Automatic garlic planter

A planter and garlic technology, applied in the direction of single-seed planter, planter parts, etc., can solve the problems of inability to achieve erection of the cusp upwards, failure to meet the requirements of garlic planting, and high labor intensity of staff, and to improve erection and erection. High planting rate, high seeding depth qualification rate and good seeding depth consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

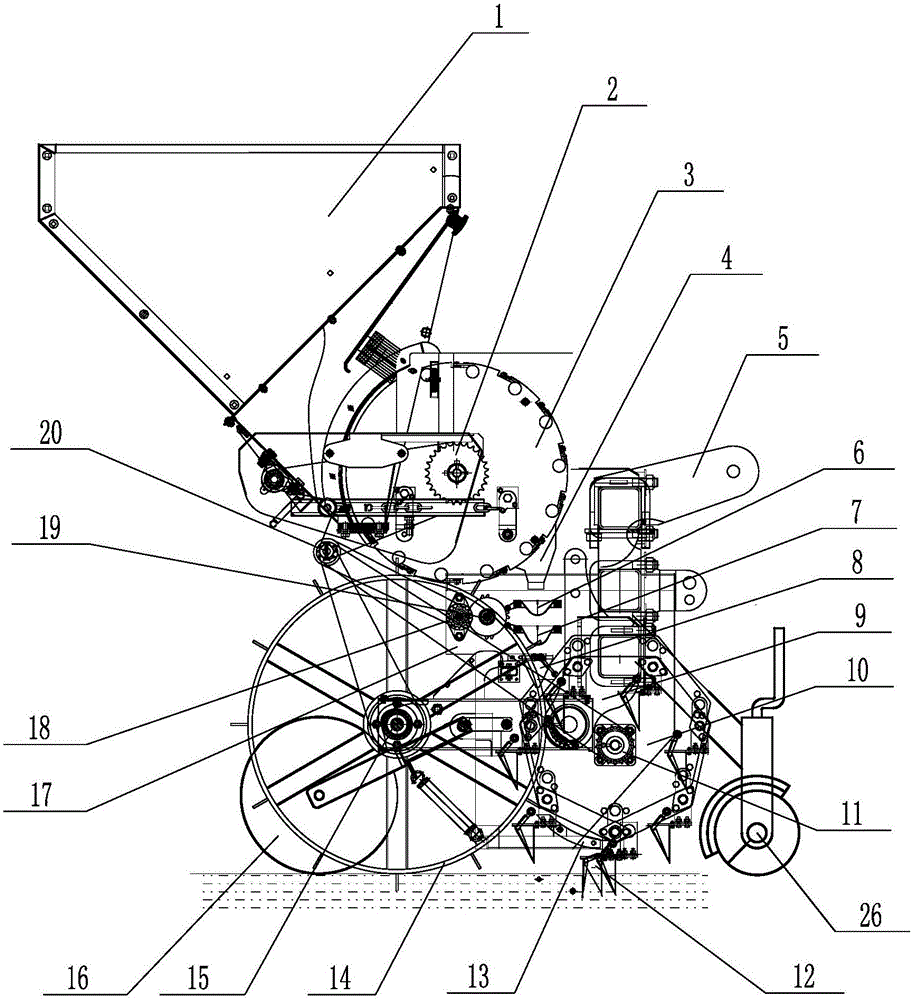

[0024] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

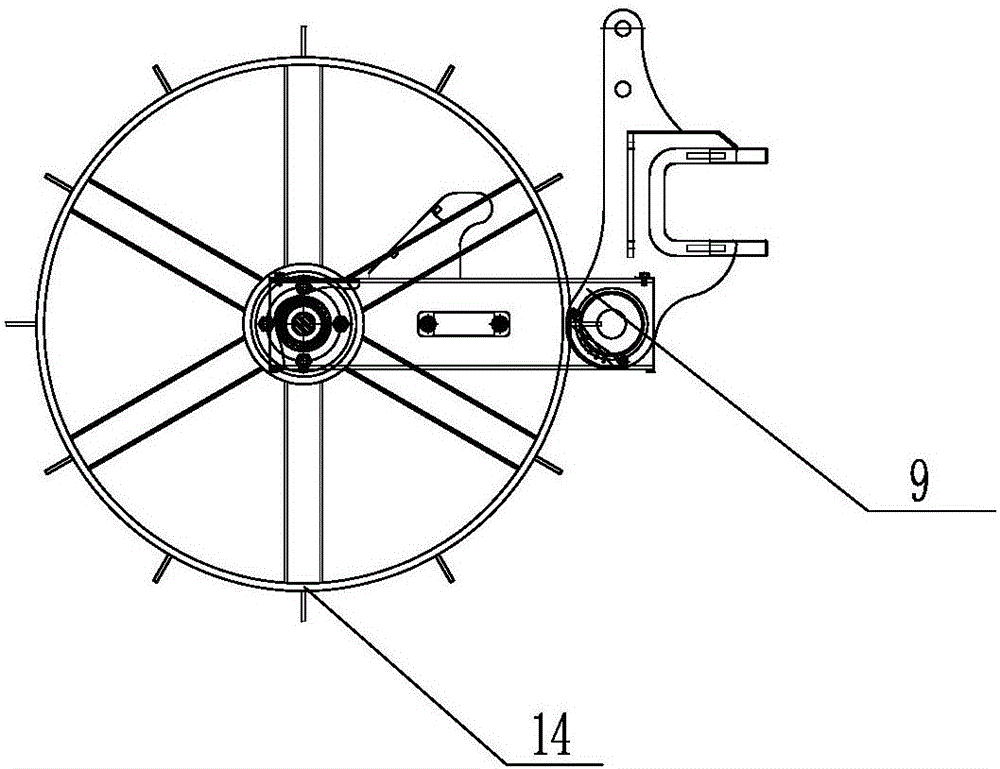

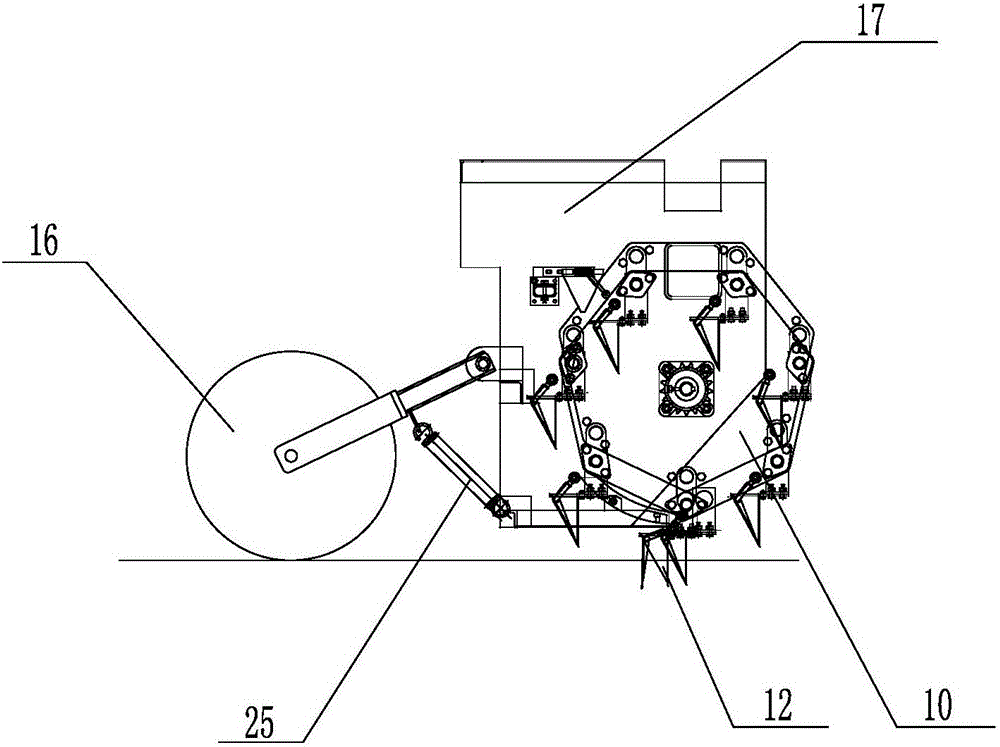

[0025] Such as Figure 1-3 As shown, the automatic garlic planter of the present invention includes a frame 17, and the top of the frame 17 fixes the seed box 1 and the seed meter 3, and the outlet of the seed box 1 corresponds to the entrance of the seed meter 3, and is characterized in that : The seed discharge outlet 4 of the seed metering device 3 is corresponding to the upper directional bucket 6 arranged below the seed metering device 3, and the lower directional bucket 7 is correspondingly arranged below the upper directional bucket 6, and the corresponding upper directional bucket 6 and the lower directional bucket 7 are in the The rear part is provided with a directional bucket opening device 19 and a directional bucket opening transmission device 18, the directional bucket opening device 19 and the directional bucket opening transmission device 18 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com