A cast-in-place beam without temporary pier support

A technology of cast-in-place beams and temporary piers, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of many structural measures, complicated installation and demolition, damage to pier bodies, etc. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

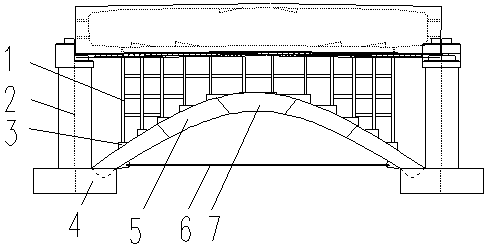

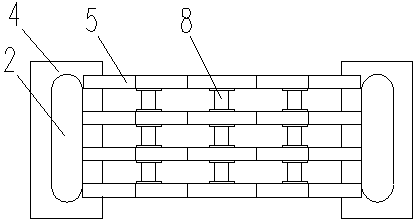

[0035] Such as figure 1 , figure 2 As shown, the invention discloses a cast-in-place beam without a temporary pier support, comprising

[0036] A number of arched underframes spanning in parallel between two adjacent piers and located below the cast-in-place beams;

[0037] a number of longitudinal connectors, the longitudinal spans of which are attached to all arched underframes, and

[0038] The bowl buckle support 1 stands vertically between the arched underframe and the bottom of the cast-in-place beam.

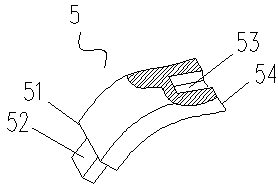

[0039] The two ends of the arched underframe are supported on the upper end surface of the pier body 2 bearing platform 4, and are fixed and spliced by a number of symmetrical arch sections; each arch section has a front splicing end surface 54 and a rear splicing end surface 51, and the adjacent arch sections The space is connected through front and rear splicing end faces 54, 51. When the number of arch segments is an odd number, such as image 3 , Figure 4 As ...

Embodiment 2

[0044] Such as image 3 , Figure 5 , Image 6 As shown, on the basis of Embodiment 1, the number of arch segments is an even number, and the front splicing end faces 54 of all arch segments have a groove 53 extending in the arch segment, and the rear splicing end face 51 has a concave groove 53 that is consistent with the adjacent arch segment. The groove 53 is embedded in the matching convex body 52, and the adjacent arch segments rely on the cooperation between the groove 53 and the convex body 52 to insert and cooperate with each other. It is the same shape as the arch segment 5 on one side of the embodiment. The arched underframe, and the requirements for the splicing of the splicing surfaces between the arch sections are not high, and it is suitable for cast-in-place beam brackets with low requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com