Optical fiber connector cleaning belt and manufacturing method thereof

An optical fiber connector and a production method technology are applied in the field of optical fiber connector cleaning tools, optical fiber connector cleaning tape production, and optical fiber connector cleaning tape fields, which can solve the problem of poor cleaning effect of the cleaning tape, unstable cleaning tape size, and affecting the cleaning effect. and other problems, to achieve good dimensional stability, meet cleaning needs, and improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

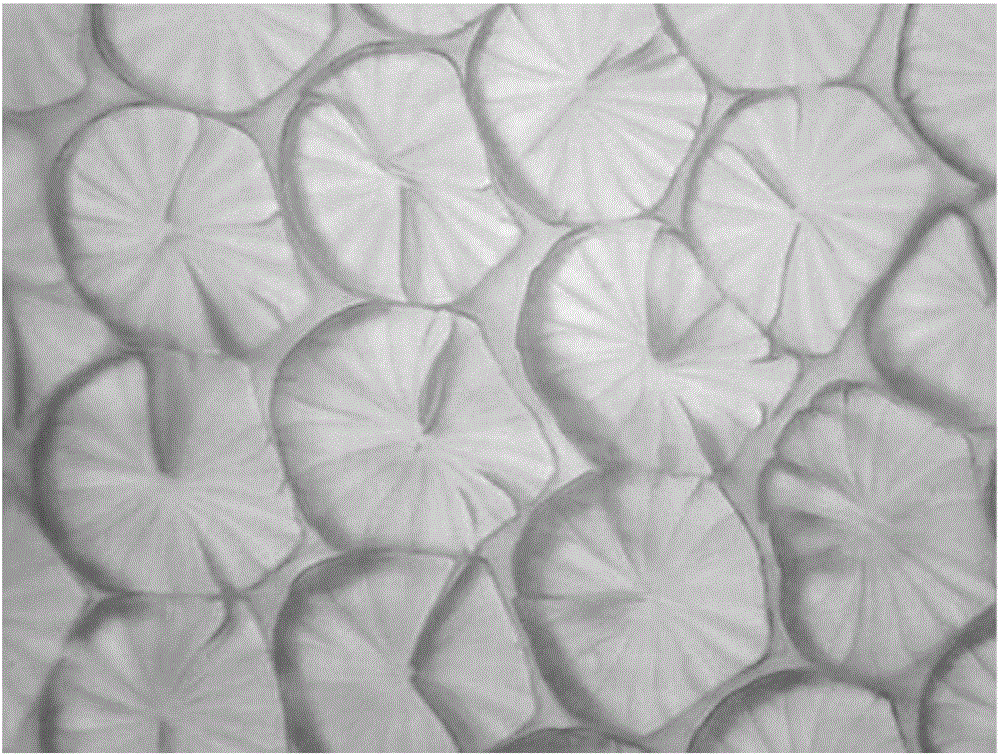

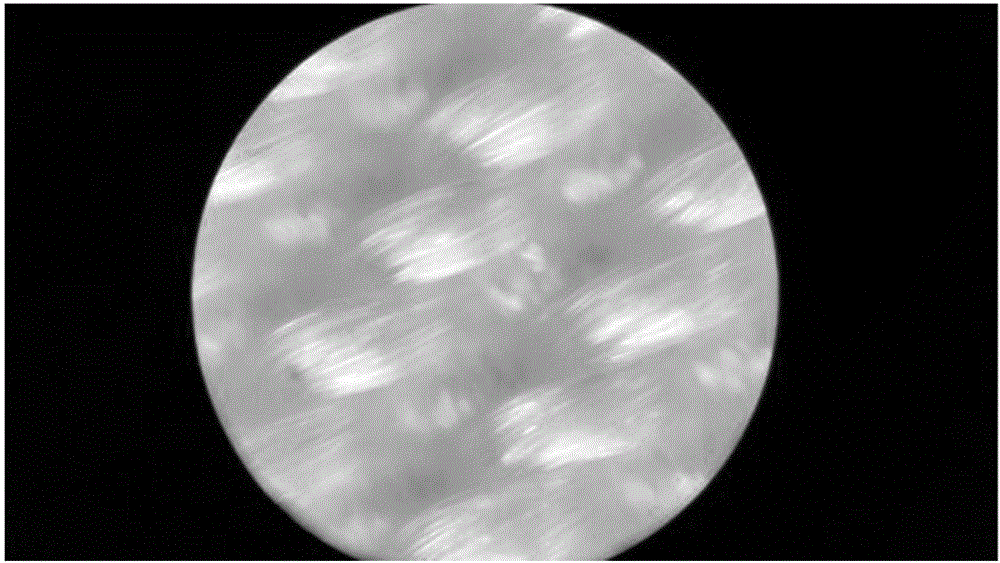

[0021] As shown in the attached figure, an optical fiber connector cleaning tape is a flat tape structure with a width of 1.0-30.0 mm, which is woven from polyester-nylon composite superfine fibers through a loom. It is produced by the following methods: (1) Using orange petal-type polyester-nylon composite fibers, selecting fibers of different deniers as warp and weft respectively, formulating a suitable weaving density according to the requirements of use, and using a textile machine to weave a width of 1.0-30.0mm flat fiber tape, wherein the textile machine equipment used is a special narrow-width textile machine, which is the prior art, and the monofilament fineness of the orange segment type polyester-nylon composite fiber is selected as 1.5-3.0 denier, The ratio of polyester and nylon (by mass percentage) is selected as 60 / 40-80 / 20, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com