Reduction steam box

A technology of steamer and box body, which is applied in textile and papermaking, textile processing machine accessories, textile material processing and other directions, can solve problems such as inability to accurately adjust the size of the seal, inability to effectively monitor the humidity of the steamer, uneven temperature and humidity distribution, etc. , to achieve the effect of improving steam utilization, ensuring consistency and preventing steam overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

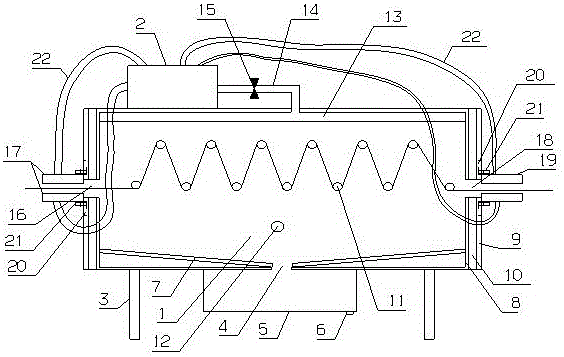

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] A reduction steam box includes a steam box body 1, a steam generator 2 and a controller. The controller is provided with a storage module and a control module, and the high humidity value and the low humidity value are stored in the storage module. The bottom surface of the steamer body 1 is provided with a support leg 3, a waste liquid outlet 4 and a waste liquid storage tank 5, the waste liquid outlet 4 communicates with the waste liquid storage tank 5, and the bottom of the waste liquid storage tank 5 is provided with a liquid outlet, and the liquid outlet The mouth is provided with an end cover 6, and the side of the waste liquid storage tank 5 is provided with a side door. A liquid guide plate 7 is provided at the inner bottom of the steamer body 1 , and the liquid guide plate 7 gradually slopes downward from both sides of the steamer body 1 towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com