Bag loading and unloading device for flour packaging machine

A bag loading and unloading and packaging technology is applied in the field of loading and unloading bag devices for flour packaging machines, which can solve the problems of affecting flour production efficiency and progress, large amount of dust in manual packaging, low packaging efficiency, etc. Avoid clumping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

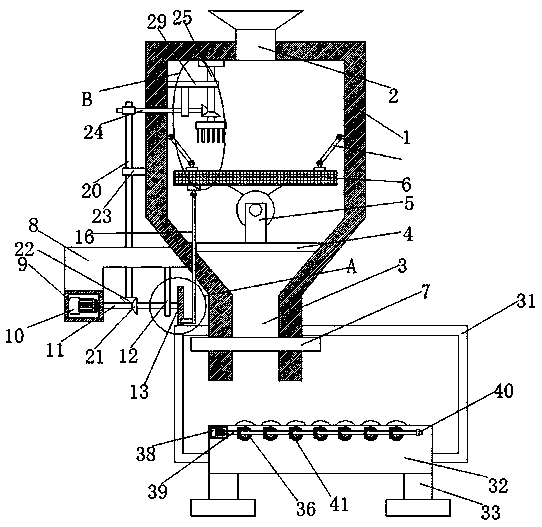

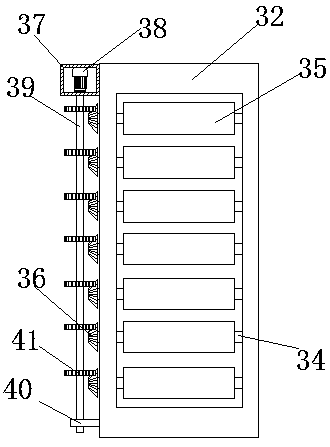

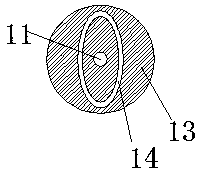

[0028] refer to Figure 1-5 , a loading and unloading bag device for a flour packaging machine, comprising a processing box 1, the top of the processing box 1 is provided with a material inlet 2, the bottom of the processing box 1 is provided with a discharge port 3, and a filter plate 6 is movably installed in the processing box 1 , the agglomerated flour can be blocked, the bottom of the processing box 1 is fixedly installed with a fixed ring 7, one side of the processing box 1 is fixedly installed with a fixed plate 8, and the bottom of the fixed plate 8 is fixedly installed with a first installation box 9, the second A first drive motor 10 is fixedly installed in the installation box 9, a drive shaft 11 is fixedly installed on the output shaft of the first drive motor 10, the top of the first fixed rod 12 is fixedly installed on the bottom of the fixed plate 8, and the drive shaft 11 rotates Installed on the bottom of the first fixed rod 12, one side of the drive shaft 11 ...

Embodiment 2

[0039] refer to Figure 1-5 , a loading and unloading bag device for a flour packaging machine, comprising a processing box 1, the top of the processing box 1 is provided with a material inlet 2, the bottom of the processing box 1 is provided with a discharge port 3, and a filter plate 6 is movably installed in the processing box 1 , the agglomerated flour can be blocked, the bottom of the processing box 1 is fixedly installed with a fixed ring 7 by welding, one side of the processing box 1 is fixedly installed with a fixed plate 8 by welding, and the bottom of the fixed plate 8 is fixed with a second screw. An installation box 9, the first drive motor 10 is fixedly installed by screws in the first installation box 9, the output shaft of the first drive motor 10 is fixedly installed with a drive shaft 11 by welding, and the bottom of the fixed plate 8 is fixedly installed with a On the top of the first fixed rod 12, the drive shaft 11 is rotatably mounted on the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com