CL spatial separation type high-water-level water inlet valve

A space isolation and water inlet valve technology, which is applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of low water level, unsatisfactory cleaning and replacement effects, etc., and achieve the effect of improving the replacement rate and enhancing the cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

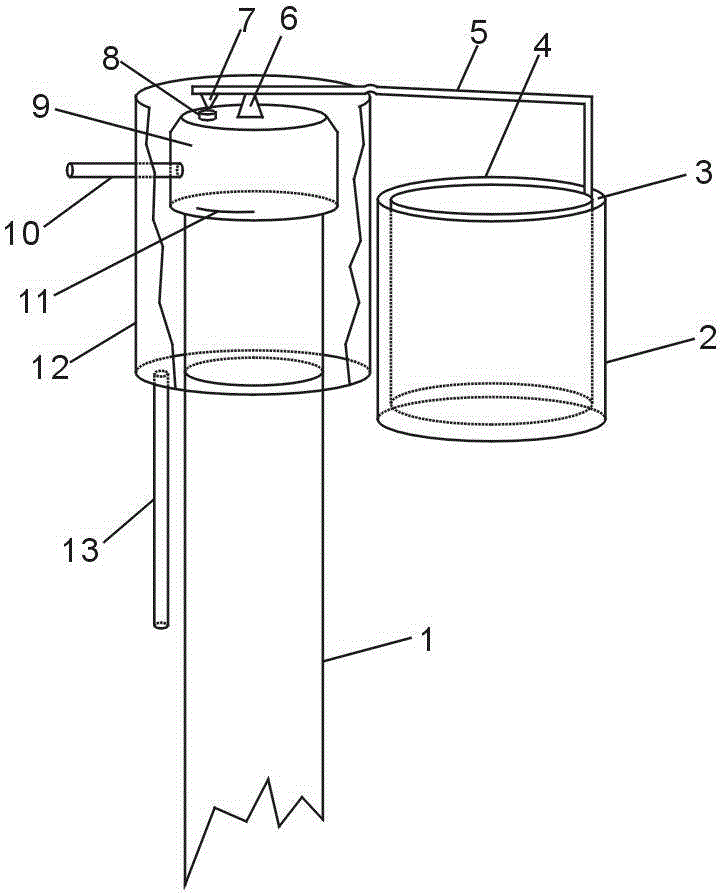

[0017] figure 1 The specific implementation manner of the CL line space isolation high water level water inlet valve of the present invention is shown. A dip bucket 12 is arranged at the upper end of the water inlet valve main body 1 . The CL line 11 and the differential pressure valve 9 are isolated in the immersion barrel 12 . The water supply pipe 10 on the differential pressure valve 9 passes through the side wall of the soaking bucket 12, the pressure relief hole 8 coincides with the blockage 7, and the fulcrum 6 is movably connected with the lever 5. A bottom water pipe 13 is formed at the lower end of the soaking tub 12 . The other end of the lever 5 is connected to the float 4. The water surface after the float 4 floats is set as the highest water storage surface 3. The float cover 2 is fixed on the soaking bucket 12 or the main body 1 of the water inlet valve.

[0018] When designing the immersion bucket 12, the height after installation must be higher than the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com