limited to a certain angle according to the inspection object. In this embodiment The supporting plate angle 8 is selected as flat 180 degrees and vertical 90 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com