A fully automatic loading machine

A car loading machine, fully automatic technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of large workload of unstacking and loading, large number of workers required, small range of unstacking and loading, and achieve saving on loading and unloading. The effect of reducing driving time, improving work efficiency, and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the drawings.

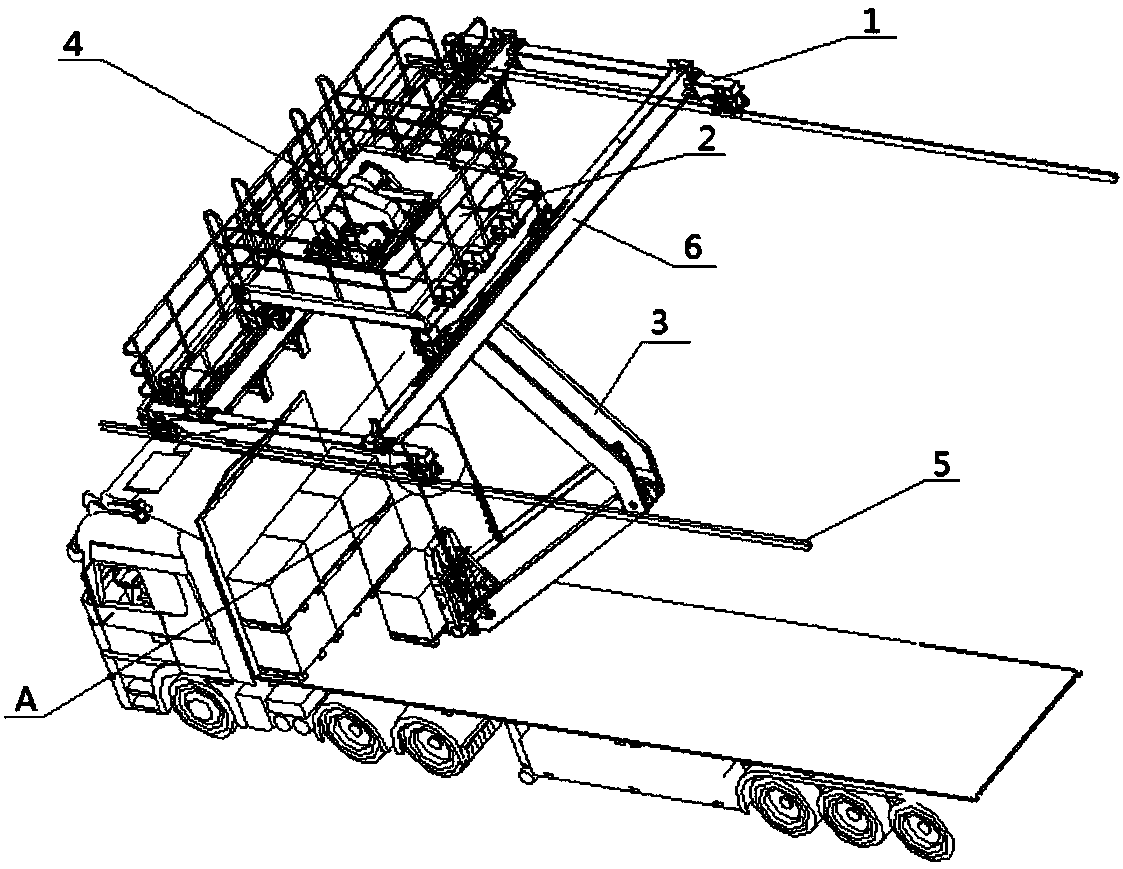

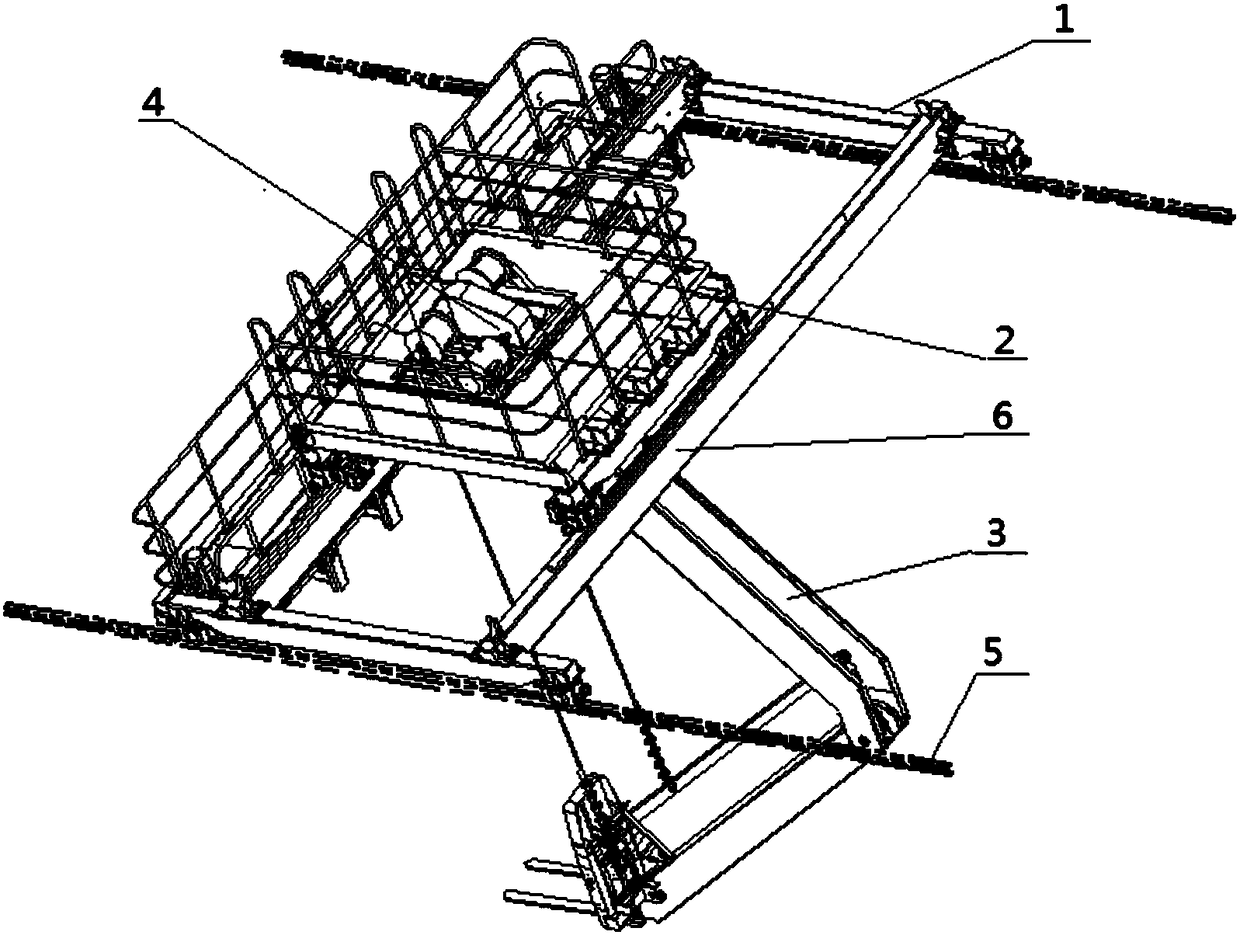

[0030] A fully automatic loading machine includes: rail moving cart 1, lifting device 4, cart guide rail 5, trolley guide rail 6, rail moving cart 2 and mechanical arm 3,

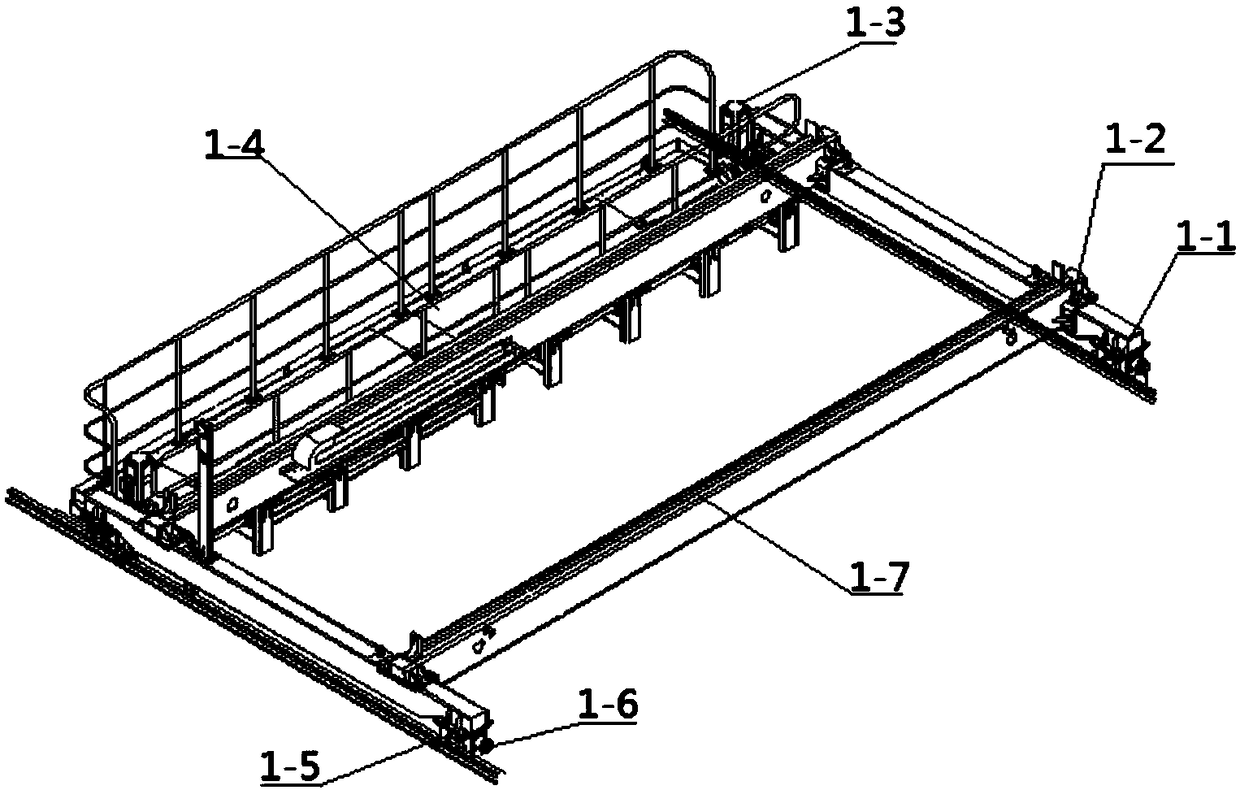

[0031] The track mobile cart 1 includes: a cart running mechanism 1-1, a cart main frame 1-2, and a cart driving mechanism 1-3;

[0032] A cart running mechanism 1-1 is installed at the bottom of the cart main frame 1-2, and the cart driving mechanism 1-3 drives the cart running mechanism 1-1 to move linearly along the cart guide rail 5;

[0033] The track mobile trolley 2 includes: a trolley main frame 2-1, a trolley running mechanism 2-3, and a trolley driving mechanism 2-6;

[0034] A trolley running mechanism 2-3 is installed at the bottom of the trolley main frame 2-1, and the trolley driving mechanism 2-6 drives the trolley running mechanism 2-3 to move linearly along the trolley guide rail 6. The trolley guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com