Preparation method of welding wire for shipping and ocean engineering alloy steel supporting welding

A technology of welding wire and formula, which is applied in the direction of welding equipment, welding equipment, welding medium, etc., and can solve problems such as accelerated weld corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] According to the chemical composition and production process requirements of the flux-cored wire core powder of the present invention, three batches of 10CrSiNiCu steel matching flux-cored wires were produced. The base metal and welding process parameters of the three batches of welding wire are shown in Table 2. After welding, the mechanical performance test and seawater natural immersion potential measurement were carried out on the obtained deposited metal. The test results are shown in Table 3.

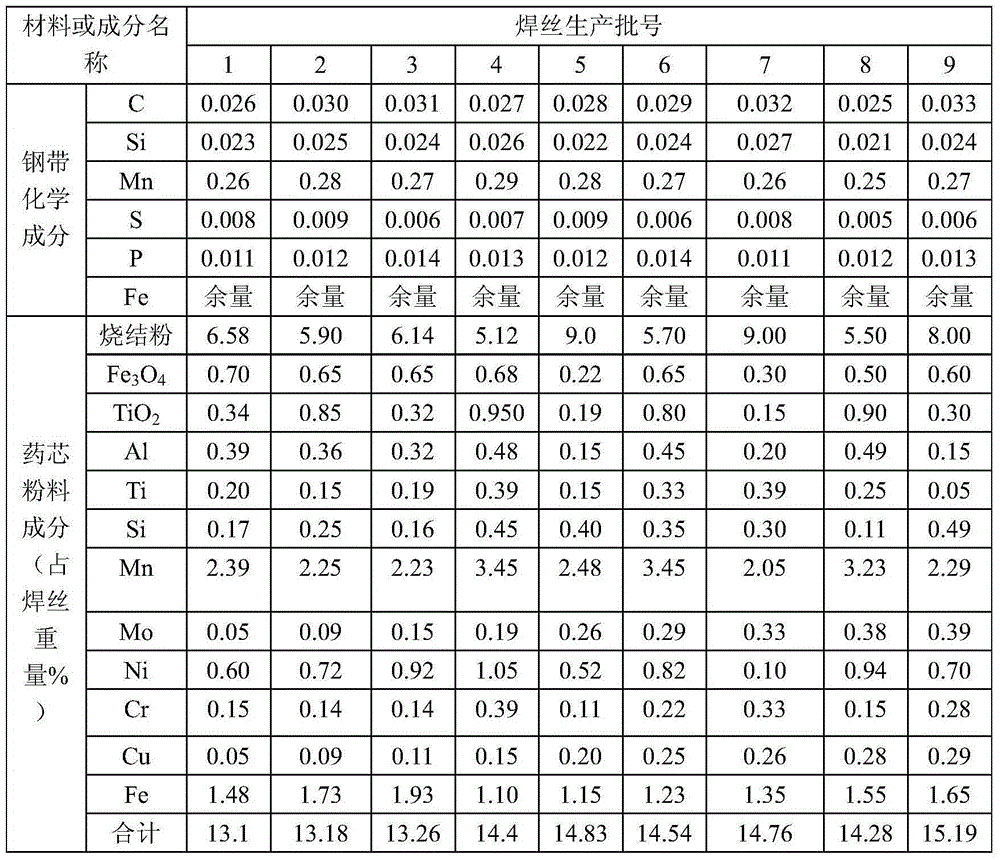

[0047] Table 1 Example——10CrSiNiCu steel flux-cored wire strip composition and flux core composition (weight, %)

[0048]

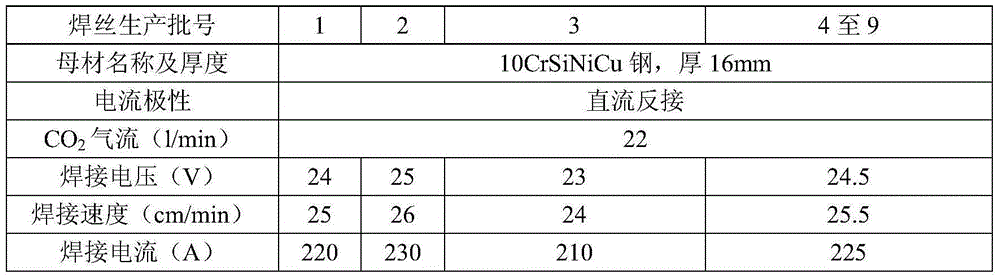

[0049] Table 2 Example - 10CrSiNiCu steel flux cored wire welding base metal and welding process parameters

[0050]

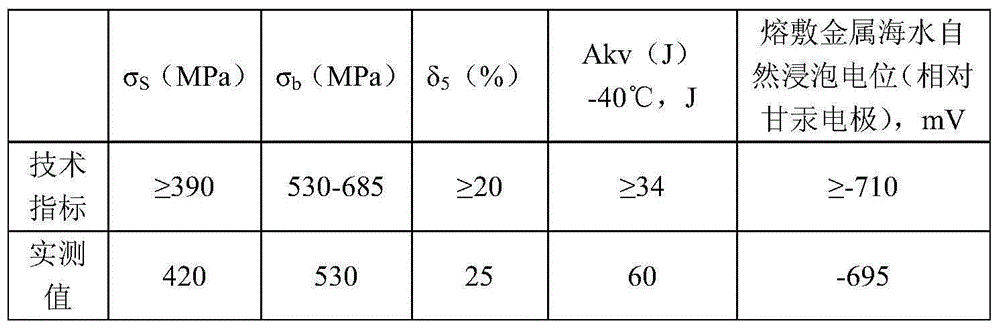

[0051] Table 3 Example——10CrSiNiCu steel flux-cored wire deposited metal properties

[0052]

[0053] Note: Charpy impact energy is the average value of five samples.

[0054]

[0055] The flux-cored welding wire made fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap