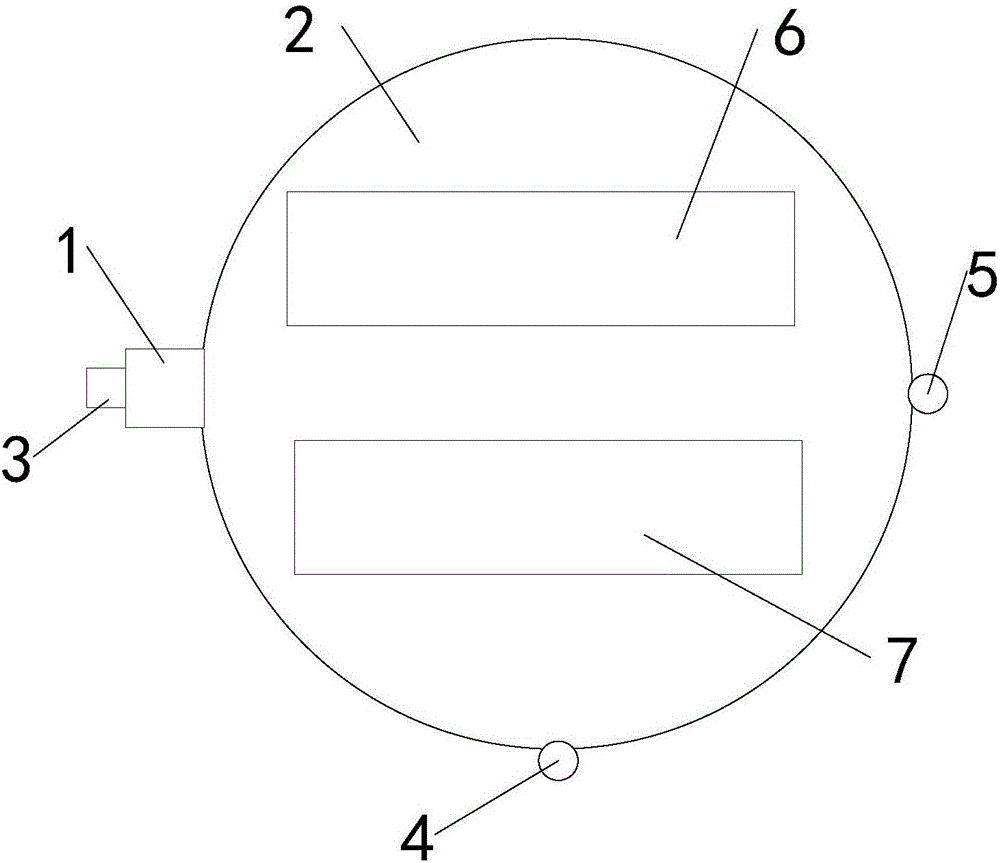

Conveying chain rotating platform rotation control method and rotation control device

A technology of rotation control device and rotating platform, which is applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problem of inaccurate target stop position, and achieve the effect of improving rotation control precision and fast and accurate stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

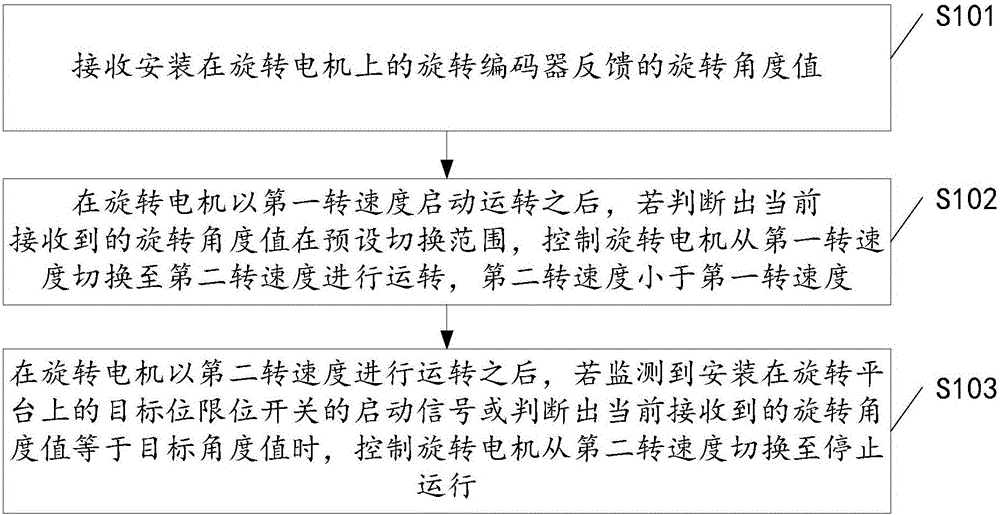

[0043] Firstly, according to the rotation angle value fed back by the rotary encoder within the range of -0.45° to 0.45°, the zero limit switch 5 can detect the start signal, and the rotary motor rotates the rotary platform at a speed of 14 degrees / second at a speed of 80%. The angular velocity rotates clockwise (-90 degrees);

[0044] Next, the PLC compares the rotation angle value fed back by the rotary encoder with the set value of the deceleration position -70 degrees. When the rotation angle value fed back by the PLC to the rotary encoder is equal to -70 degrees, indicating that the rotary platform reaches the deceleration point, the PLC The control system issues a low-speed rotation command to the rotating motor, and the rotating motor switches from 80% to 35% of the speed according to the low-speed rotation command, so that the rotating platform rotates to the target stop position (-90 degrees) at an angular velocity of 6 degrees per second ; Before the rotating platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com