Mounting method of wall type energy dissipation device

An installation method and energy dissipator technology, which are used in protective buildings/shelters, building components, earthquake-proof and other directions, can solve the problem of high cost of wall-type energy dissipator connectors, difficult to install accurately, quickly, and unclear force transmission. and other problems, to achieve the effect of easy maintenance and replacement, convenient and precise installation accuracy, and clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

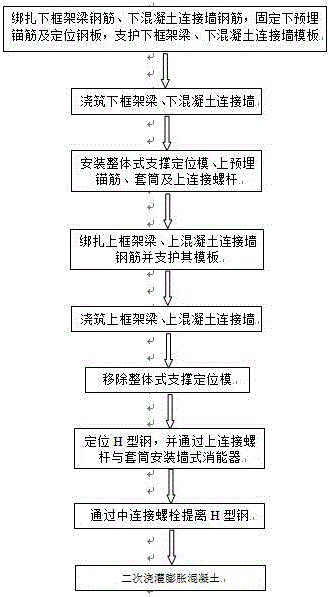

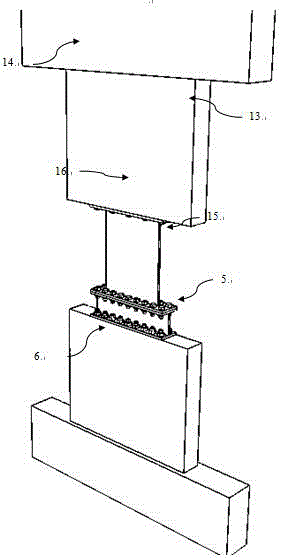

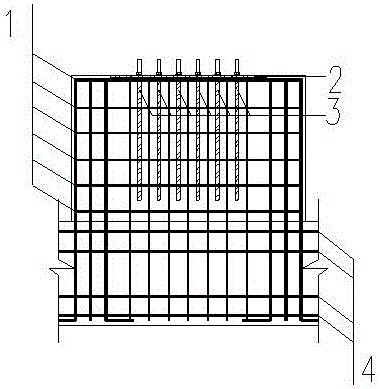

[0032] Embodiment 1: as Figure 1-12 As shown, the connection mode of the wall-type energy dissipator of the present invention adopts the cast-in-place concrete connection wall as the connection member of the energy dissipator, and its installation method is generally realized in this way: firstly, the lower frame beam 4 and the lower concrete connection wall steel bar 1 are bound, Then fix the pre-embedded anchor bar 3 and the positioning steel plate 2, then support the formwork of the lower frame beam 6 and the lower concrete connecting wall 5, then pour the lower frame beam 6 and the lower concrete connecting wall 5, and then install the adjustable support positioning formwork 9 (that is, the integral support positioning formwork), the upper pre-embedded anchor bar 7, the inner threaded sleeve 8 and the upper connecting screw 12, then bind the upper frame beam 14, the formwork of the upper concrete connecting wall 13 and support the steel cage, and then pour The upper frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com