An automatic vacuum packaging machine

A technology of vacuum packaging machine and packaging machine, which is used in packaging, packaging, transportation packaging and other directions under vacuum/special atmosphere, can solve the problems of low work efficiency, slow system running speed, grasping shaking, etc. The effect of fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

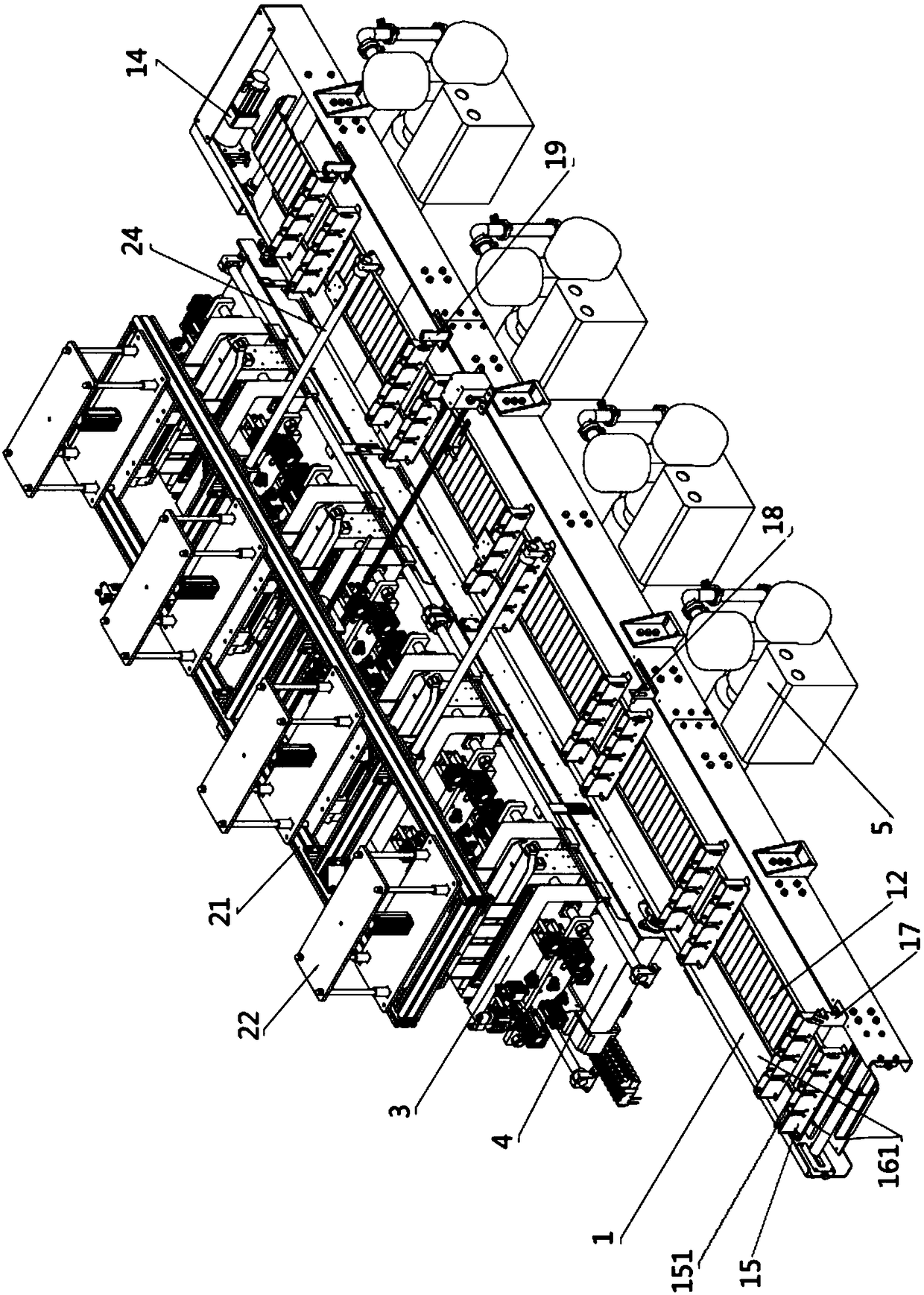

[0032] The following takes the eight-chamber automatic vacuum packaging machine as an example and introduces it in detail with the accompanying drawings.

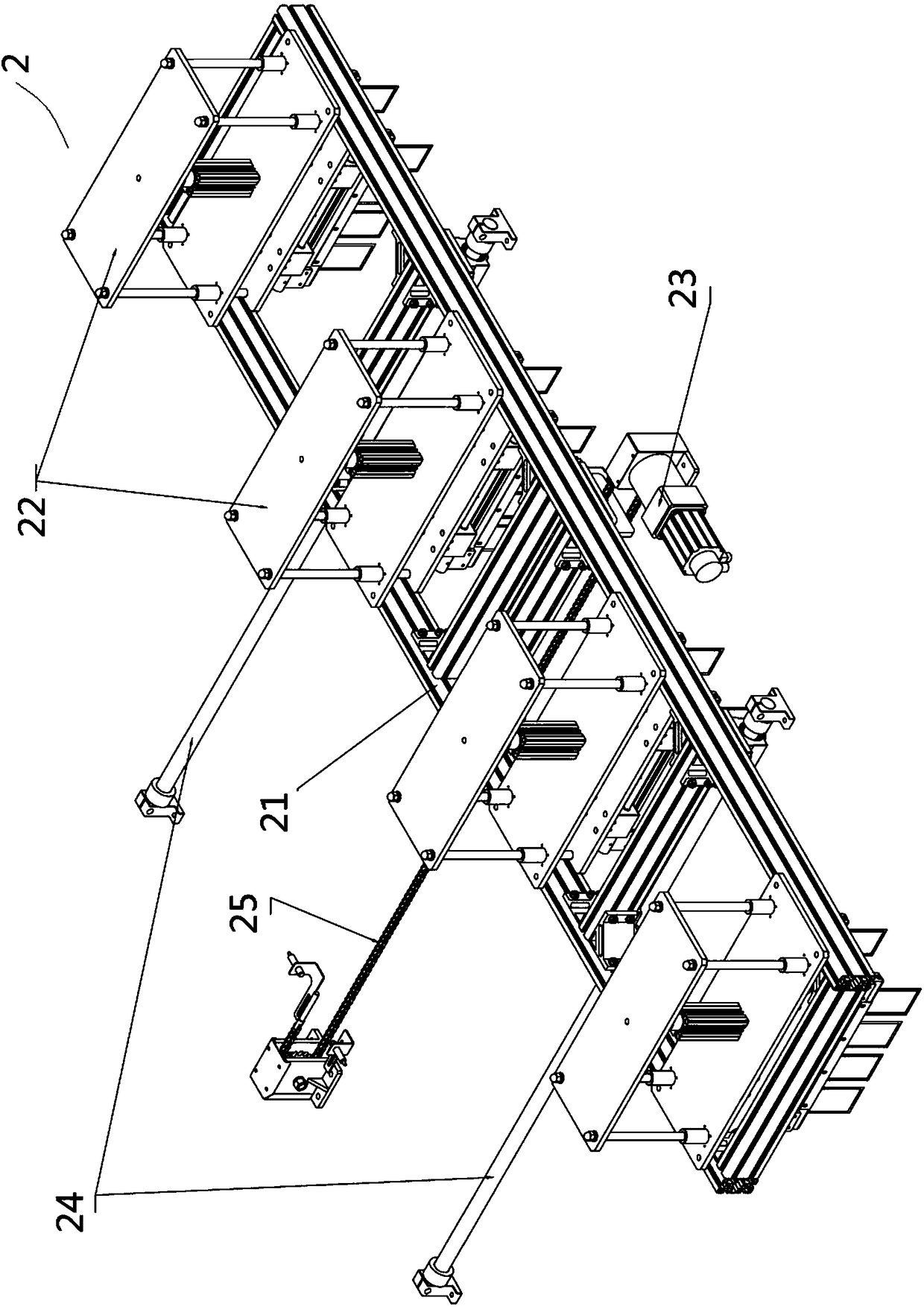

[0033] like figure 1 As shown, the eight-chamber automatic vacuum packaging machine includes a conveying chain plate device 1, an output device 4 located on one side of the conveying chain plate device, a vacuum sealing device 3 located above the output device, and a bag grabbing device 2 located above the vacuum sealing device .

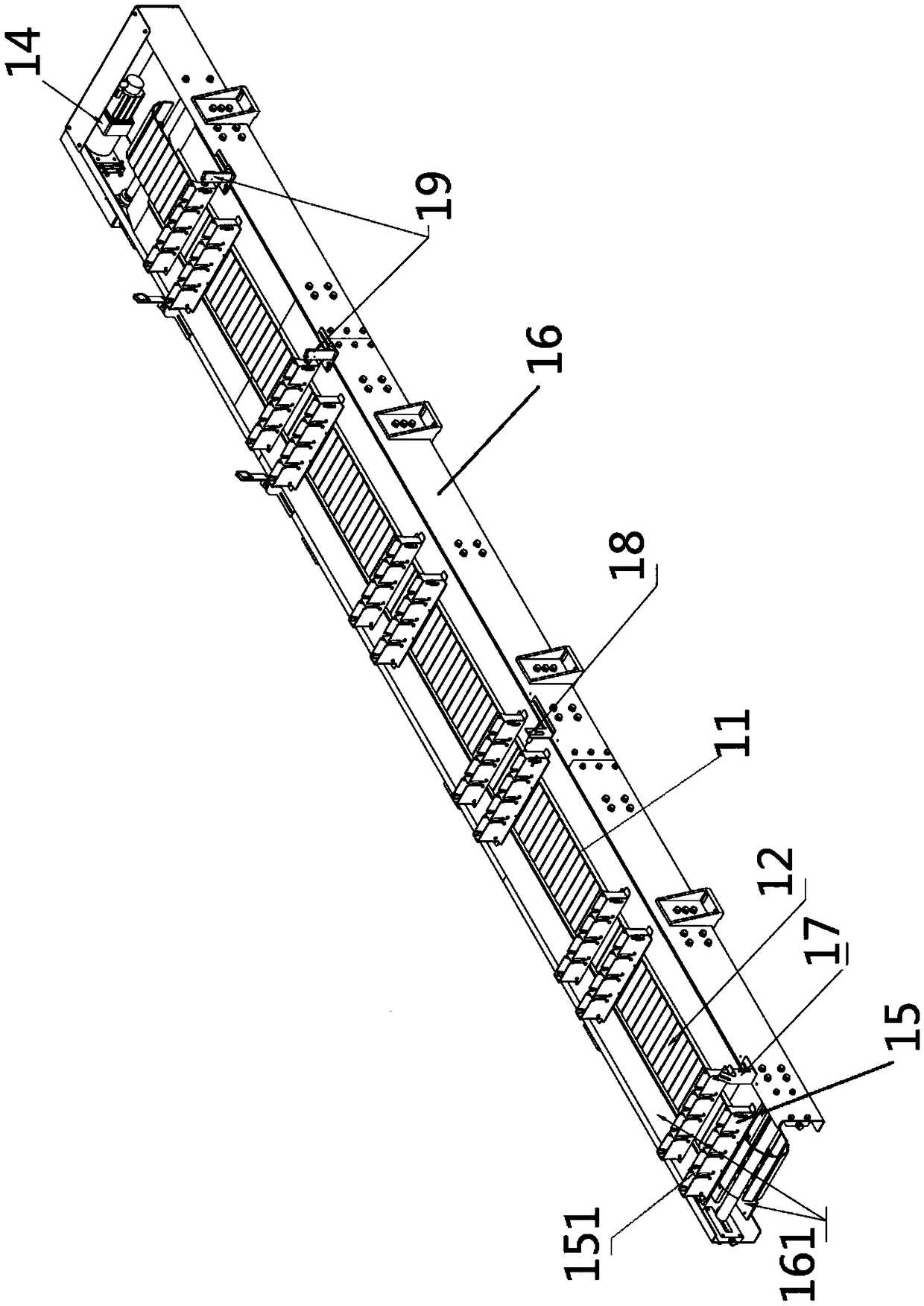

[0034] like figure 2 As shown, the conveying chain plate device 1 includes a bracket 16, sprockets installed at both ends of the roller on the bracket 16, a chain 11 connected to the sprocket and running in the horizontal direction, a chain plate 12 fixed on the chain by buckles, The servo motor A14 connected to the shaft where the chain is located and the bag slot 15 fixed on the chain plate, the bag slot is vertically fixed on the conveyor chain plate by bolts, there are 4 sets of bag slots,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com