Uranium mining method by in-situ loosening and leaching

A leaching and in situ technology, applied in the field of uranium mining and smelting, can solve the problems of difficult support, easy collapse and falling blocks, and low efficiency.

Active Publication Date: 2014-07-23

BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(the average pumping volume is less than 0.8-1.2m3 / d), low efficiency and high cost; using conventional underground mining methods, the sandstone layer is relatively loose

Scattered, easy to collapse and drop blocks, difficult to support, and the ore-bearing aquifer layer has a large amount of water supply

There is currently no effective way to develop such mines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

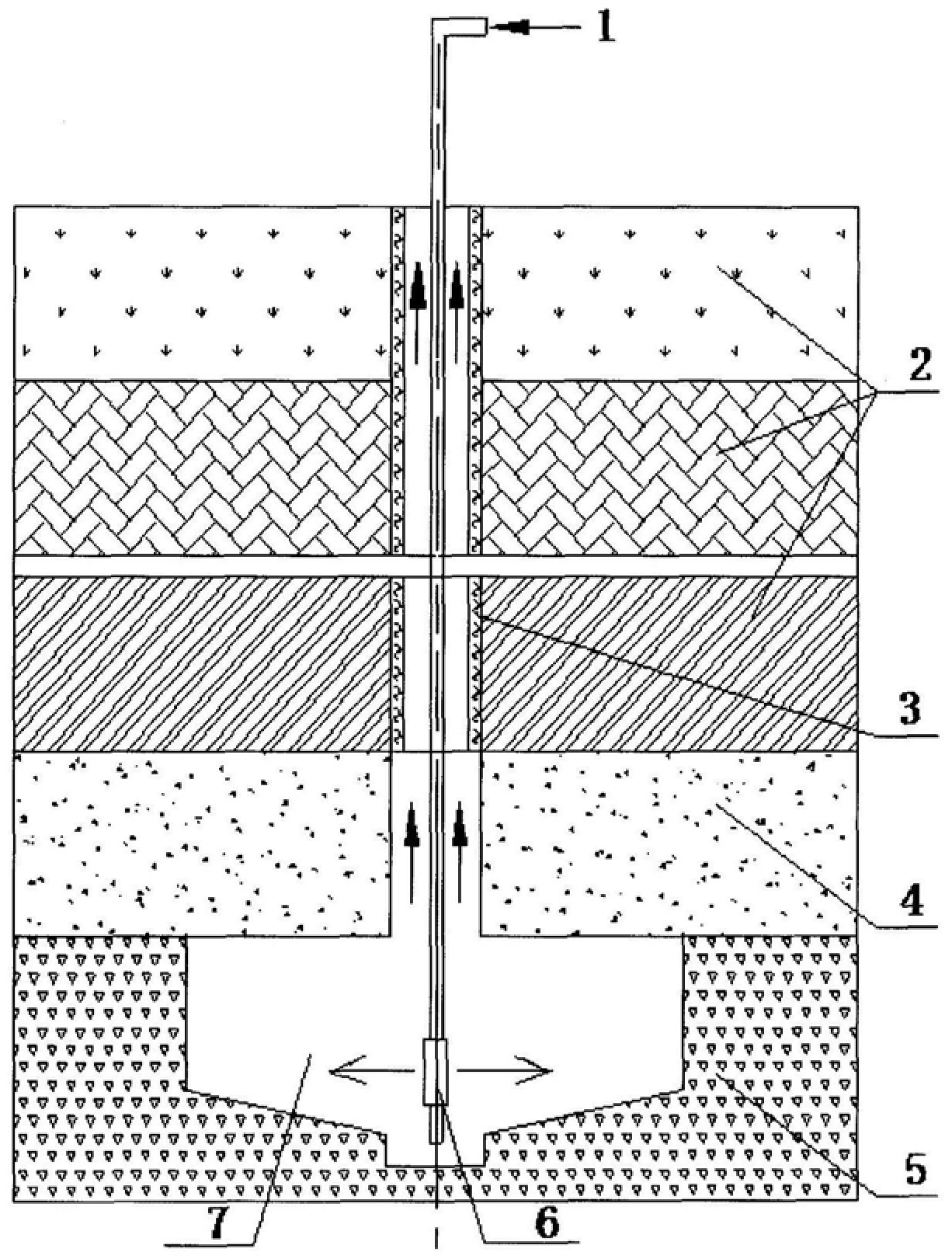

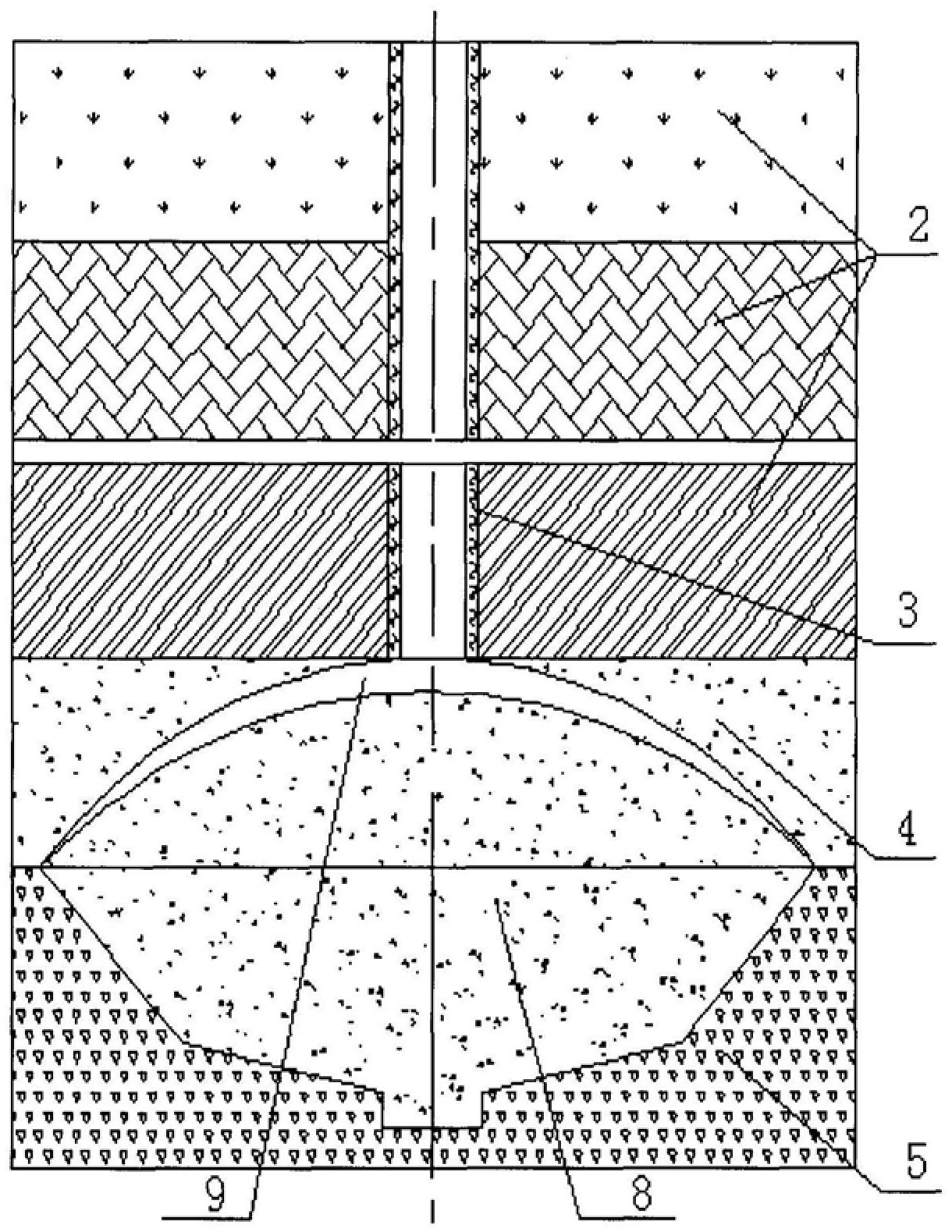

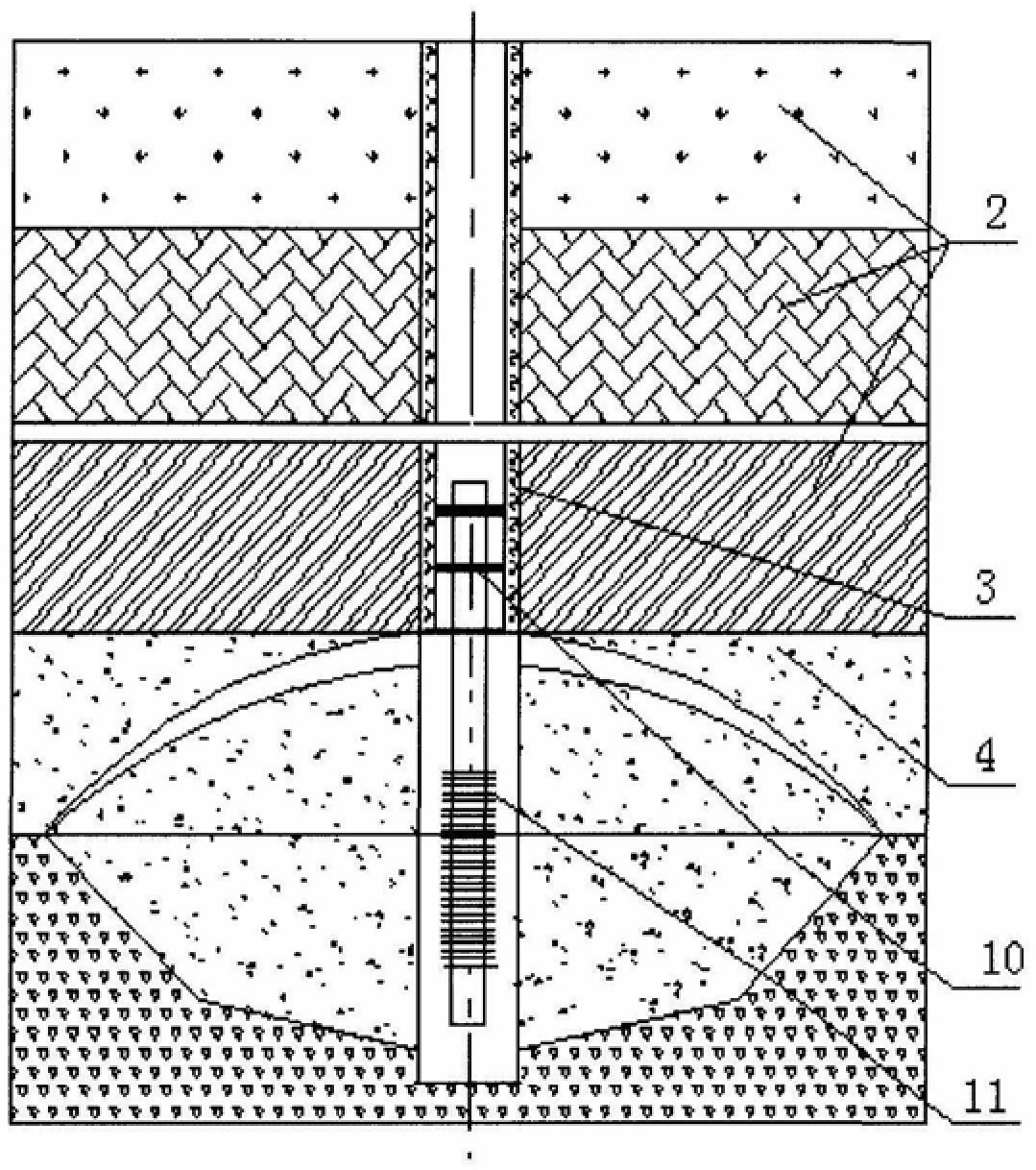

The invention provides a method for mining uranium by in-situ loosening and leaching. The steps are: (a) forming the borehole structure; (b) running the casing from the borehole into the ore-bearing aquifer; (c) running the hydraulic roadhead into the bottom of the borehole along the casing to excavate Form a compensation chamber with a circular plane; (d) adopt the method of blasting, and the caving ore falls into the compensation chamber to form a loose dome; (e) run the plug and the leaching borehole filter into the , forming a liquid pumping borehole; (f) drill 2 to 4 liquid injection boreholes around the liquid pumping borehole, and the bottoms of the liquid injection borehole and the liquid pumping borehole are located at the position of the compensation chamber; (g) from The leaching solution is injected into the liquid injection borehole, and the leaching solution containing useful metal components is extracted from the liquid suction borehole. The invention improves the permeability of the ore, reduces the gluing and mechanical blockage of clay substances in the ore, and maximizes the pumping and injection volume of the ground leaching borehole.

Description

In-situ loosening and leaching uranium mining method Technical field [0001] The present invention relates to the technical field of uranium mining and smelting, in particular to a method for mining uranium by loosening and leaching in situ. Background technique There is a large amount of low-permeability sandstone uranium deposits in my country at present, as Inner Mongolia Ordos Basin sandstone uranium deposits, The amount of uranium resources is nearly 10,000 tons, but the average permeability coefficient of the ore layer is less than 0.165m / d. The average permeability coefficient of the bed is 0.5m / d, and the ore body is in the form of agglomerates and blocks. These deposits are mined by in-situ leaching, and the boreholes pump out less liquid (the average pumping volume is less than 0.8-1.2m3 / d), low efficiency and high cost; using conventional underground mining methods, the sandstone layer is relatively loose Scattered, easy to collapse and drop blocks, difficul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/10C22B3/02

Inventor 胡柏石姜岩牛玉清谭亚辉

Owner BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com