Antiskid conveying belt

A conveyor belt, anti-slip technology, applied in the field of conveyor belts, can solve problems such as slipping, low work efficiency, and operator inconvenience, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

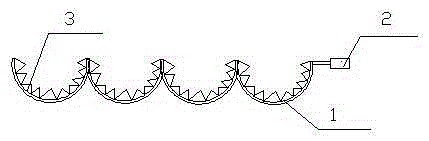

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a non-slip conveyor belt, including a conveyor belt 1 and a motor 2 that drives the conveyor belt to run, the conveyor belt 1 is a wave-shaped conveyor belt, and each of the two sides of the wave-shaped conveyor belt 1 is provided with a rack 3.

[0011] In the present invention, the conveyor belt 1 is designed to be wave-shaped, and racks 3 are provided on both sides of the conveyor belt 1, which can effectively prevent the items on the conveyor belt 1 from slipping down during the conveying process and affect the conveying efficiency. Also brought very big inconvenience and simple in structure, easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com