Layered dairy cow feeding system and feeding method

A layered, dairy technology, applied in animal feeding devices, animal houses, other equipment, etc., can solve problems such as affecting the health of the herd, consuming manpower and material resources, and increasing the probability of bringing in germs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

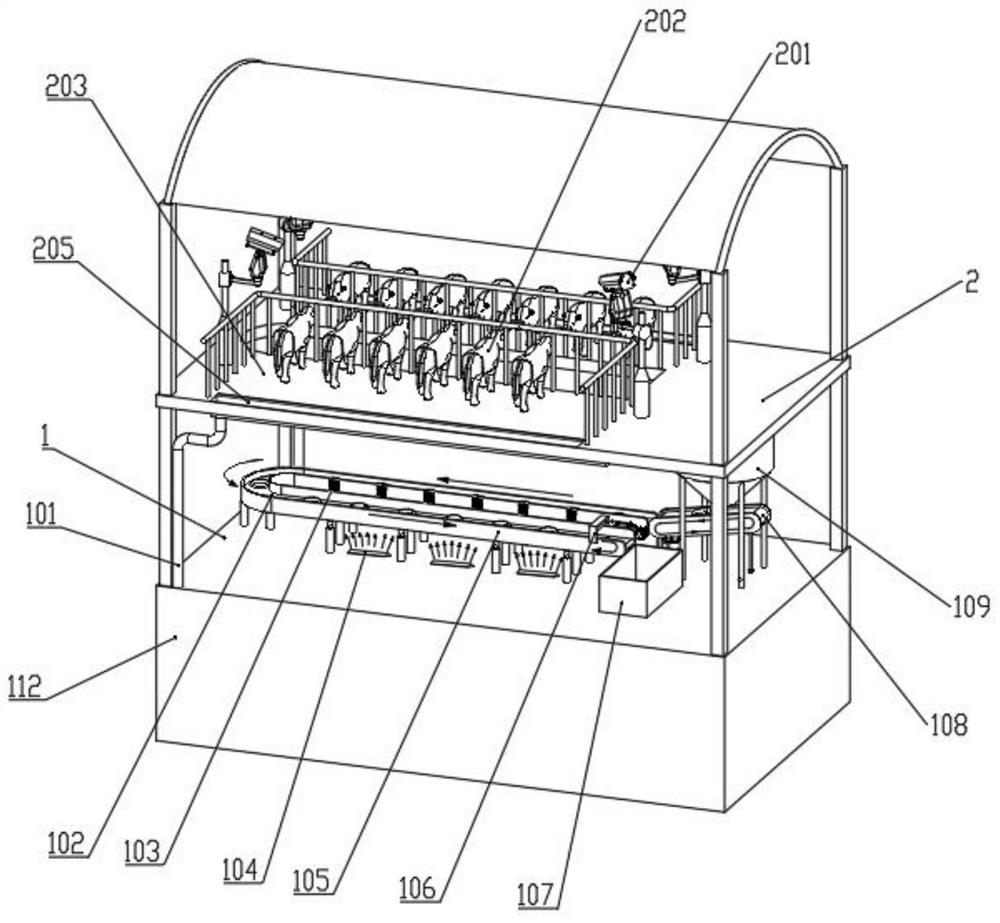

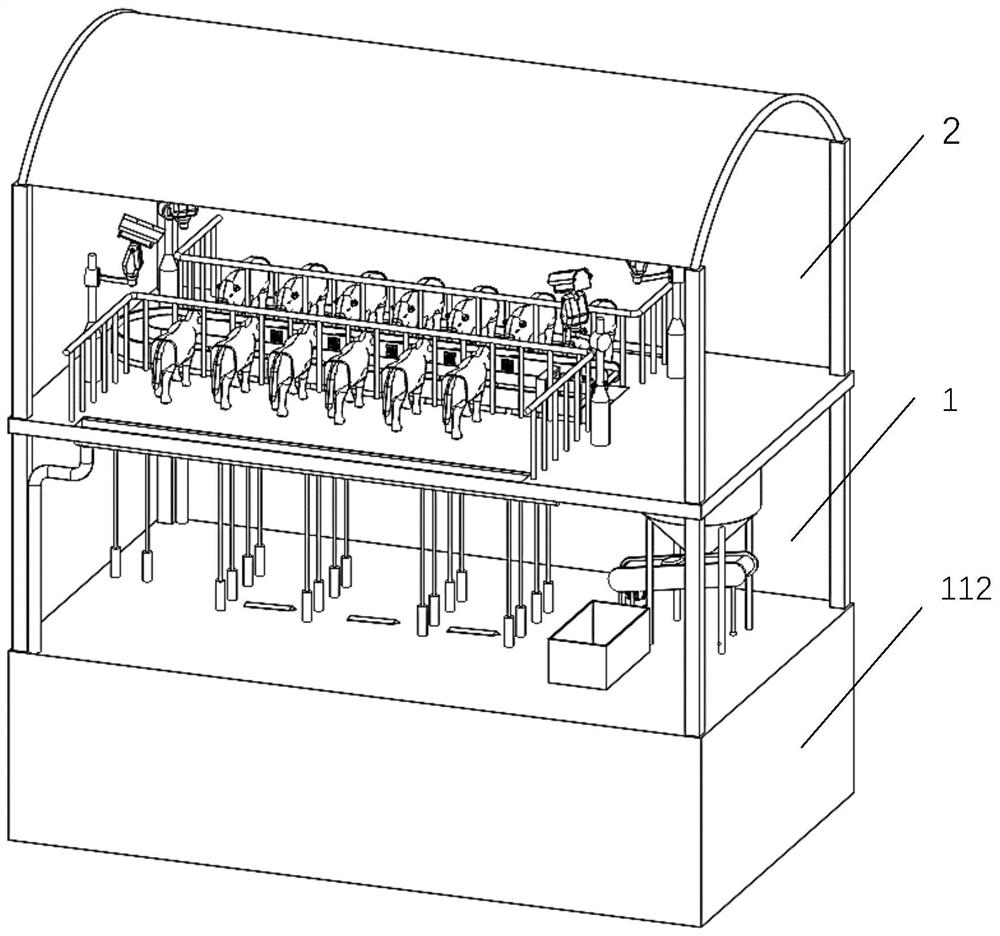

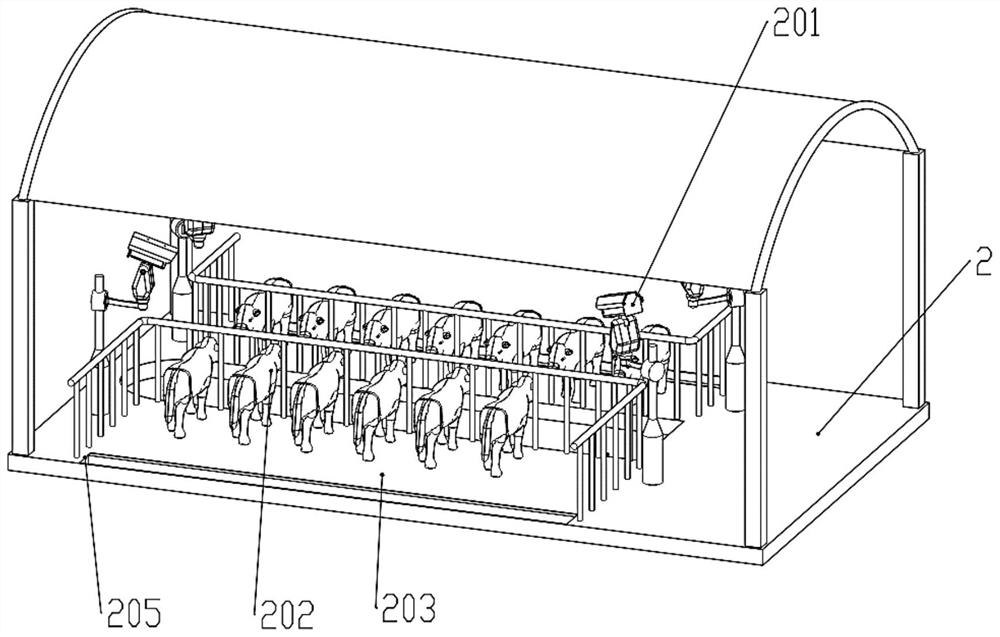

[0044] like figure 1 and figure 2 A layered cow feeding system shown includes a feeding layer 2 and a feed supply layer 1; the feeding layer 2 and the feed supply layer 1 are separated by a partition layer to form an upper and lower independent space layer; An opening is provided in the middle of the partition layer, and a partition 204 is provided at the opening. The partition 204 moves laterally under the push of the driving motor 206 . After the partition 204 moves to one side, the feeding layer 2 communicates with the feed supply layer 1 .

[0045] like Figure 4 and Figure 5 As shown, the feed supply layer 1 includes a batching machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com