Screw conveying mechanism

A conveying mechanism and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to convey in a direction, low conveying efficiency, poor conveying effect, etc., to reduce the probability of overturning, good conveying effect, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

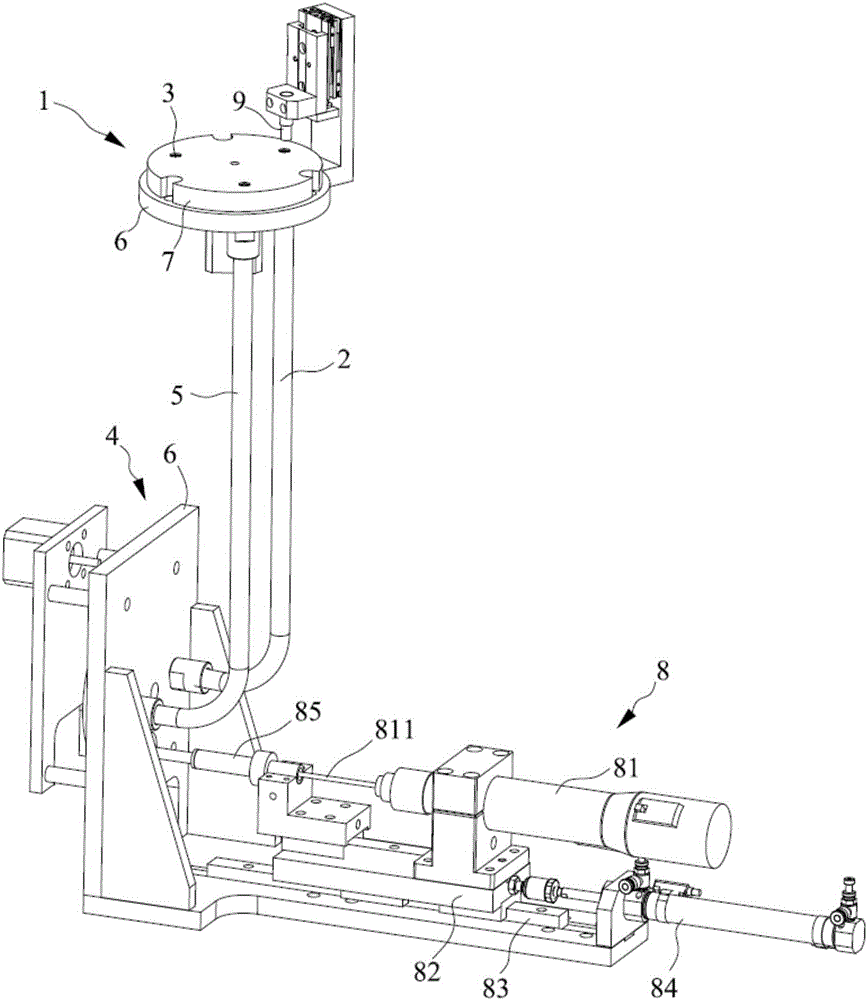

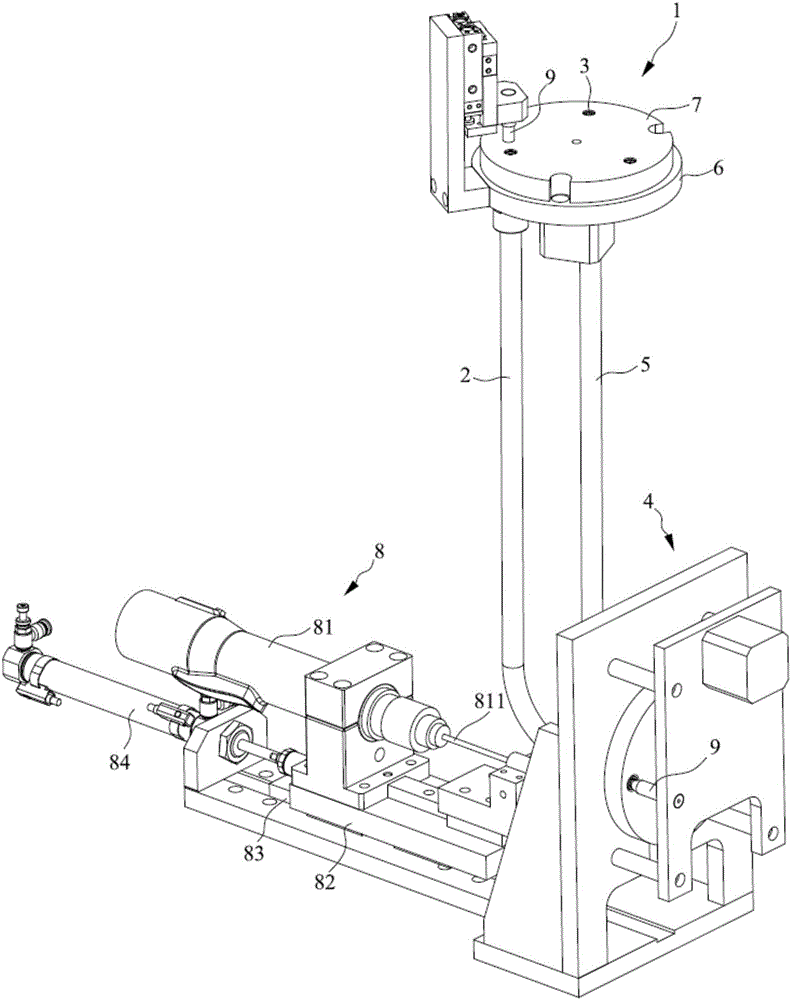

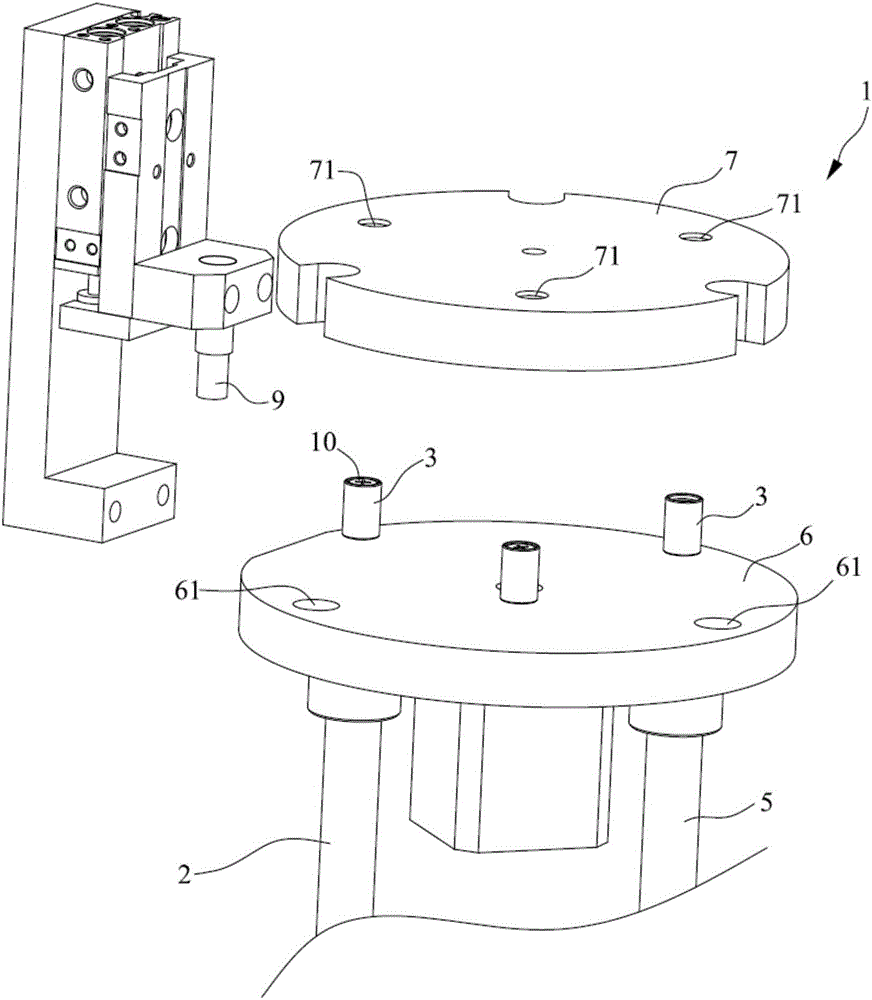

[0027] Such as Figure 1-Figure 6 As shown, this embodiment provides a screw conveying mechanism, including a feeding device 1, a feeding tube 2 and a conveying member 3 for conveying the screw 10. The feeding device 1 can be a plate structure, a block structure or other The feeding device 1 is provided with a material plate hole 71 communicating with the feeding pipe 2, and the conveying part 3 is located in the material plate hole 71 and can enter into the feeding pipe 2 and move along the feeding pipe 2. The feeding pipe 2 is in the feeding device. One end of 1 can be connected with an air blowing device, the conveying part 3 includes a housing chamber 31, and the screw 10 is fixed in the housing chamber 31, and the ratio of the longitudinal dimension to the transverse dimension of the conveying part prevents the conveying part from overturning when moving in the feeding tube. Generally speaking, when the ratio of the height to width of the conveying member 3 is not less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com