Fixture device for tenon tooth blade milling blade root

A fixture device and blade technology, which is applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of lack of versatility of fixtures and waste of cost, and achieve the effects of strong structural versatility, low manufacturing cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

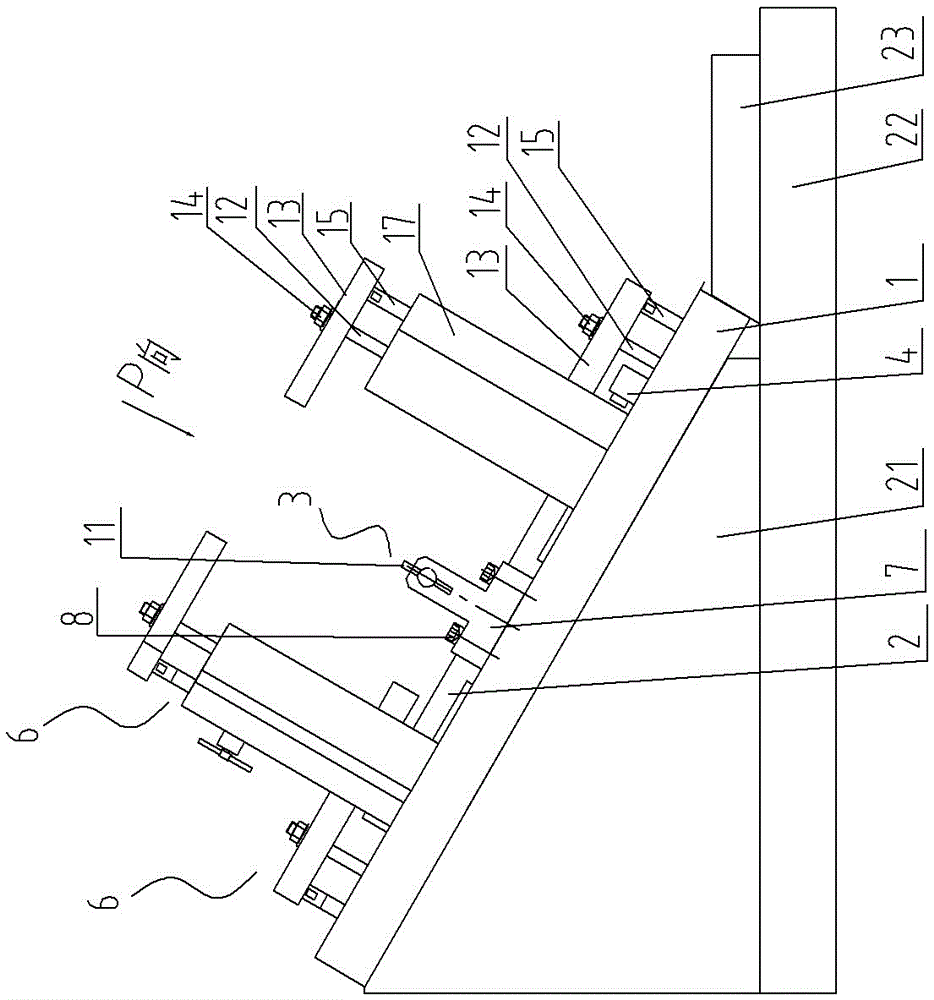

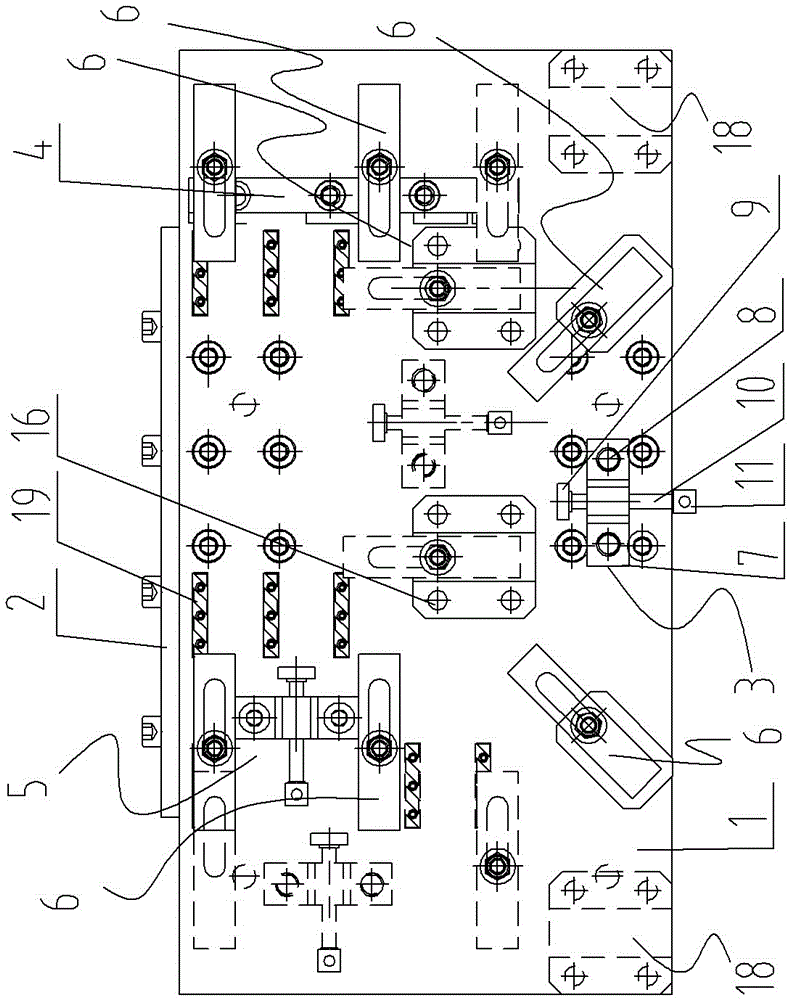

[0023] See Figure 1 to Figure 7 As shown, the fixture device used for milling the root of tenon-toothed blades includes a positioning base plate 1, and an end positioning block 2 is installed on the longitudinal rear end of the positioning base plate 1, corresponding to the end positioning block 2, and an end positioning block 2 is installed on the positioning base plate 1. Top tightening mechanism 3; side positioning block 4 is installed on the lateral side of positioning base plate 1, corresponding to side positioning block 4, and side portion tightening mechanism 5 is installed on positioning bottom plate 1; At the tight mechanism 5 and the side positioning block 4 places, a movable platen mechanism 6 is installed on the positioning base plate 1; the end tightening mechanism 3 and the side tightening mechanism 5 all include support seats 7 that are flexibly connected to the positioning base plate 1, There are threaded holes on the bottom plate 1, and then the first screw 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com