Deformable lift and buoyancy integrated aircraft aerodynamic configuration

An aerodynamic shape, aircraft technology, applied in aircraft parts, fuselage, weight reduction and other directions, can solve problems such as poor maneuverability, large additional weight, wing deformation, etc., achieve wind resistance performance and maneuverability, reduce aircraft weight, The effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

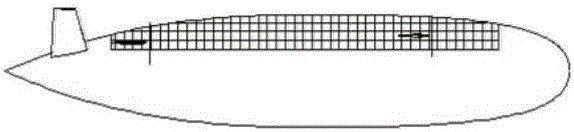

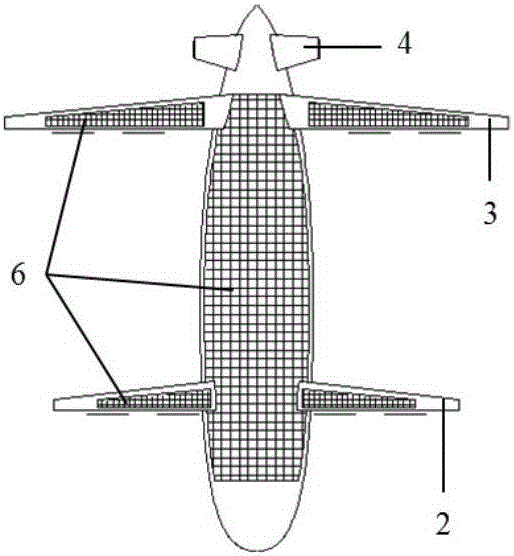

[0028] The design maximum hovering height h=15km and the maximum volume V=140000m 3 , the ratio of the maximum volume to the minimum volume of the fuselage K=6.3.

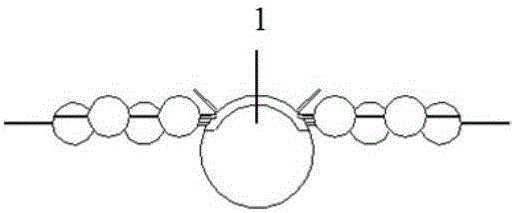

[0029] The chord length of each truss is obtained by calculating the geometric relationship between the deformed trusses: assuming that the distance between the two revolving pairs 12 on the wing spar 10 is a, the chord length of the first truss H1 and the fifth truss H5 is 1.11a, the The chord length of the third truss H3 and the fourth truss H4 is 0.94a, and the chord length of the third truss H3 is 0.85a. Assume that the angle between the first truss H1 and the vertical direction is θ. When the aircraft is parked on the ground, θ=28.4°. During the deformation and ascent of the aircraft, when the flight altitude is 11km, θ reaches the maximum value of 51.6°. At this time, the truss H2, Both H3 and H4 are in the horizontal position. When the flying height reaches the maximum hovering height of 15km, θ=30.4°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com