Intermediate bunker of biomass boiler taking straw as fuel

A technology for biomass boilers and intermediate silos, applied in the field of intermediate silos, can solve problems such as slopping and jamming, and achieve the effects of avoiding slopping, jamming, and shutdown accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

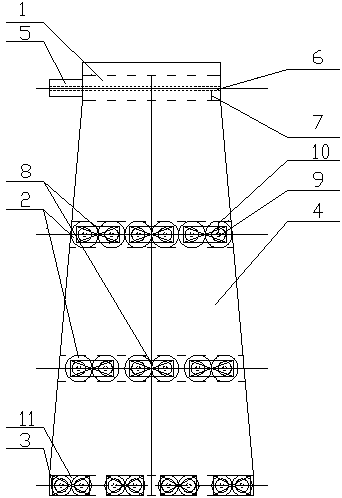

[0014] Embodiment: The intermediate silo of the biomass boiler using straw as fuel provided by the present invention is tried out on a 75t / h double-grate biomass boiler, and the front part of the boiler is installed. The fuel is rice straw, and the average length of the straw ranges from 0.8 to 1.2m. figure 1 It is a schematic diagram of the intermediate feed bin of the biomass boiler using straw as fuel in the present invention. The silo is in the shape of a square platform with a large top and a small bottom, facing the direction of the boiler, the angle between the front and rear sides and the vertical direction is 3°, and the angle between the left and right sides and the vertical direction is 5°. The thorns of the uniform ratchet, that is, the length of thorns A, is 0.4m, driven by the speed-regulating motor and planetary reducer; the thorns of the middle ratchet, that is, the length of thorns B, 0.3m, are also driven by the speed-regulating motor and planetary reducer; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com