Fixed type spring gas lift valve

A gas lift valve, fixed technology, used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of inability to supply annular protective fluid, inability to operate, limited pressure bearing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0022] In order to make the purpose, technical solution and effect of the present invention clearer, the following will further describe in detail the embodiments of the present invention in conjunction with the accompanying drawings.

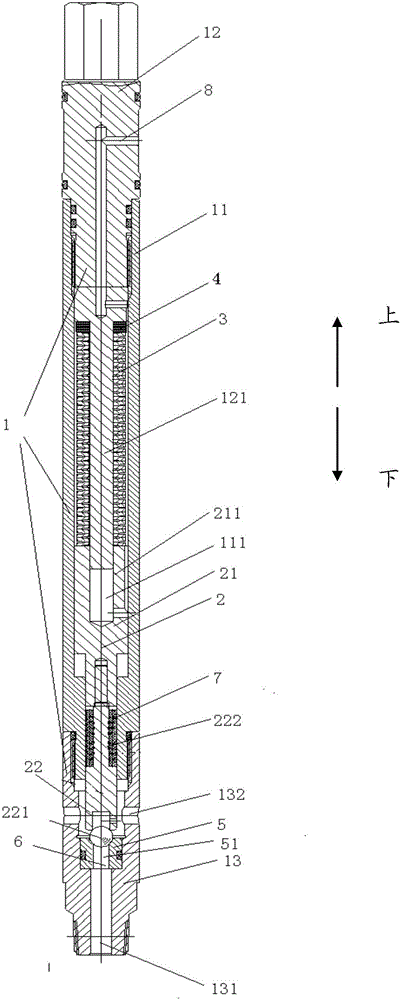

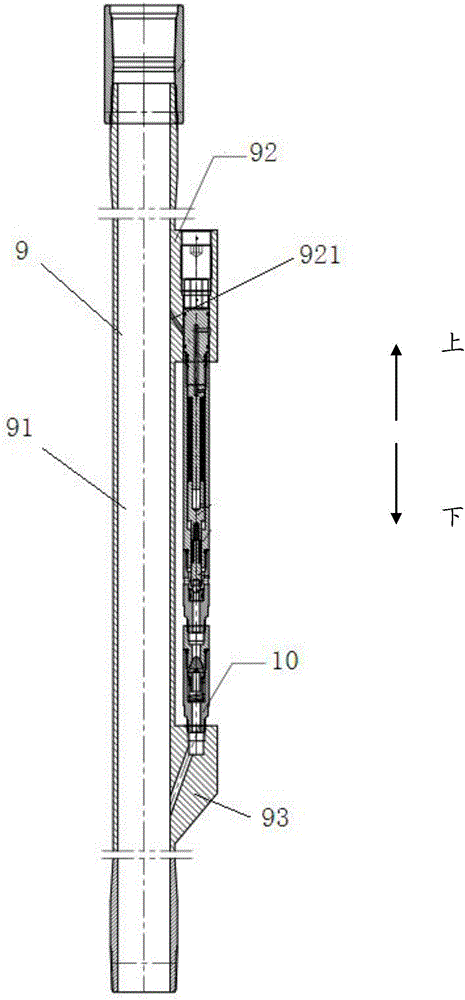

[0023] The invention provides a fixed spring gas lift valve, such as figure 1 As shown, it includes: a shell assembly 1, which includes a tubular body 11 with an inner cavity 111, an upper joint 12 located at the upper end of the tubular body 11 and a lower joint 13 located at the lower end of the tubular body 11, and the lower joint 13 is respectively provided with There is an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com