Transformation method for coke dry quenching dedusting system and coke pushing dedusting system

A dust removal system and coke CDQ technology, which is applied in coke cooling, coke oven, furnace fouling prevention/removal, etc., can solve the problems of high operating cost and large area occupation, and achieve the effect of solving large area occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

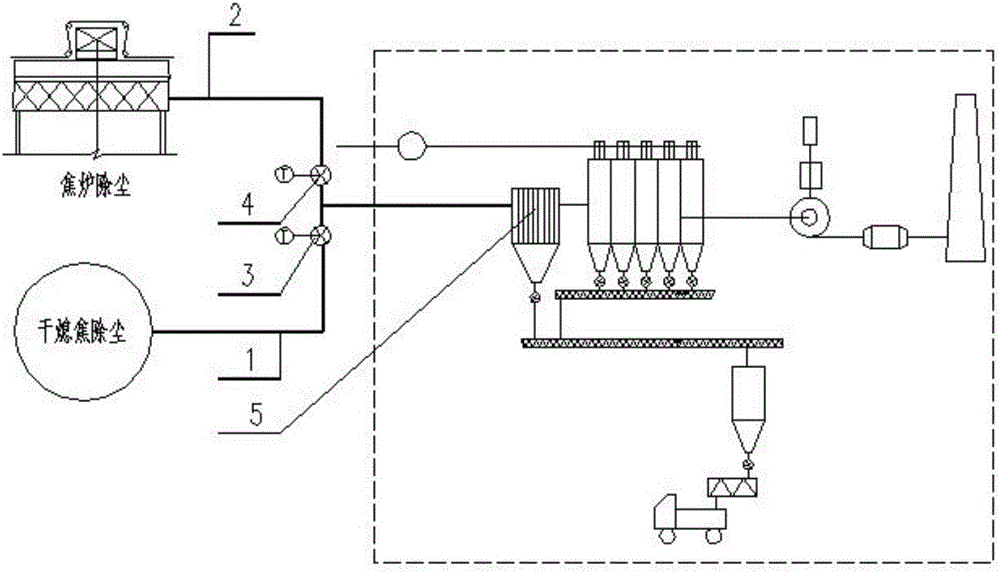

Image

Examples

Embodiment Construction

[0009] Before selecting the combination of the coke pusher dust removal system and CDQ dust removal system to share a set of dust removal ground station technology, firstly determine the amount of flue gas generated by CDQ, its finished product transfer system, and push coke through calculation, and then according to the coke The working system of furnace coke pushing and CDQ determines the production sequence of the two production processes, and makes a combined sequence table, and then judges whether there is any overlap in the production process according to the sequence table. If there is no overlap, follow the The equipment parameters of the dust removal ground station are selected for the maximum air volume of the two processes. If there is overlap, the equipment parameters of the dust removal ground station are designed according to the simultaneous operation conditions, and finally the corresponding valves and automatic control detection devices are set.

[0010] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com